Perovskite thin film packaging method for water environment and application of perovskite thin film packaging method

A technology of thin film encapsulation and perovskite, which is applied in the fields of nanomaterials and laser optics, can solve the problems of complex process and expensive, and achieve the effect of low laser threshold, strong emission intensity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

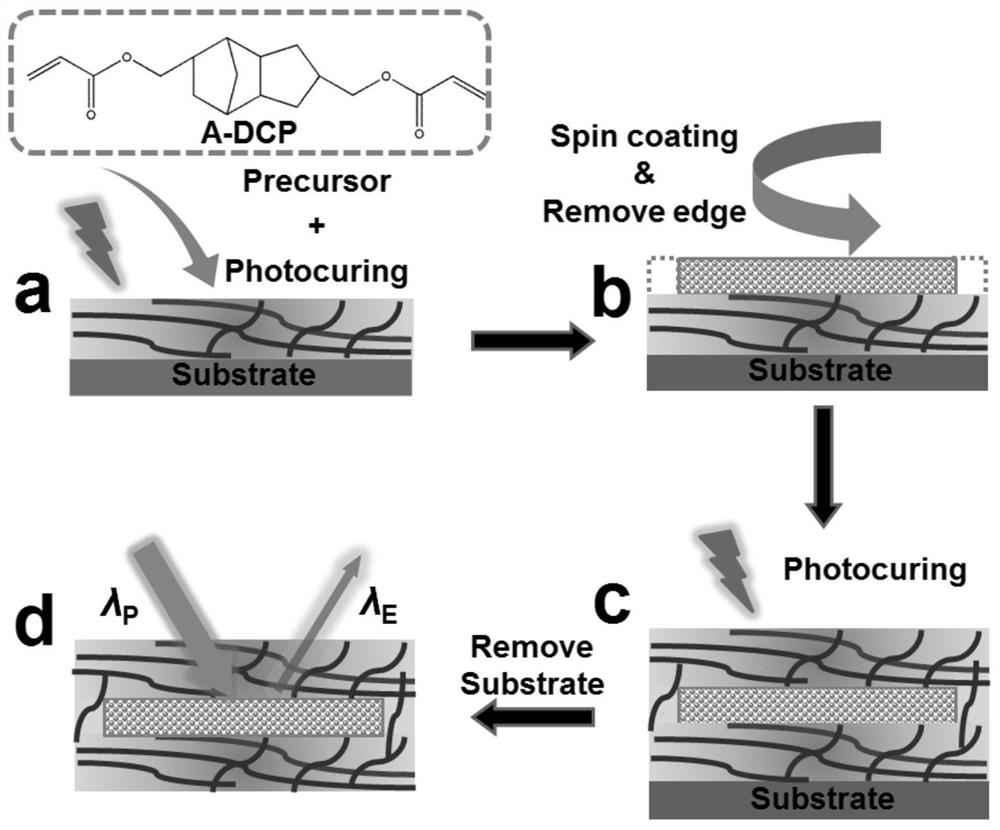

[0028] figure 1 It is a schematic diagram of a method for encapsulating a perovskite film by photopolymerization according to Embodiment 1 of the present invention. like figure 1 As shown, the steps of the method include:

[0029] (1) In a dark room environment, use a pipette to drop 100 μl of tricyclodecanedimethanol diacrylic acid monomer onto a 1.5 cm×1.5 cm quartz plate, and cover it with an identical quartz plate with a spacing of 500 μm.

[0030] (2) Irradiate with a UV LED lamp in a dark room environment, and the lamp power is set to 50μW / cm 2, Acrylic acid undergoes photopolymerization, and after 10 minutes of irradiation to form a film, the acrylic base film obtained from the upper glass slide is peeled off to form a solid polymer layer 1 with a thickness of 400 μm;

[0031] (3) Treat the surface of the obtained acrylic substrate with an oxygen plasma cleaner.

[0032] (4) In a nitrogen glove box, mix 30 μl of MABr and PbBr with DFM as solvent 2 Spin-coating of p...

