Biomass gasification equipment and process

A biomass and equipment technology, which is applied in the petroleum industry, special dry distillation, coke oven, etc., can solve the problems of reduced working efficiency of air compressors, reduced gasification efficiency, and high specific gravity, so as to achieve stable and reliable gasification process, prevent Corrosion, structurally sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

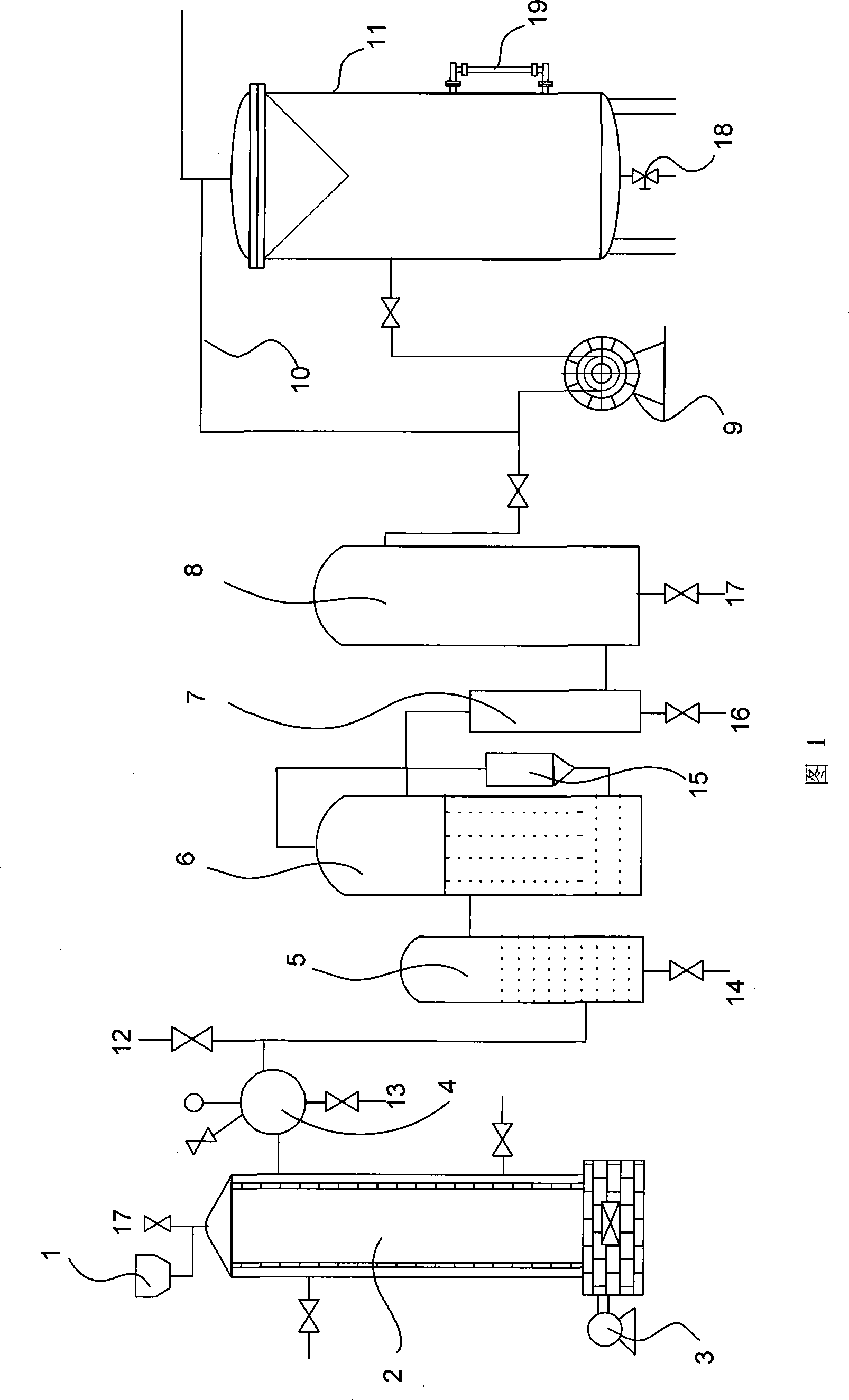

[0047] Now in conjunction with accompanying drawing, the present invention is described in further detail:

[0048]The biomass gasification equipment, as shown in Figure 1, includes a gas generator 2 with a furnace body height of 1500mm and a diameter of 1200mm, an anoxic chamber in the furnace with a height of 1200mm and an inner diameter of 800mm; two gas buffers 4, 7, They are respectively placed on the outlet pipe of the gas generator 2 and the outlet pipe of the water spray filter 6; one water filter 5, one spray tank 6, one dry filter 8, one 1.5KW blower 3, and a water ring compressor 9 and a gas-water separator 11 each, the water ring compressor is equipped with a pressure balance pipe 10, one end of the pressure balance pipe 10 is connected to the gas pipeline at the inlet end of the water ring compressor 9, and the other end is connected to the gas-water separator 11 The gas pipeline at the gas outlet; the gas-water separator 11 is provided with a drain valve 18 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com