Brine battery grade lithium carbonate preparation method

A brine battery and lithium carbonate technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of low production cost, easy industrial production, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

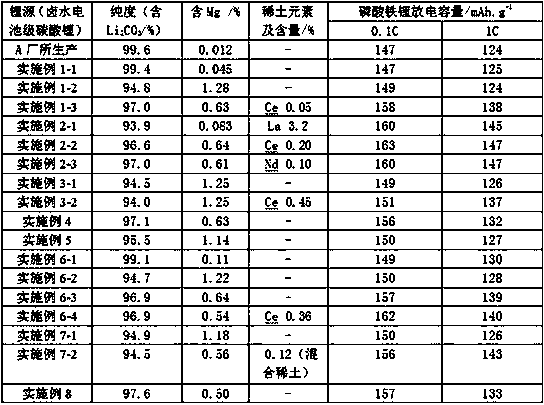

Examples

Embodiment 1

[0026] Embodiment 1 (including Embodiment 1-1, 1-2, 1-3)

[0027] The old brine with a Li content of 1500mg / L adopts ion-selective membrane separation technology (old brine membrane separation method) to enrich lithium and reduce magnesium, moderately remove magnesium with sodium carbonate solution, concentrate, and obtain a lithium chloride lithium-rich solution with a Li content of 12.5 g / L, the Mg content is 13.2 mg / L, and the Ca content is 2.8 mg / L; the Li / Ca mass ratio of the solution is ≈4464, and the Mg / Li mass ratio is ≈0.00106.

Embodiment 1-1

[0029] Take 3L of lithium-rich solution, add it to the reaction kettle, raise the temperature to 70°C, and add Na 2 CO 3 solution (wherein, Na 2 CO 3 content of 282g / L, Mg content of 29mg / L; Na 2 CO 3 The dosage is 1.16 times of the stoichiometric amount) 1.18L, after adding Na 2 CO 3 solution, continue to stir and react for 100 minutes, filter, and then fully wash the filter cake with 600 mL of pure water at a temperature of 80°C, and then dry the obtained lithium carbonate filter cake (containing 29.5% of attached water) at 130°C to obtain brine battery grade The lithium carbonate product was 159.7g; the primary yield of lithium was 79.50%.

[0030] The product is Li 2 CO 3 content of 99.4%, Mg content of 0.045%, Ca content of 0.005%, D 50 (average particle size) 3.6 μm.

[0031] After the synthesis is completed, the resulting synthetic mother liquor and washing liquid after filtration contain about 9g / L of Li 2 CO 3 , can be recovered according to the convention...

Embodiment 1-2

[0033] Take 3L of lithium-rich solution, add it to the reactor, raise the temperature to 90°C, add MgCl 2 ·6H 2 O 17.5g, stirring and dissolving; adding Na under stirring condition 2 CO 3 solution (wherein Na 2 CO 3 content of 282g / L, Mg content of 29mg / L; dissolved polyethylene glycol 0.51g; Na 2 CO 3 The dosage is 1.16 times of stoichiometric) 1.18L, add Na 2 CO 3 Solution, continue to stir and react for 60 minutes, filter, and then fully wash the filter cake with 670 mL of pure water at a temperature of 85 ° C, and then dry the obtained lithium carbonate filter cake at 230 ° C to obtain 170.7 g of brine battery-grade lithium carbonate product; The primary yield is 81.02%.

[0034] The product is Li 2 CO 3 content of 94.7%, Mg content of 1.28%, Pb content 50 4.2 μm.

[0035] After the synthesis is complete, the resulting synthetic mother liquor after filtration contains Li 2 CO 3 About 8g / L, containing about 56g / L NaCl, recovered according to conventional meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com