System and method for manufacturing flocking wall hangings

A manufacturing system and flocking technology, applied to the surface coating liquid device, liquid spraying equipment, surface pretreatment, etc., can solve the problems of easy deviation of the end surface, deviation of the base fabric, and difficult correction, and achieve the pattern Clear and complete, improve the effect of flocking fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (Example 1, the manufacturing system of flocking wall covering)

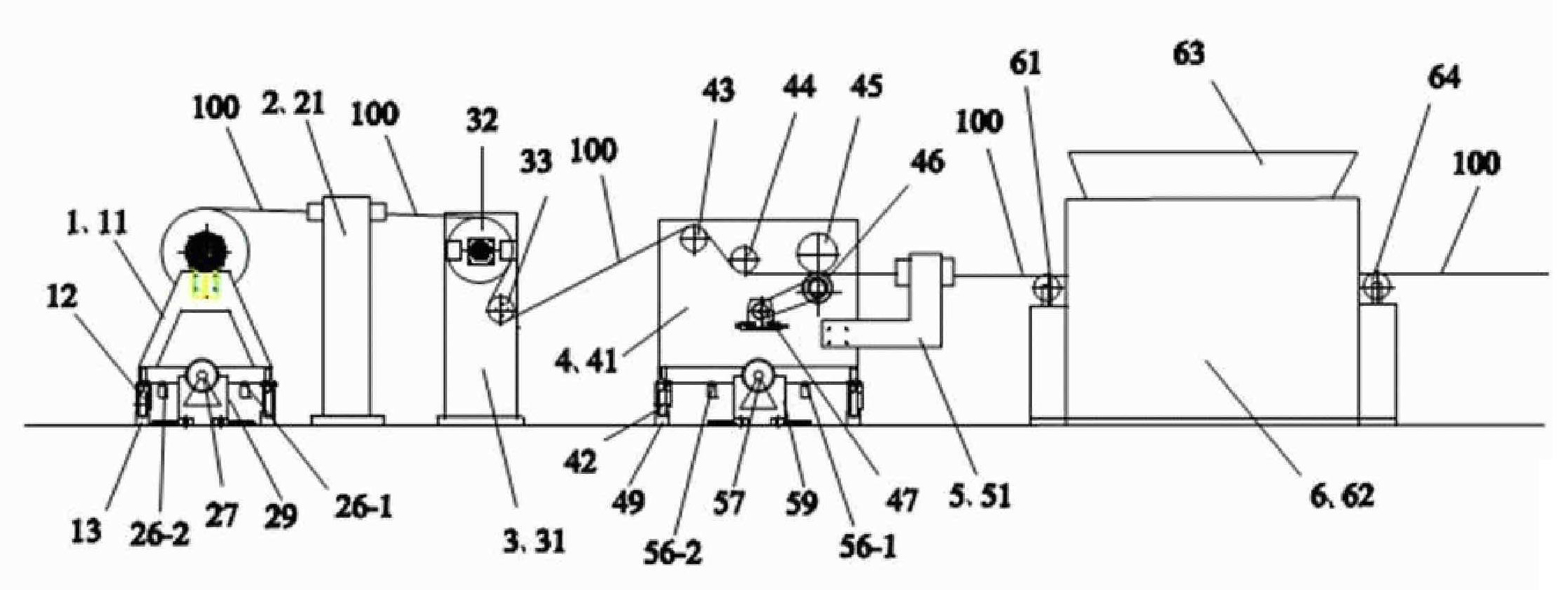

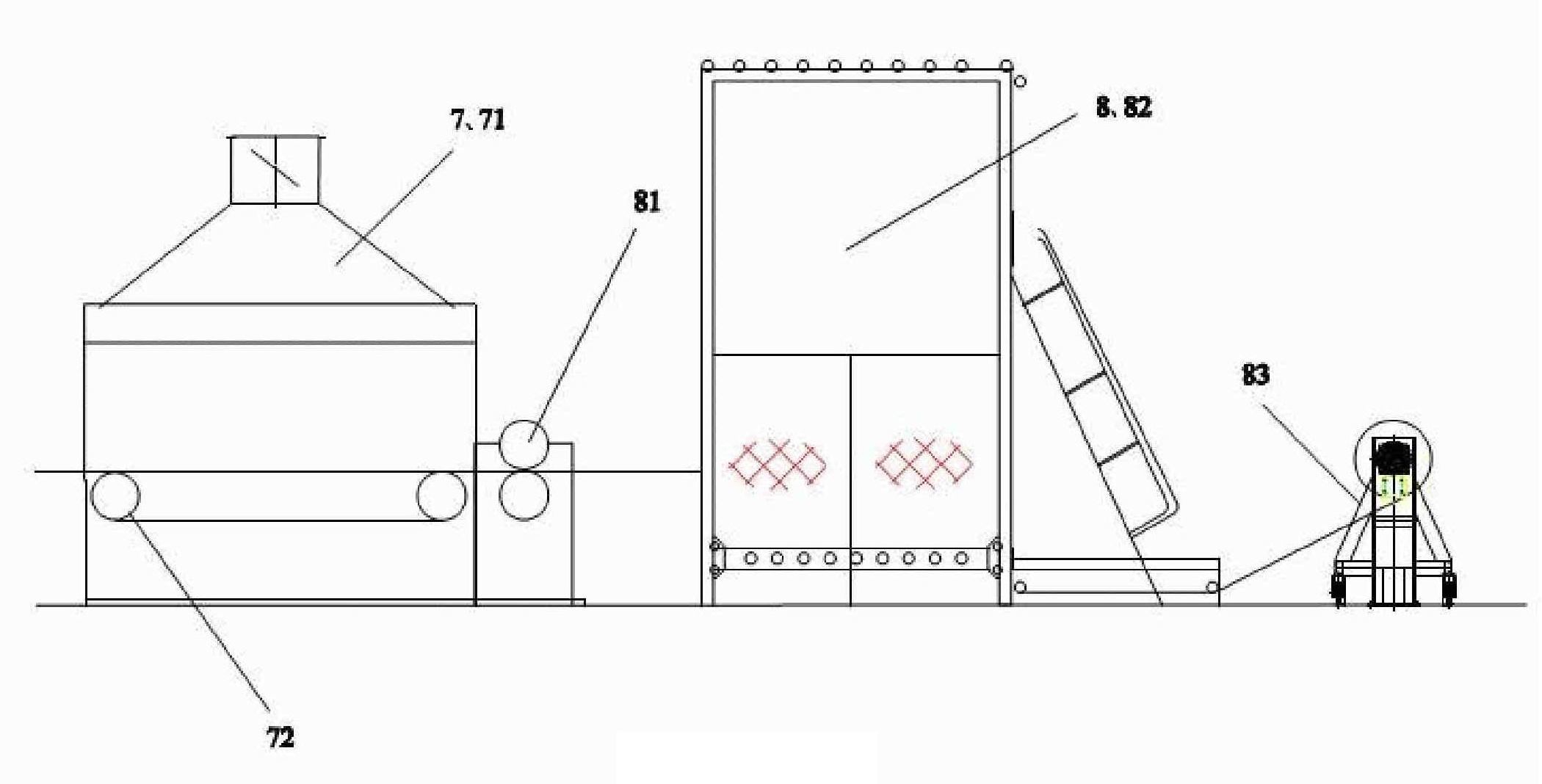

[0043] See figure 1 with figure 2 The system for manufacturing flocking wall coverings in this embodiment includes an unwinding device 1, an unwinding deviation correction device 2, a guide roller device 3, a cylinder gluing machine 4, a gluing and deviation correction device 5, an electrostatic flocking device 6, Oven 7, winding device 8 and motor synchronous control circuit.

