Method for coproduction of bleaching powder and active carbon as well as chlorine-containing compound from carbide slag

A chlorine compound and carbide slag technology, applied in the direction of hypochlorous acid and hypochlorite, can solve the problems of less production, low production efficiency, and immature technology, so as to promote the development of enterprises and increase the total production value , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

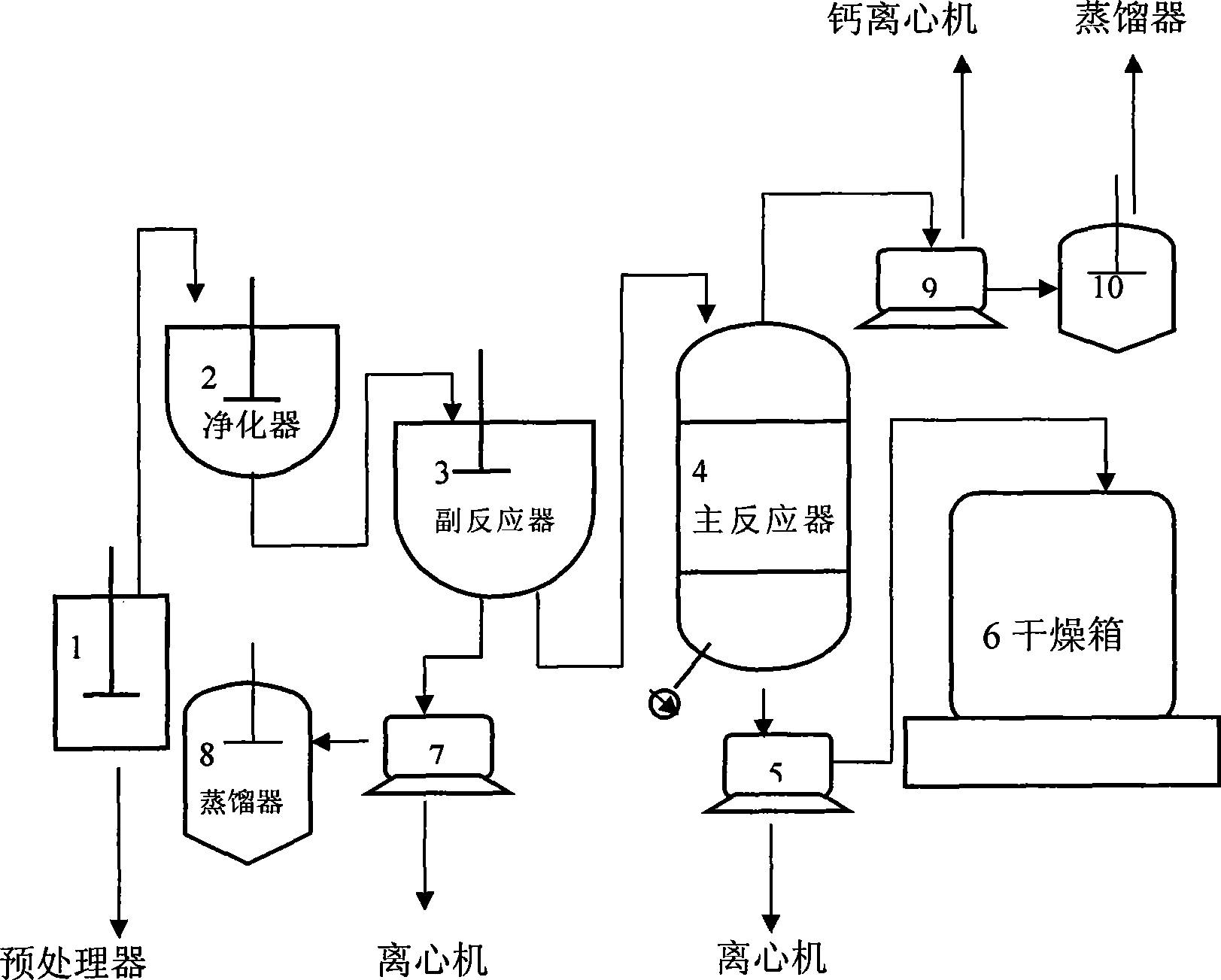

Method used

Image

Examples

Embodiment 1

[0025] 200kg of calcium carbide slag (calcium hydroxide content is 85%; dry material) and 600kg of water are injected into preprocessor 1 with a stirring device and stirred to form a uniform emulsion, and naturally settle for 30s to form suspended calcium hydroxide emulsion liquid; calcium hydroxide emulsion and hydrochloric acid are injected into the purifier 2 according to the pure substance quality 1:0.8, stirred for 10 minutes to make the substance completely react, and after the reaction solution is filtered, calcium chloride filtrate and filter cake are formed; calcium chloride filtrate and the sodium hydroxide generated by electrolysis is injected into the sub-reactor 3 according to the pure substance quality 1:0.6 and stirred to generate high-purity calcium hydroxide and relatively pure sodium chloride solution, and the sodium chloride solution is produced by centrifuge 7 and distiller 8 Get industrial salt containing sodium chloride 186.57kg, high-purity calcium hydrox...

Embodiment 2

[0027] The process flow is as in Example 1, 200kg calcium hydroxide slag (calcium hydroxide content is 85%; dry material) and 1200kg water, natural sedimentation for 50s, calcium hydroxide emulsion and hydrochloric acid according to the pure substance quality 1:1.2, stir for 10 minutes , calcium chloride filtrate and sodium hydroxide generated by electrolysis according to the pure substance quality 1:1.1, the industrial salt containing sodium chloride 268.78kg, high-purity calcium hydroxide and chlorine gas pure substance quality 1:1.1, the bleaching powder finished product 154.31kg, filter cake reacts with the hydrochloric acid solution of concentration 10%, both obtained high-quality gac product 12kg, makes 93.5kg calcium chloride dihydrate.

Embodiment 3

[0029] The process flow is as in Example 1, 200kg of calcium carbide slag (calcium hydroxide content is 85%; dry material) and 800kg of water, natural sedimentation for 20s, calcium hydroxide emulsion and hydrochloric acid according to the pure substance quality 1:0.6, stir for 10 minutes , calcium chloride filtrate and sodium hydroxide generated by electrolysis according to the pure substance quality 1:0.4, the industrial salt containing sodium chloride 93.27kg, high-purity calcium hydroxide and chlorine gas pure substance quality 1:0.4, ready-made bleaching powder refined product 33.74kg, filter cake reacts with the hydrochloric acid solution of concentration 10%, both obtained high-quality gac product 12kg, makes 20.44kg calcium chloride dihydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com