Complete equipment for processing mineral matter slurry

A complete set of equipment, mineral technology, applied in the direction of clay processing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of large loss of grinding media, bulky volume, poor controllability, etc., and achieve high work efficiency and volume Small, hard precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

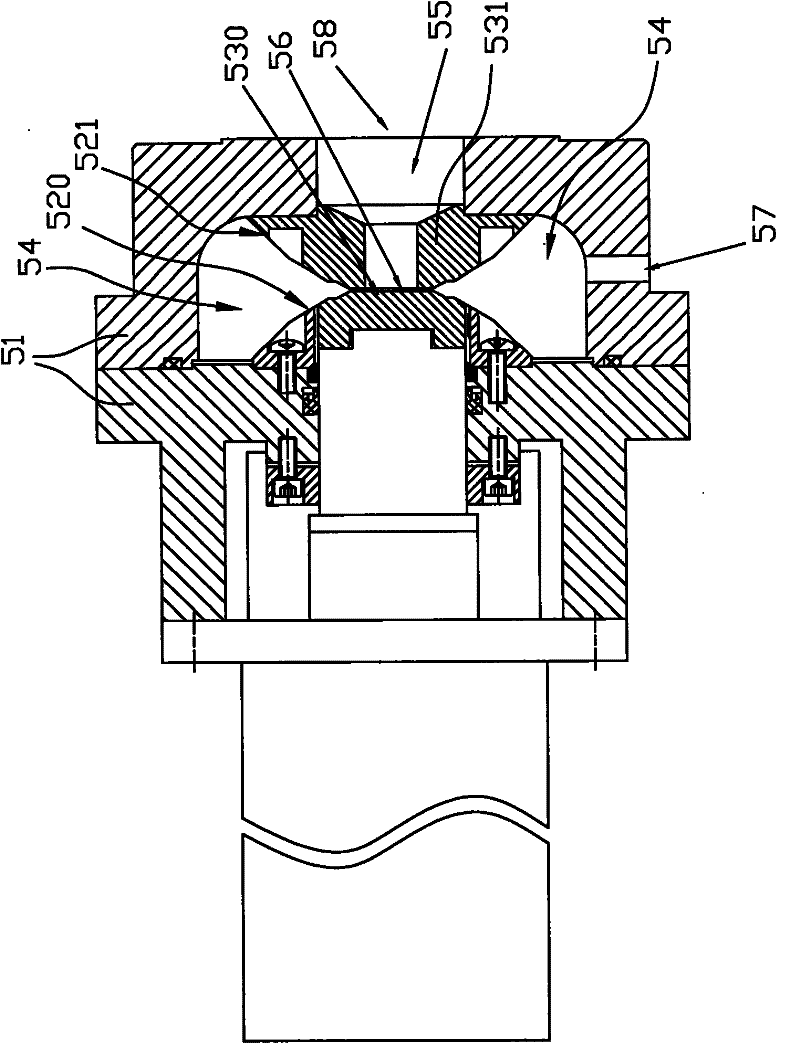

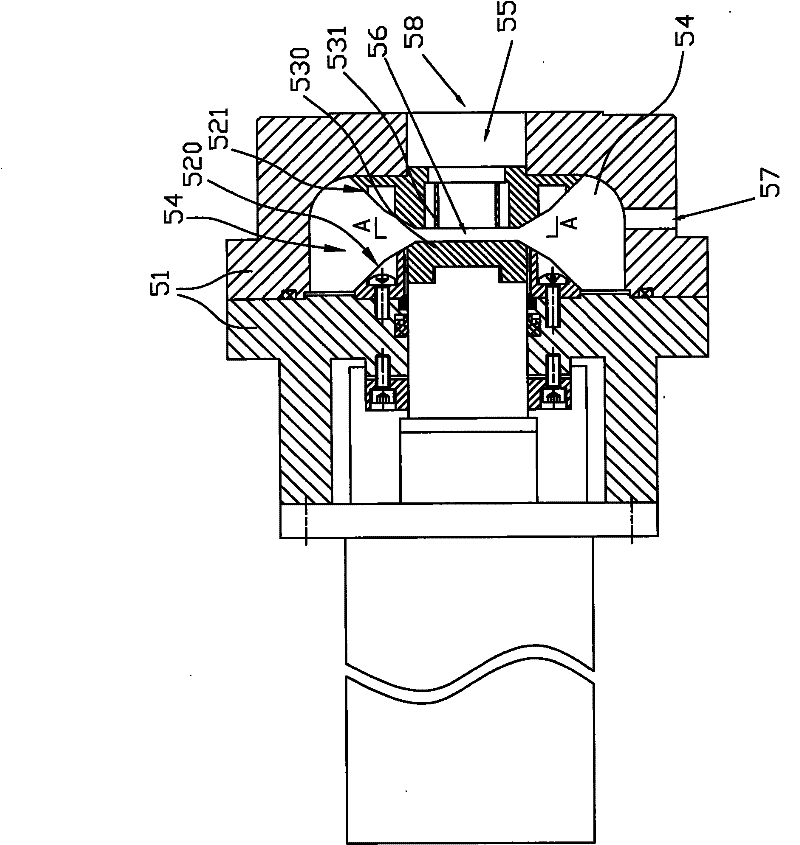

[0032] Embodiment 1: a kind of mineral slurry processing complete set of equipment, such as figure 1 As shown, it includes a mineral crushing and grinding line A, an additive solution modulation line B, a mineral rough slurry line C for mixing the ground mineral powder, and a mineral that is matched with the mineral rough slurry line C Coarse pulp pressure building line D, mineral pulping line E matched with pressure building line D, mineral pulp preparation line F connected with mineral pulping line E. The pressure building line D and the matching mineral slurry line E are at least one set (such as Figure 1-Figure 3 shown).

