High temperature corrosion inhibitor for atmospheric vacuum distillation apparatus

A technology of high-temperature corrosion inhibitor and atmospheric and vacuum distillation, which is applied in the field of high-temperature corrosion inhibitor, can solve the problems of poor corrosion inhibition rate, peeling of equipment pipelines, corrosion filling system, etc., and achieve the protection of equipment and process pipelines , Inhibit corrosion, high corrosion inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

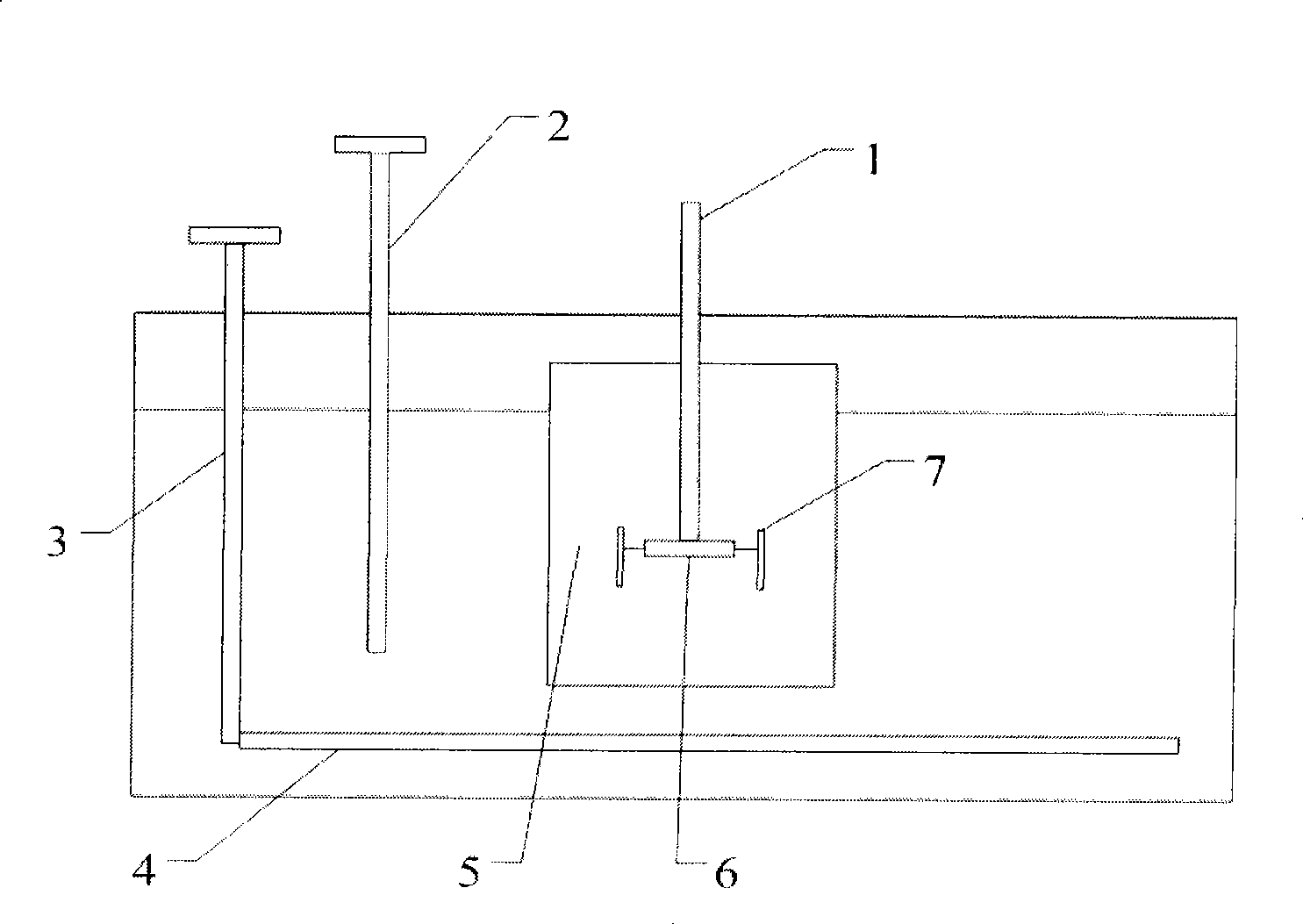

Image

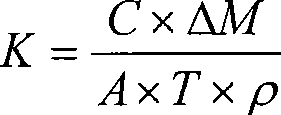

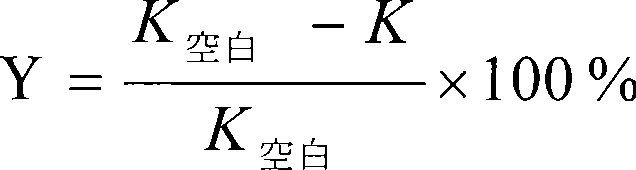

Examples

Embodiment 1

[0018] Example 1: 30% oleic acid amide, 15% dodecyl dimethyl tertiary amine, 20% O, O-diisopropyl ammonium thiophosphate, 35% C10 heavy aromatics, mixed uniformly to form high temperature corrosion inhibition agent a

Embodiment 2

[0019] Example 2: 20% tall oil fatty acid amide, 5% tetraethylenepentamine, 10% nonylphenol sulfonic acid, 30% dimethyl dithiophosphate, 35% C10 heavy aromatics, mixed evenly to form a high-temperature corrosion inhibitor b

Embodiment 3

[0020] Embodiment 3: coconut oil fatty acid amide 10%, dodecyl primary amine 10%, dodecylphenol sulfonic acid 10%, monoethyl trithiophosphate 10%, C10 heavy aromatic hydrocarbon 60%, mix uniformly and form High temperature corrosion inhibitor c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com