Method for manufacturing optical film

A manufacturing method and technology of optical film, applied in the field of optical film, to achieve the effect of reducing left-right swing, stable conveying state, and less left-right swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

[0244] Embodiments 1 to 17 correspond to the inventions of claims 1 to 4. In order to manufacture a cellulose acetate propionate film with a target dry film thickness of 80 μm by using the solution casting method for making an optical film according to the present invention, first prepare the glue pulp.

[0245] (preparation of mucilage)

[0246] 100 parts by mass of cellulose acetate propionate

[0247] (The degree of substitution of acetyl group is 1.95, the degree of substitution of propionyl group is 0.7)

[0248] 10 parts by mass of triphenyl phosphate

[0249] 2 parts by mass of ethyl phthaloyl glycol

[0250] 300 parts by mass of dichloromethane

[0251]40 parts by mass of ethanol

[0252] TINUVIN 326 (manufactured by Ciba Specialty Chemicals) 1 part by mass

[0253] AEROSIL 200V (manufactured by Japan Aerosil Co., Ltd.) 0.1 parts by mass

[0254] Put the above materials into a sealed container in sequence, and after the temperature in the container is raised fro...

Embodiment 18~23

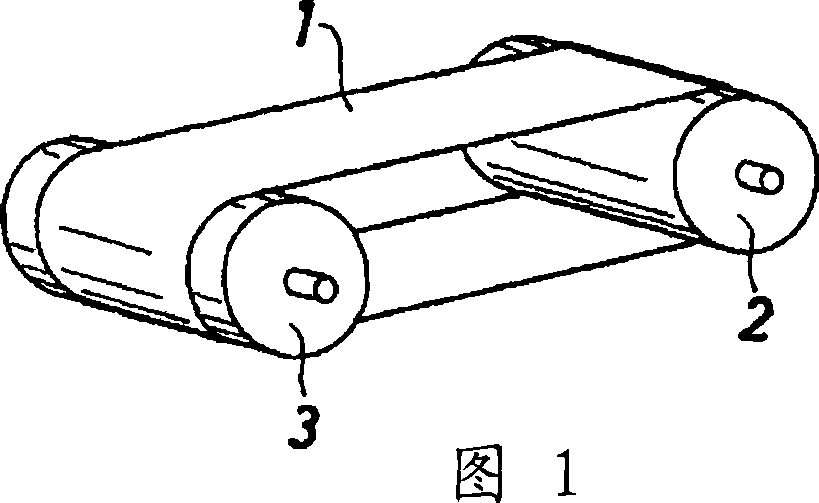

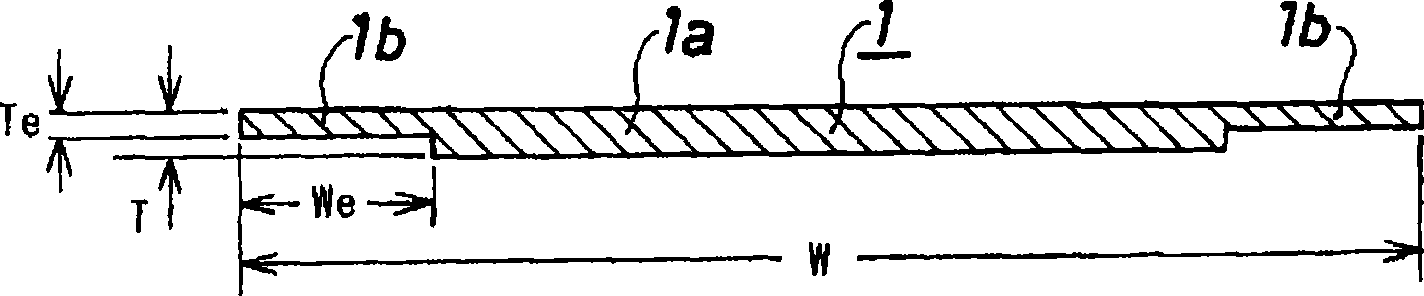

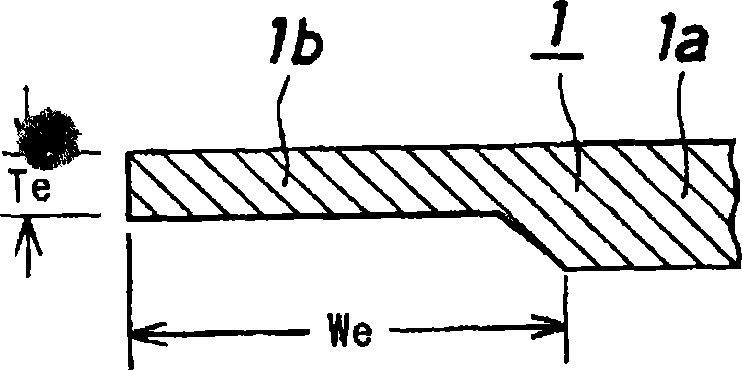

[0276] Examples 18 to 23 correspond to the inventions of claims 6 to 10, and prepared a tape test sample member (tape support) (11) having a total width of 500 mm and a length of 1000 mm. A sample part end portion (11b) is welded to one side edge of the sample part body (11a) of each test sample part (11).

[0277] As a material of the test sample member (11), SUS316 (longitudinal modulus of elasticity 220 [GPa]) was used. In addition, for the sample part end part (11b), two materials with different processing temperatures in SUS316 (longitudinal elastic modulus 220, 200 [GPa]), SUS304 (longitudinal elastic modulus 190 [GPa]), and SUS405 processing temperature were appropriately combined Different 2 kinds of materials (longitudinal elastic modulus 180, 175 [GPa]), adjust the longitudinal elastic modulus.

[0278] Here, as shown in Table 3 below, the width (We) of the sample member end portion (11b) is the width (We) of the test sample member (with support) (11) from one side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| reid vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com