Natural deicing fluid for freezing shrimp meat

An antifreeze and shrimp technology is applied in the field of antifreeze to prevent protein denaturation during the frozen storage process of frozen shrimp, which can solve the problems of sudden decrease in flavor, decrease in commercial value, and loss of umami, and achieve reduced water loss and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The invention will be further described below in conjunction with the description, but the scope of protection required by the present invention is not limited to the scope described in the embodiments.

[0008] 1 Materials and methods

[0009] 1.1 Processing of shrimp

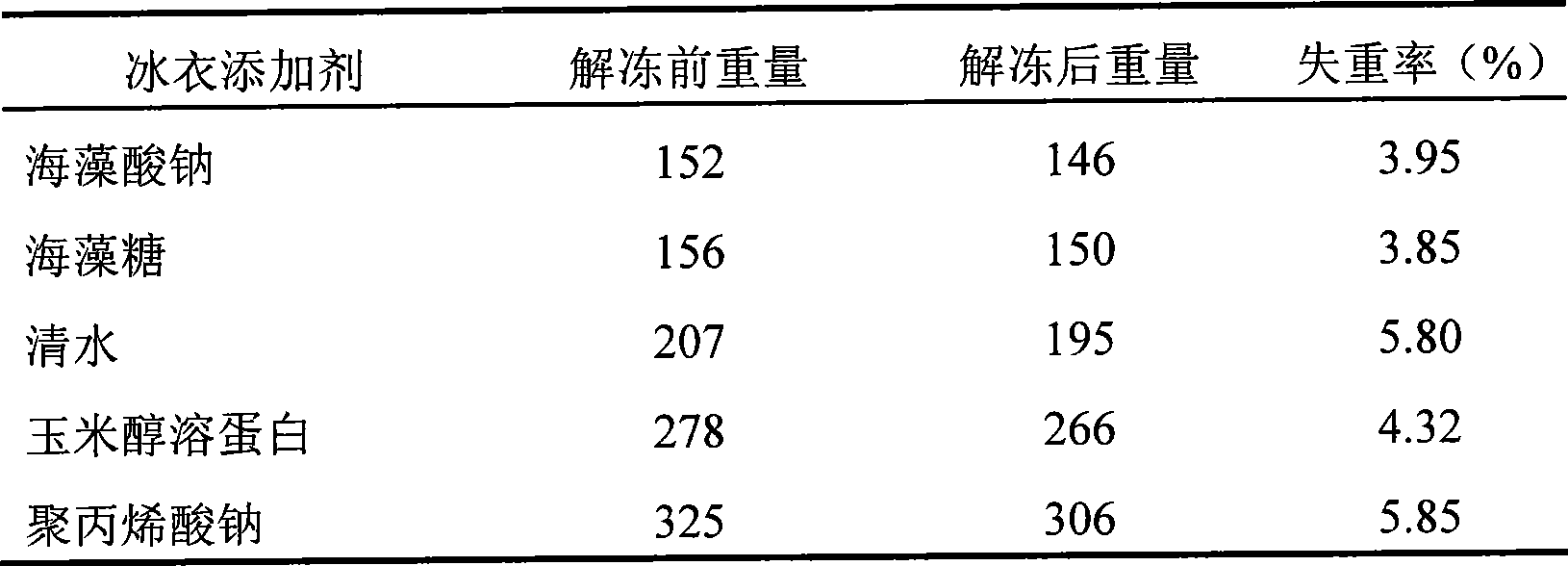

[0010] After peeling the shrimps, freeze them to -18°C, then immerse the shrimps in the ice solution with 0.5%-2% sodium alginate antifreeze, take them out quickly after 3-4min, pack them, and put them in the freezer at -18°C .

