Method for producing ductile cast iron by taking iron slag taken out by molten iron when pretreating slag skimming as material

A technology of molten iron pretreatment and ductile iron, applied in the field of metallurgy to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

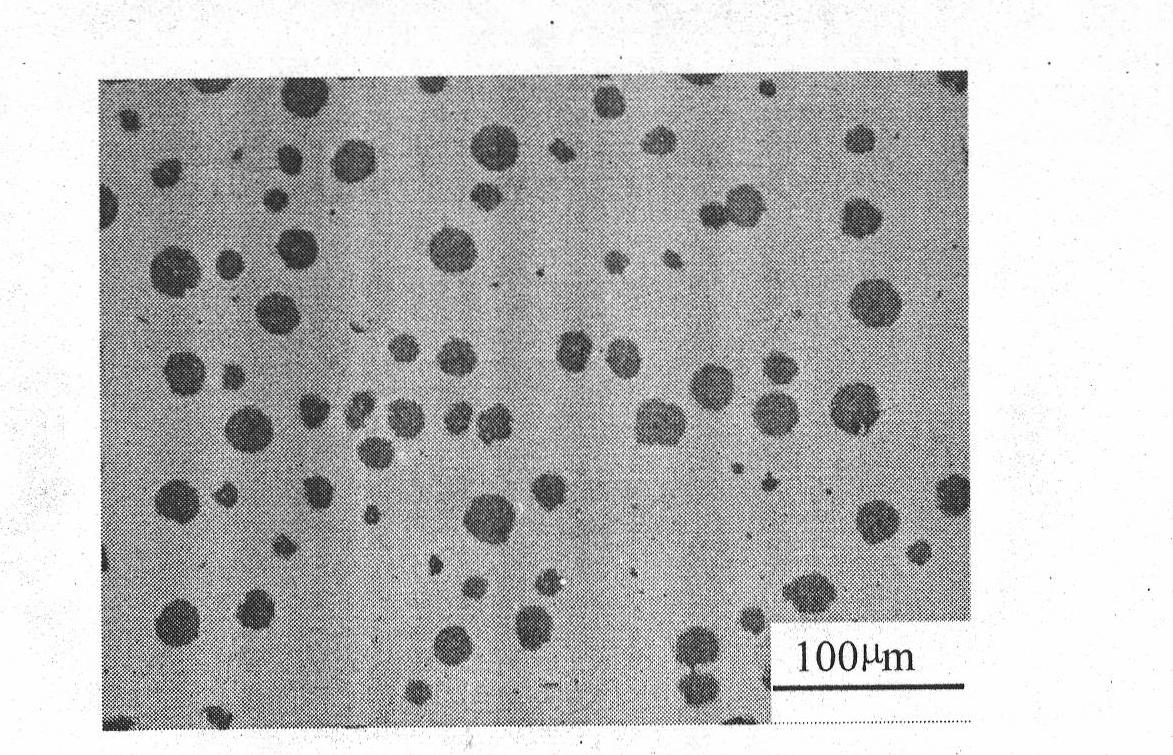

[0018] Use this method to produce 1t of ductile iron with the designation QT500-7. The melting equipment adopts 450kVA, 1.5t industrial frequency induction furnace. The iron slag is smelted in an induction furnace. The composition of the iron slag used is C: 3.5%, Si: 0.8%, Mn: 0.35%, S: 0.033%, P: 0.03%, Mg: 0.025%, and the balance For Fe. The melting temperature is 1550°C, and the melting time is 40 minutes. 15kgCaC 2 Put it into the bottom of the ladle with 17kg75SiFe at the same time and wait for the molten iron to rush in. After pouring into molten iron, inoculation and desulfurization treatment are carried out. The treatment temperature is 1430°C and the treatment time is 10 minutes. After the inoculation treatment, the wire feeding method is used for spheroidization treatment. The wire feeding equipment is a single-head wire feeding machine, the nodulizer is QRMg8RE3, the core wire diameter is 10mm, the wire quality is 169g / m, and the wire feeding speed is 100m / min ...