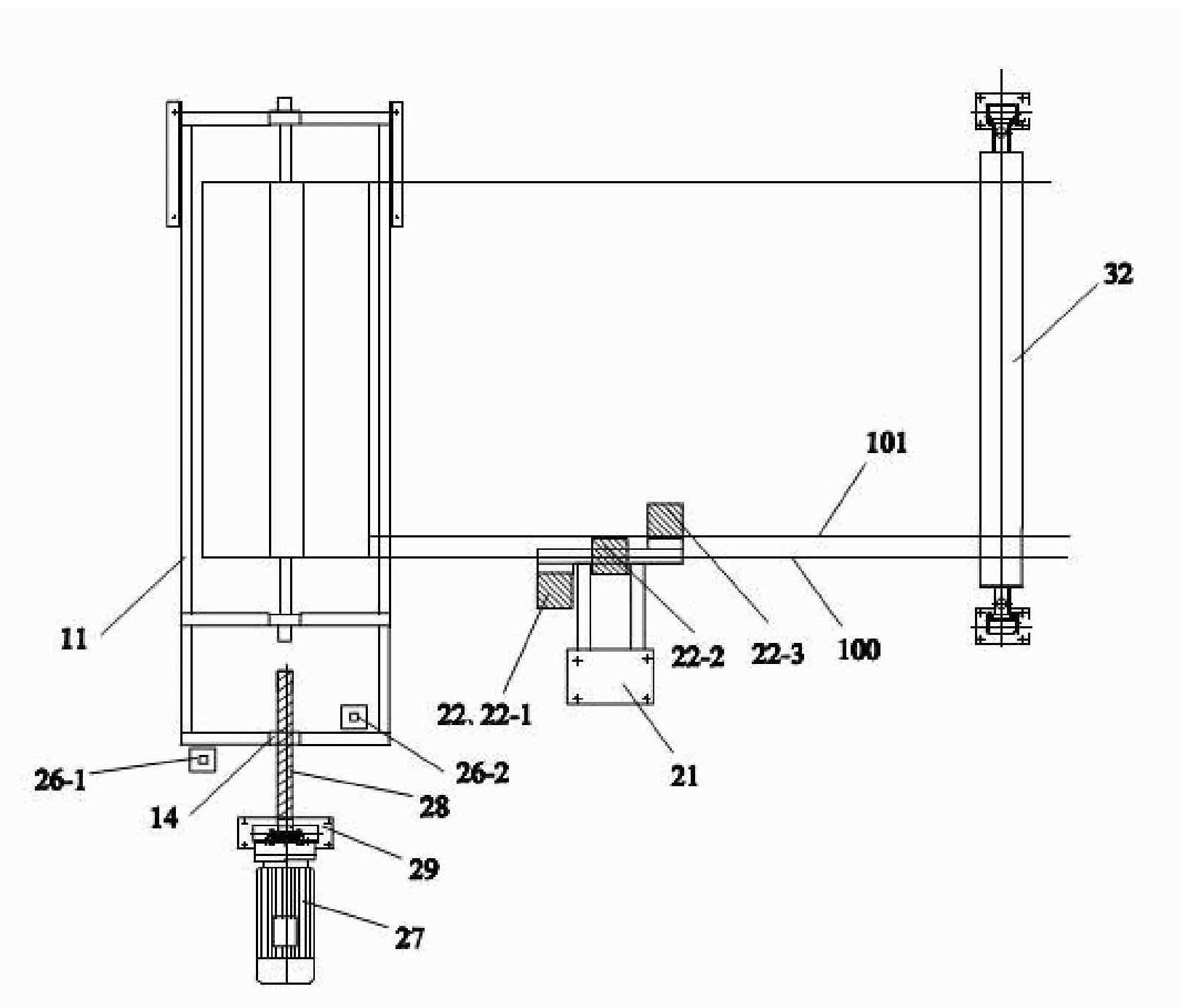

[0044] See figure 1 and image 3 , The unwinding device 1 includes an unwinding frame 11 , four rollers 12 , two guide rails 13 and a nut block 14 . Unwinding frame 11 is connected with 4 rollers 12 rotations by its roller seat. 4 rollers 12 are located in two by two on the guide rails 13 fixed on the ground, so that the unwinding frame 11 moves left and right along with the rolling of the rollers 12 on the guide rails. The nut block 14 is fixed on the unwinding stand 11.

[0045] See figure 1 , The guide roller device 3 ...

Embodiment 2

[0081] (embodiment 2, the manufacture method of flocking wall covering)

[0082] The manufacturing method of the flocked wall covering of the present embodiment is obtained from Embodiment 1 by the manufacturing system adopted. The specific method is as follows:

[0083] The glass fiber base cloth used has a thickness of 0.4 mm, and one edge of the glass fiber base cloth 100 is inlaid with a color line 101 as a color code. The cloth end of glass fiber base cloth 100 is sewn together with the guide cloth that is arranged on the manufacturing system of the flocking wall cloth from unwinding device 1 to winding device 8, and then the reel of glass fiber base cloth 100 is placed on On the unwinding frame 11 of the unwinding device 1, start the motor of the manufacturing system and apply a pulling force to the glass fiber base cloth 100 through the guide cloth, so that the glass fiber base cloth 100 that is arranged on the unwinding frame 11 of the unwinding device 1 The reel is ...

Embodiment 3~ Embodiment 6

[0101] (Example 3-Example 6, the manufacturing method of flocking wall covering)

[0102] The preparation method of each embodiment is basically the same as that of Example 2, and the differences are shown in Table 1.

[0103] Table 1

[0104]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com