High precision microscopic fatigue tester

A fatigue testing machine, high-precision technology, applied in the field of testing machines, to achieve the effect of low system drive current and power consumption, low maintenance and maintenance requirements, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A specific embodiment of a high-precision microscopic fatigue testing machine of the present invention is provided below.

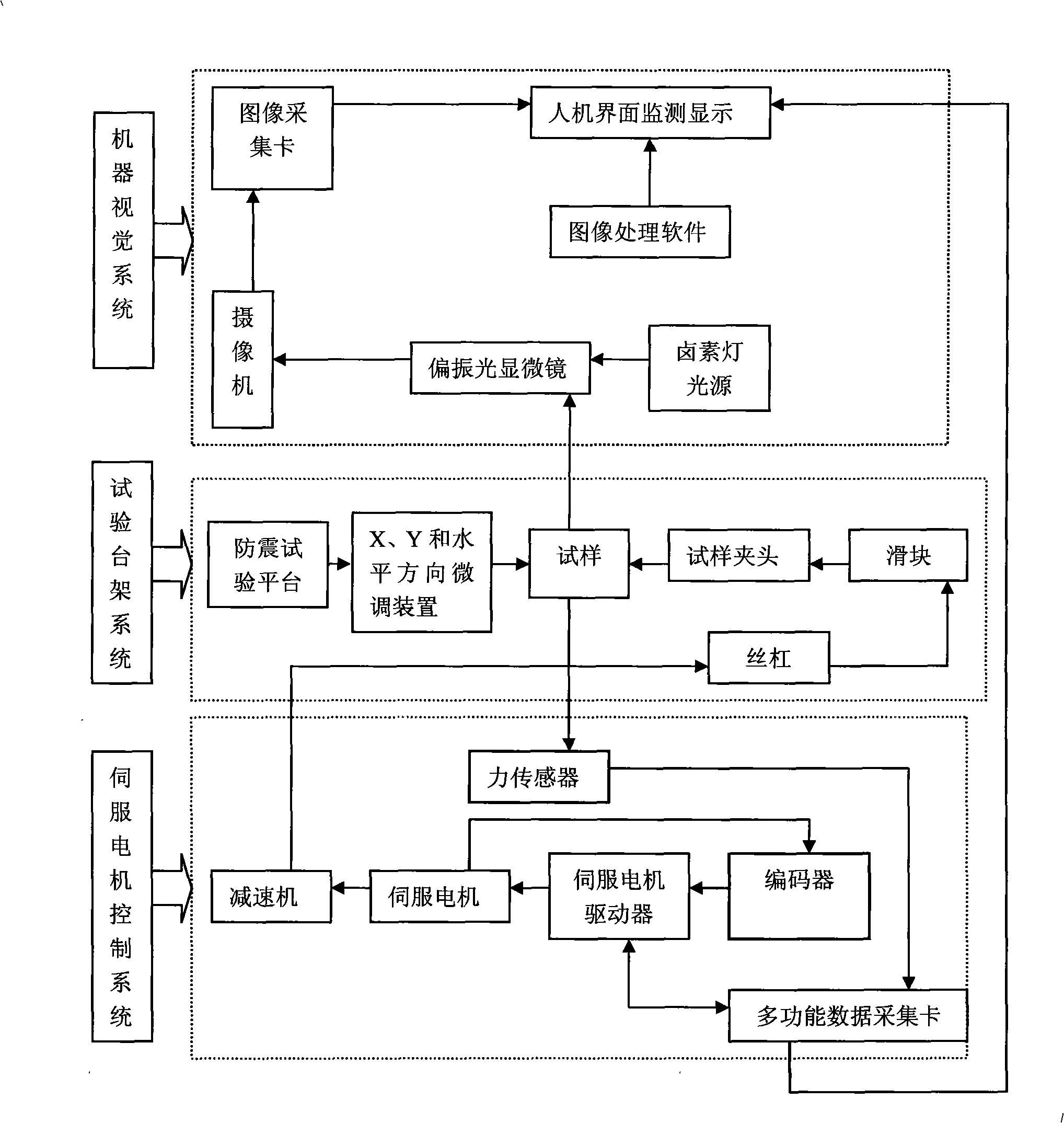

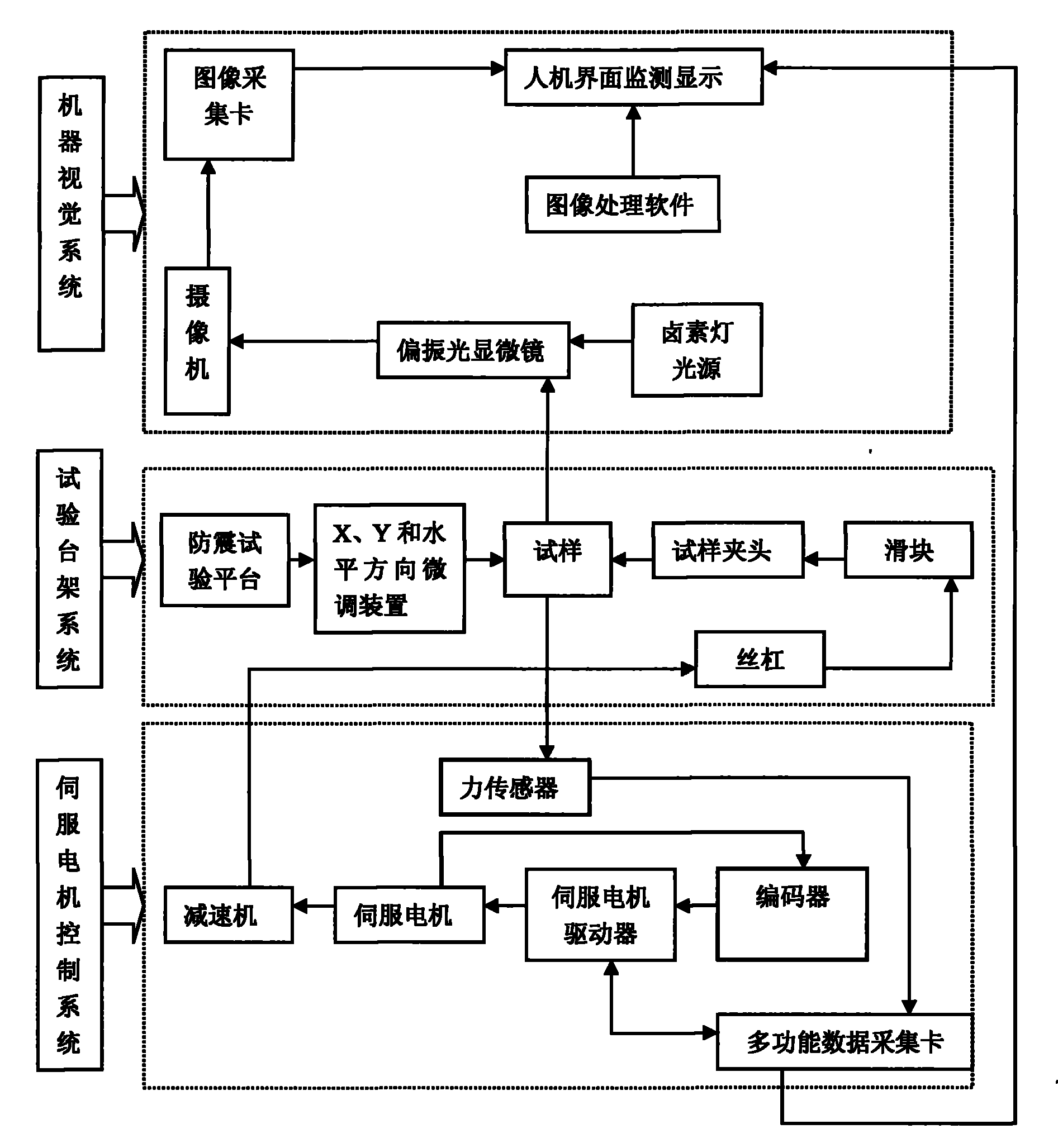

[0033] See figure 1 , a high-precision micro-fatigue testing machine, including a test bench system, a servo motor control system and a machine vision system; the servo motor control system is connected to the servo motor driver 2 through a multifunctional data acquisition card 11, and the servo motor driver 2 drives the servo The motor 1 and the servo motor 1 are connected to the reducer, the reducer drives the lead screw of the test bench system, and the lead screw drives the fixture to stretch the sample to realize various fatigue loading modes, microscopic changes appear on the sample surface, and through the machine vision system After the polarization microscope is enlarged, the video image is collected by the camera, displayed on the computer through the image acquisition card, and then the size of the microscopic crack is measured by the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com