example 2

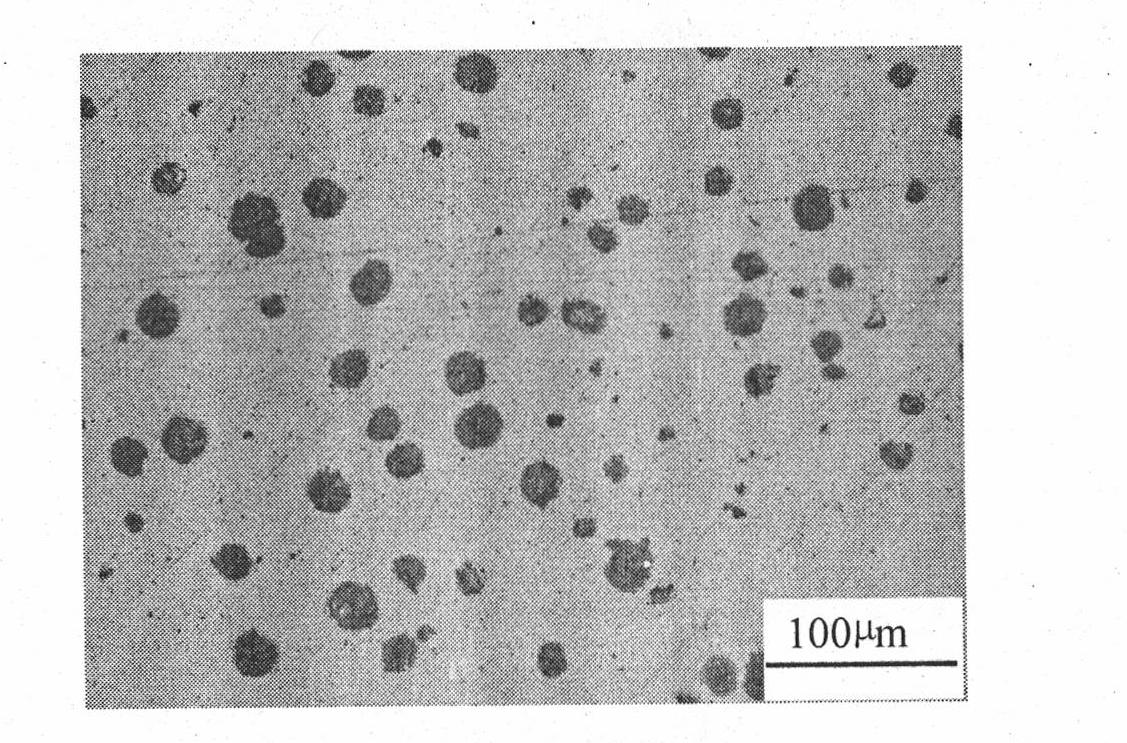

[0020] Use this method to produce 1t of ductile iron with the brand name QT400-15. The melting equipment adopts 450kVA, 1.5t industrial frequency induction furnace. The slag iron is smelted in an induction furnace, and the composition of the slag iron used is C: 2.8%, Si: 0.5%, Mn: 0.45%, S: 0.023%, P: 0.04%, Mg: 0.03%, and the balance For Fe. The melting temperature is 1530°C, and the melting time is 30 minutes. 12kgCaC 2 Put it and 25kg75SiFe into the bottom of the ladle at the same time and wait for the molten iron to rush in. After pouring into molten iron, inoculation and desulfurization treatment are carried out. The treatment temperature is 1400°C and the treatment time is 8 minutes. After the inoculation treatment, the wire feeding method is used for spheroidization treatment. The wire feeding equipment is a single-head wire feeding machine, the nodulizer is QRMg8RE3, the core wire diameter is 12mm, the wire quality is 172g / m, and the wire feeding speed is 120m / min...

