Method for implementing low pump power density and continuous light pump laser

A technology of power density and laser, applied in the field of laser, can solve the problems of high dispersion and incompatibility, and achieve the effect of reducing the laser threshold, improving the pumping efficiency, and reducing the pumping power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

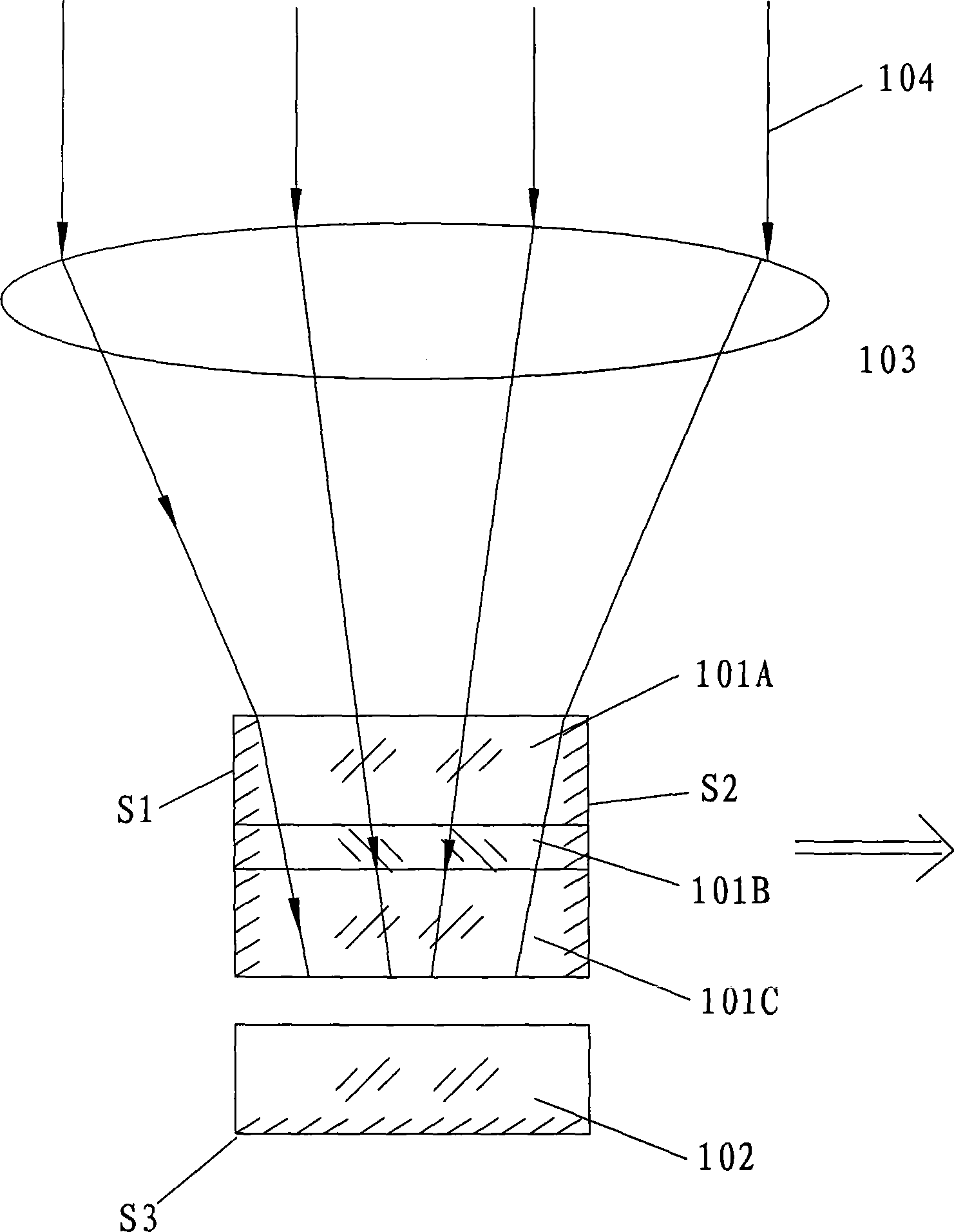

[0043] Such as Figure 1a As shown, 101A, 101B, and 101C constitute a composite thin gain medium microchip, wherein 101B is a laser gain medium sheet, and 101A and 101C can be ordinary and laser gain medium matrix materials or their optical materials, and can also produce up-conversion or conversion fluorescence. material, cavity mirror S1 and cavity mirror S2 constitute the laser cavity surface. 102 is an optical material that can generate up-conversion or down-conversion fluorescence, S3 is a broadband reflection film or a reflection surface, 103 is a focusing lens, and 104 is a pumping beam.