Embodiment 2

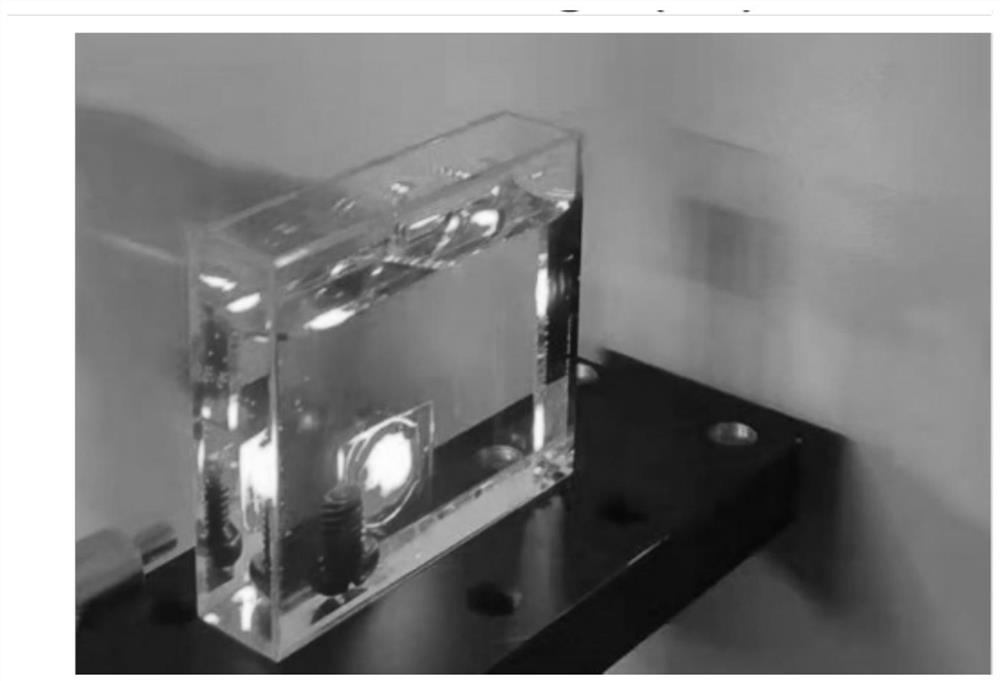

[0036] figure 2 A physical image of a sample working in water using acrylic-encapsulated perovskite films.

[0037] The liquid in the cuvette is deionized water, and the middle is the acrylic-encapsulated MAPbBr under optical pumping 3 film.

Embodiment 3

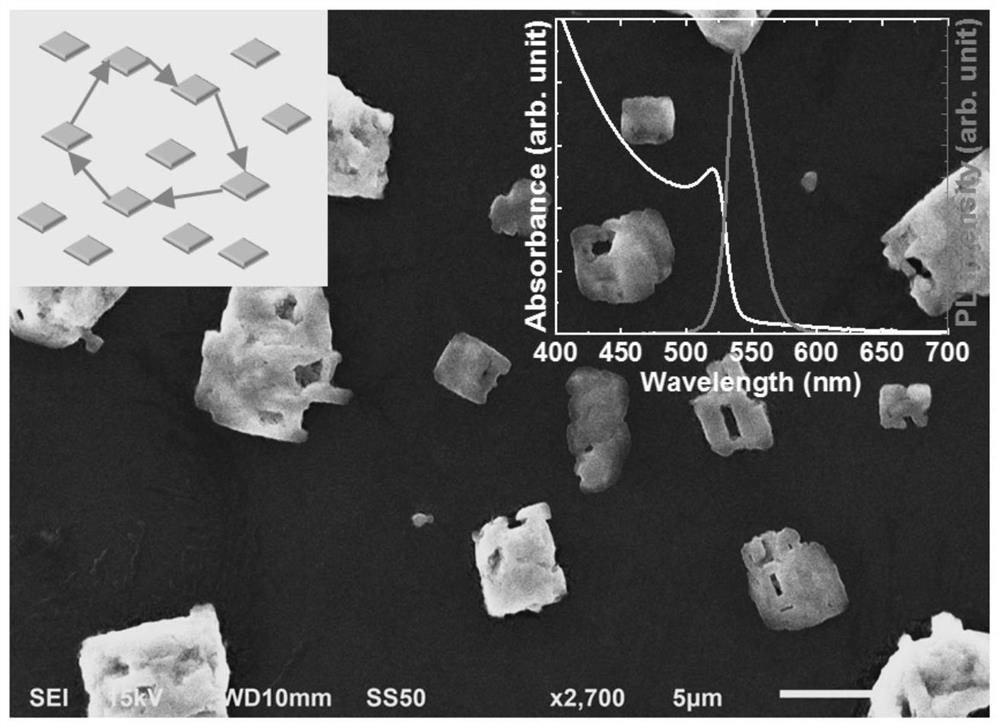

[0039] image 3 for MAPbBr prepared on acrylic substrates 3 Scanning electron microscope pictures of thin films. The successful formation of crystalline clusters, encapsulated MAPbBr, can be observed under the microscope 3 The thin film crystals are of good quality. image 3 The data in the middle are the absorption spectrum and PL spectrum of the perovskite film, and the surface has good optical properties.

[0040] The absorption spectrum was measured by a xenon lamp and a USB4000 fiber optic spectrometer, and the PL spectrum was excited by a 400 nm femtosecond pulsed laser and measured by a USB4000 fiber optic spectrometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com