Tension linear drawing machine

A wire drawing machine, tension-type technology, applied in the field of tension-type linear wire drawing machine, can solve the problems of uneven and unstable wire force, affecting the filling effect of wire core powder, radial shrinkage or fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

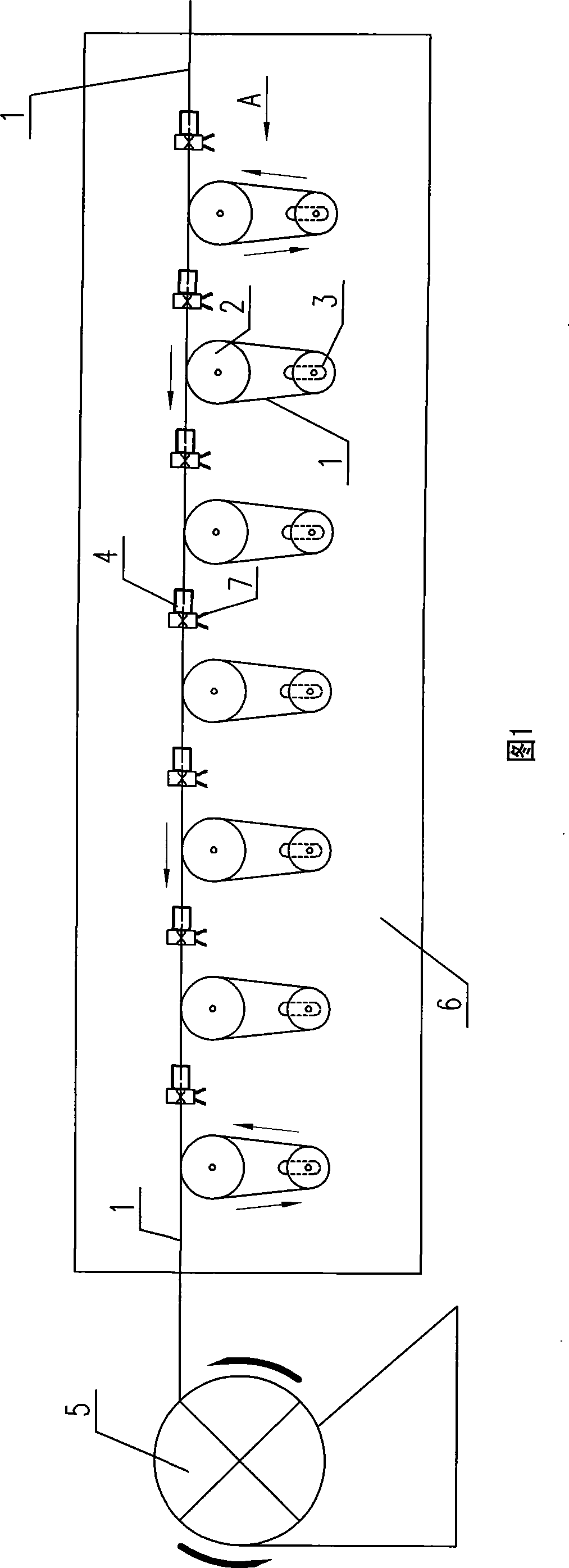

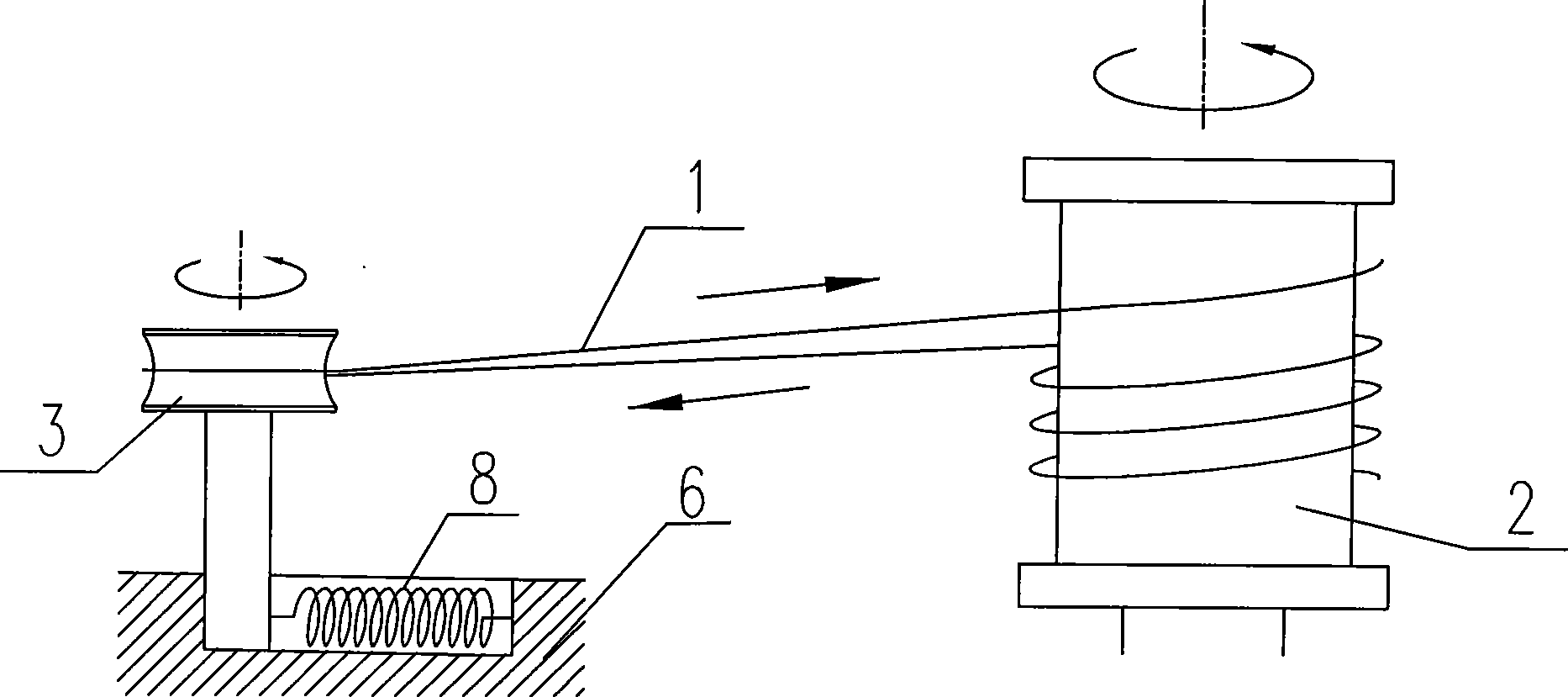

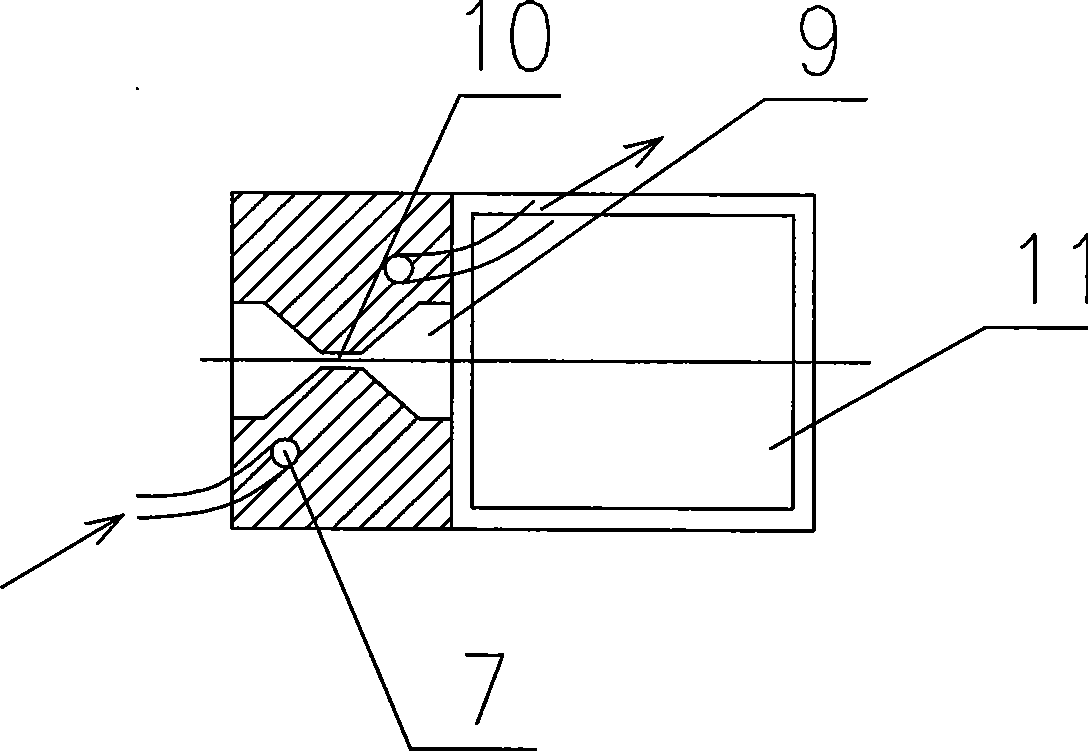

[0014] Figure 1, image 3 As shown, this embodiment includes a workbench 6, a wire take-up machine 5, a number of wire drawing dies 4, a number of electric speed-adjustable cone reels 2 and a number of tension regulators 3, wherein each of the wire drawing dies is provided with There is a reducing hole 10, the wire inlet and outlet at both ends of the reducing hole are tapered ports 9, and a solid lubricating container 11 is provided at the wire inlet end of each wire drawing die. At the same time, in the wire drawing die Cooling pipe 7 is set on the mold body (such as image 3 Shown), the two ends of the cooling pipe are connected with the automatic circulation cooling system (not shown in the figure).

[0015] As shown in Figure 1, each drawing die 4 is arranged and fixed on the worktable 6 in sequence based on the center line of the reducing hole 10, and the diameter of the reducing hole of each drawing die is gradually reduced. The drum 2 is arranged between the wire drawing die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com