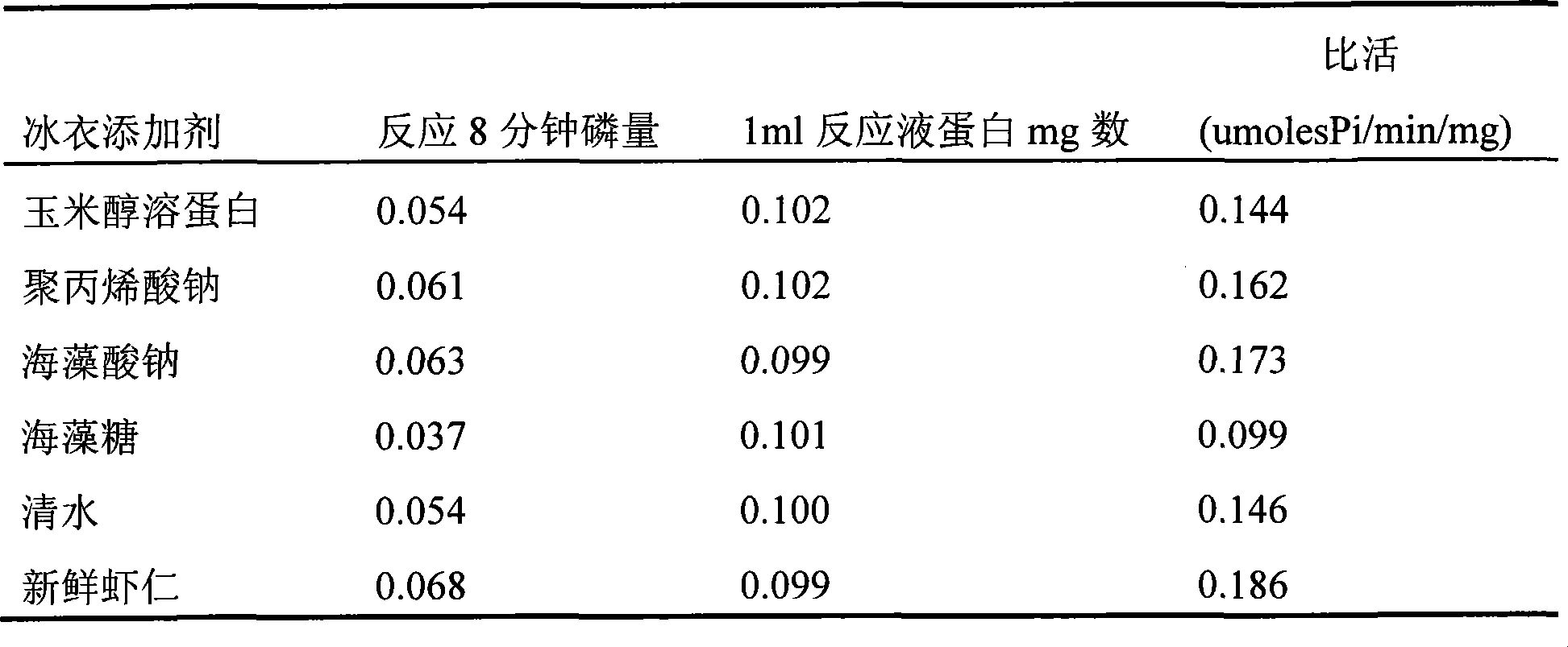

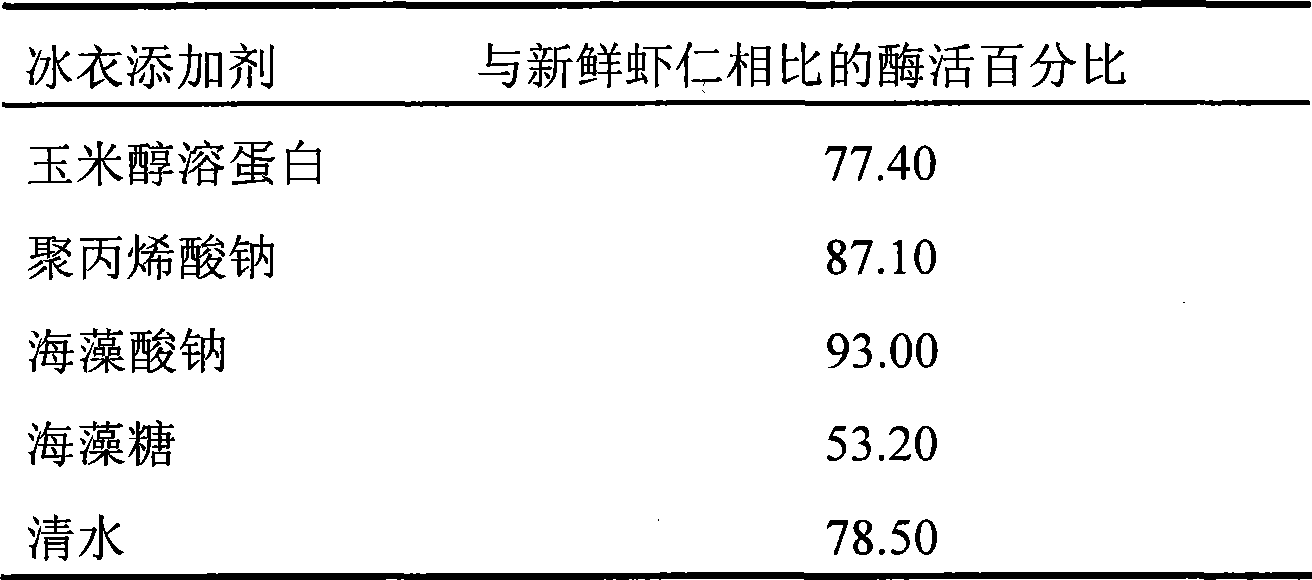

[0011] 1.2 Determination of ATPase in different ice-coated frozen shrimp

[0012] 1.2.1 Experimental principle

[0013] Actomyosin and myosin ATPase are easily affected by calcium ions, magnesium ions, EDTA, PCMB, ionic strength and pH. Therefore, choosing stringent conditions to measure the activity of ATPase can reflect the specific properties of the protein. Actomyosin and myosin, which make up shrimp muscle protein, cut off the phosphate group at the end of ATP to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com