example 3

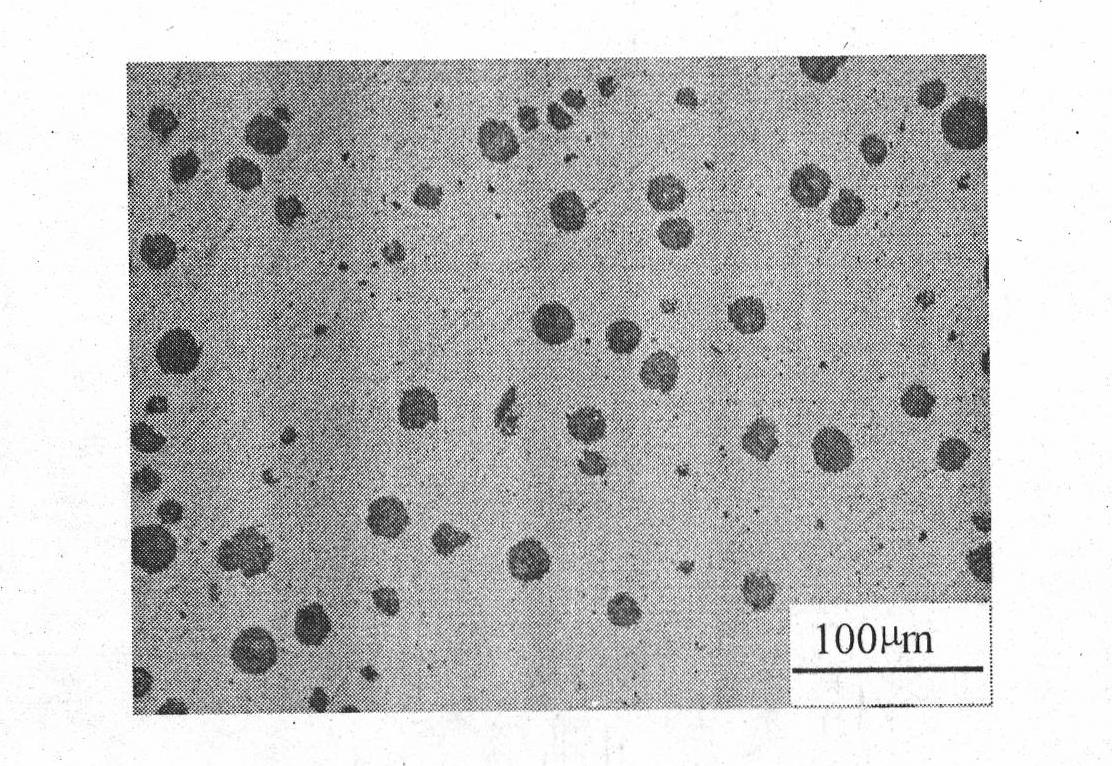

[0022] Use this method to produce 1t of ductile iron with the designation QT700-2. The melting equipment adopts 450kVA, 1.5t industrial frequency induction furnace. The iron slag is smelted in an induction furnace, and the composition of the iron slag used is C: 3.0%, Si: 0.9%, Mn: 0.5%, S: 0.019%, P: 0.03%, Mg: 0.022%, and the balance For Fe. The melting temperature is 1500°C, and the melting time is 40 minutes. 7kgCaC 2 Put it into the bottom of the ladle with 16kg75SiFe at the same time and wait for the molten iron to rush in. After pouring into molten iron, inoculation and desulfurization treatment are carried out. The treatment temperature is 1400°C and the treatment time is 15 minutes. After the inoculation treatment, wire feeding method is used for spheroidization treatment. The wire feeding equipment is a single-head wire feeding machine, the nodulizer is QRMg8RE3, the core wire diameter is 13mm, the wire quality is 230g / m, and the wire feeding speed is 100m / min ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com