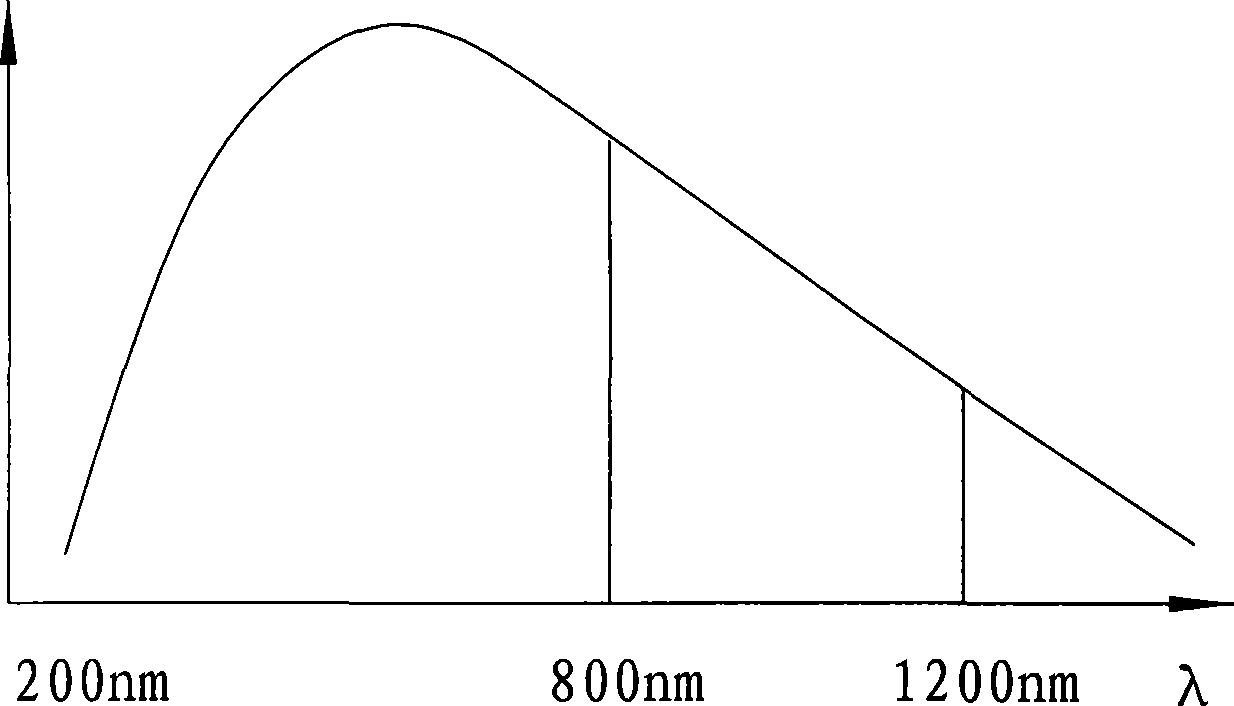

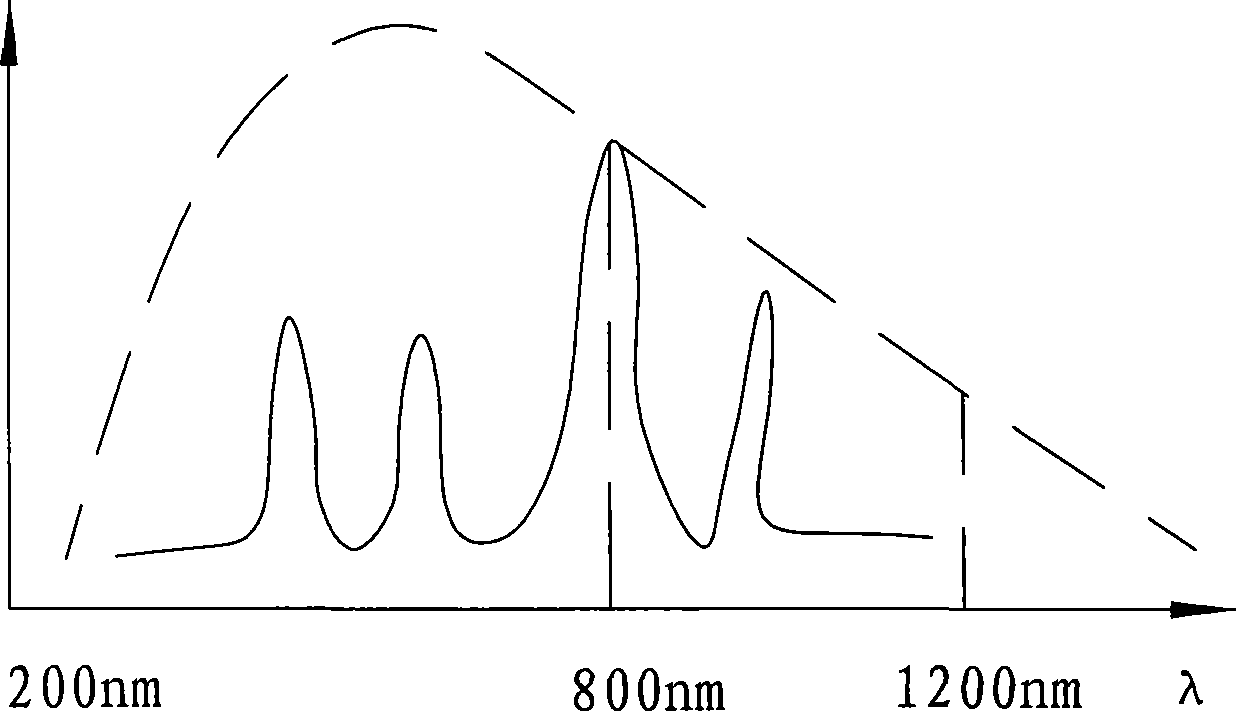

[0044] Principle of the present invention is: because surface solar energy density is low, its spectrum is continuous spectrum, and band is wider, as Figure 1b A graph of the solar spectrum is shown. Most of the media used to generate laser gain, especial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com