[0033] Mineral crushing and grinding line A includes jaw crusher 1, iron remover 2 connected with jaw crusher 1, mill 3 connected with iron remover 2, and screw conveyor connected with mill 3 4. Raw minerals or refined minerals enter the jaw crusher 1, and after being crushed by the jaw crusher 1 to the particles required by the process, they flow th...

Embodiment 2

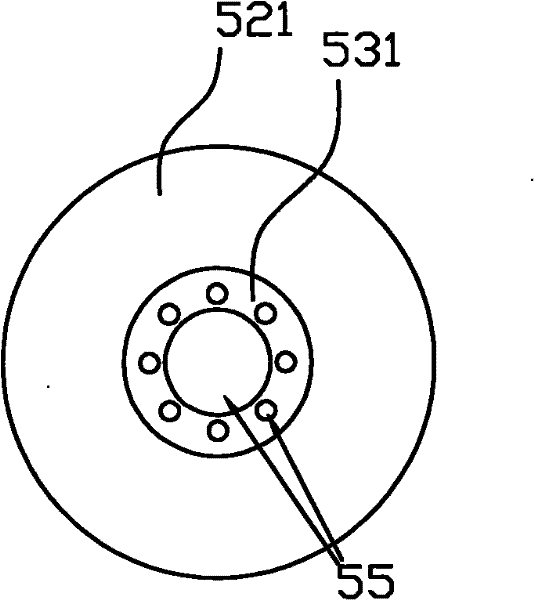

[0044] Embodiment 2: a kind of mineral slurry processing complete set of equipment, such as Figure 7 and Figure 8 As shown, a deflector plate and its valve body are provided with a plurality of through holes, and the plurality of through holes form a plurality of slurry channels 55 . All the other structures are the same as in Embodiment 1

Embodiment 3

[0045] Embodiment 3: a kind of mineral slurry processing complete set of equipment, such as Figure 6 , Figure 7 , Figure 9 , Figure 11 , Figure 13 and Figure 15 As shown, the valve body on the guide plate and the main body of the guide plate are separate structures. All the other structures are with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com