Method for recovering tail gas from trichlorosilane production and special equipment thereof

A technology of trichlorosilane and recovery methods, which is applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as hydrogen film corrosion, hydrogen film blockage, production cannot continue normal operation, etc., and achieve a practical recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

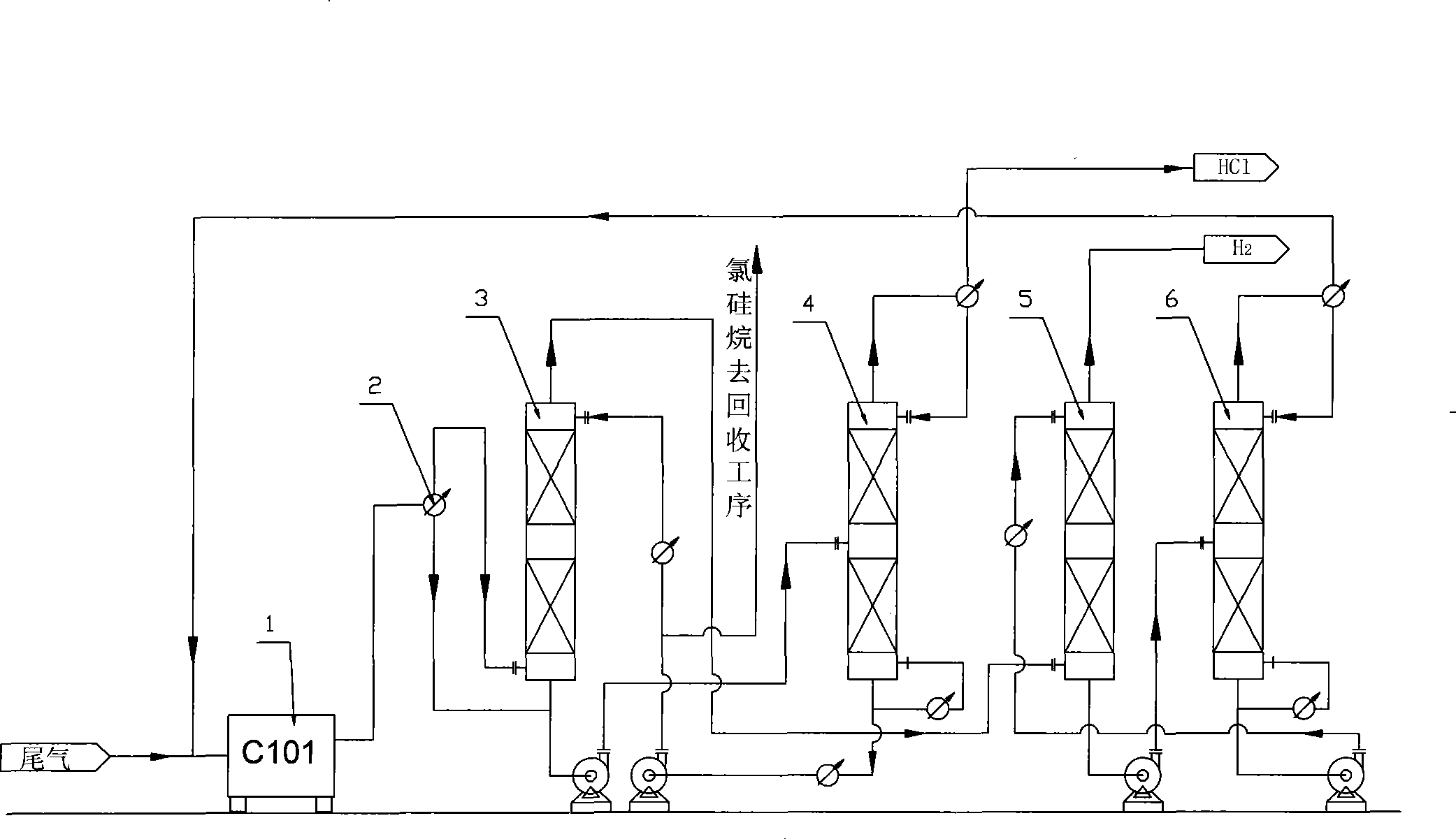

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The recovery method of trichlorosilane production tail gas of the present invention, the method comprises the following steps:

[0026] 1. The tail gas produced by the synthesis of trichlorosilane is condensed after being pressurized by a pump, the pressure is 0.6MPa, and the condensation temperature is -40°C, so that most of the chlorosilanes in the tail gas are condensed to form a condensate.

[0027] 2. The non-condensable gas enters the absorption tower after being pressurized. The temperature of the absorption tower is controlled at -40°C and the pressure is 0.6MPa. In the absorption tower, chlorosilane is used to absorb hydrogen chloride to obtain a chlorosilane absorption liquid. Crude hydrogen gas comes out from the top of the absorption tower. Crude hydrogen enters the scrubber, the temperature of the scrubber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com