Wafer level encapsulation method of LED array encapsulation and LED encapsulation device made thereby

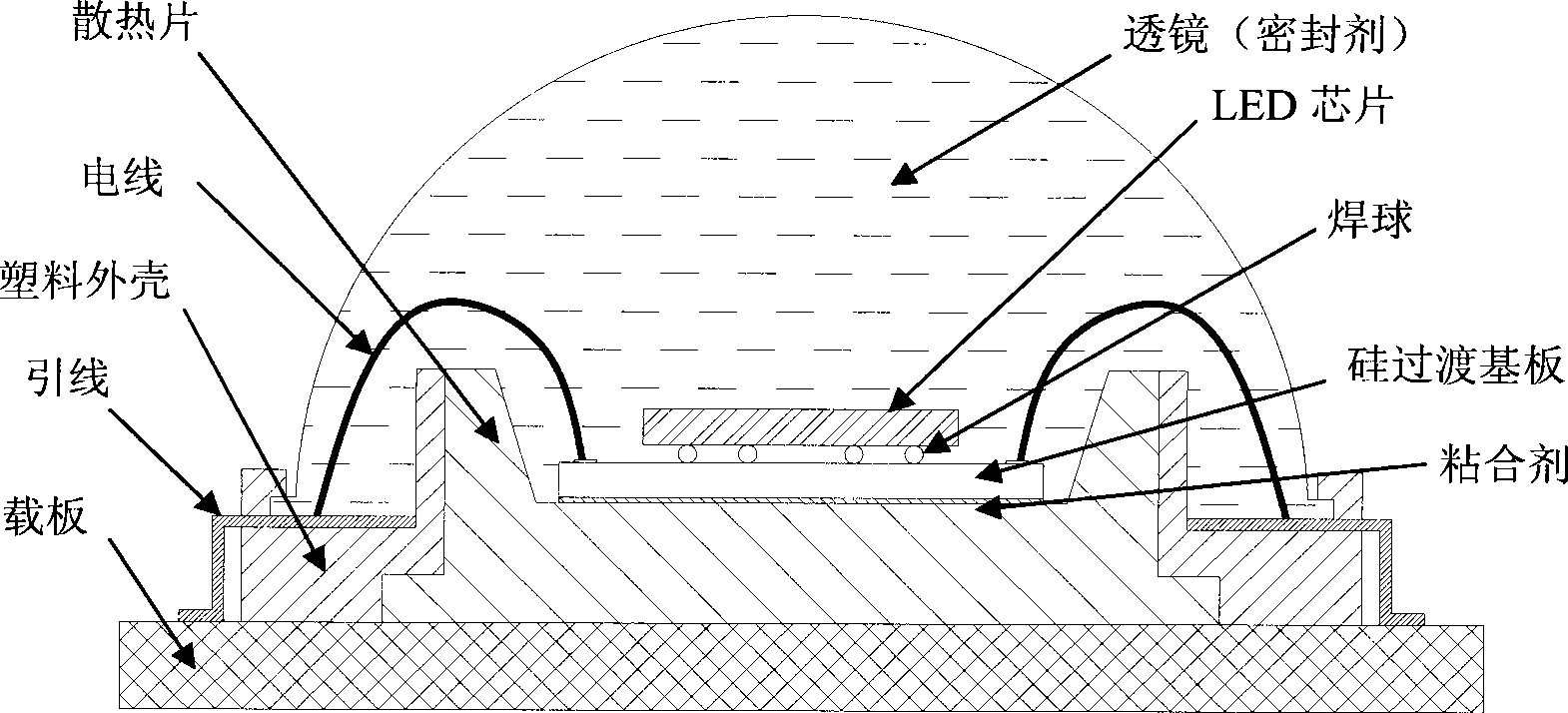

A technology of LED packaging and LED arrays, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., and can solve problems such as high cost, impossible high output, low-cost wafer-level packaging, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

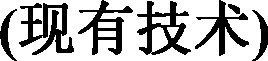

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Referring now to the drawings, wherein the same reference numerals in different drawings represent the same or similar parts. In addition, known functions and structures that are considered unnecessary to the essential point of the present invention are not described in detail.

[0018] figure 2 A cross-sectional view of an embodiment of the invention is shown. The device shown in the figure includes a wafer 201, patterned conductive layers 202a and 202b, pre-etched grooves 203a and 203b, LED chips 205a and 205b with solder balls 204a and 204b, and a sealed seal deposited by an injection needle 207. Agents 206a and 206b.

[0019] The method of the present invention starts with a wafer 201 . The detailed process is as follows:

[0020] Step 1: Etching groove structures 203a and 203b on the wafer 201 by deep reactive ion etching (DRIE)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com