LED light source module

A technology of LED light sources and modules, which is applied to the structure of modules, light strips, and combined lamps, can solve problems such as shortened service life, insufficient luminous flux, and high failure rate, and achieve extended service life, improved light efficiency, and integrity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

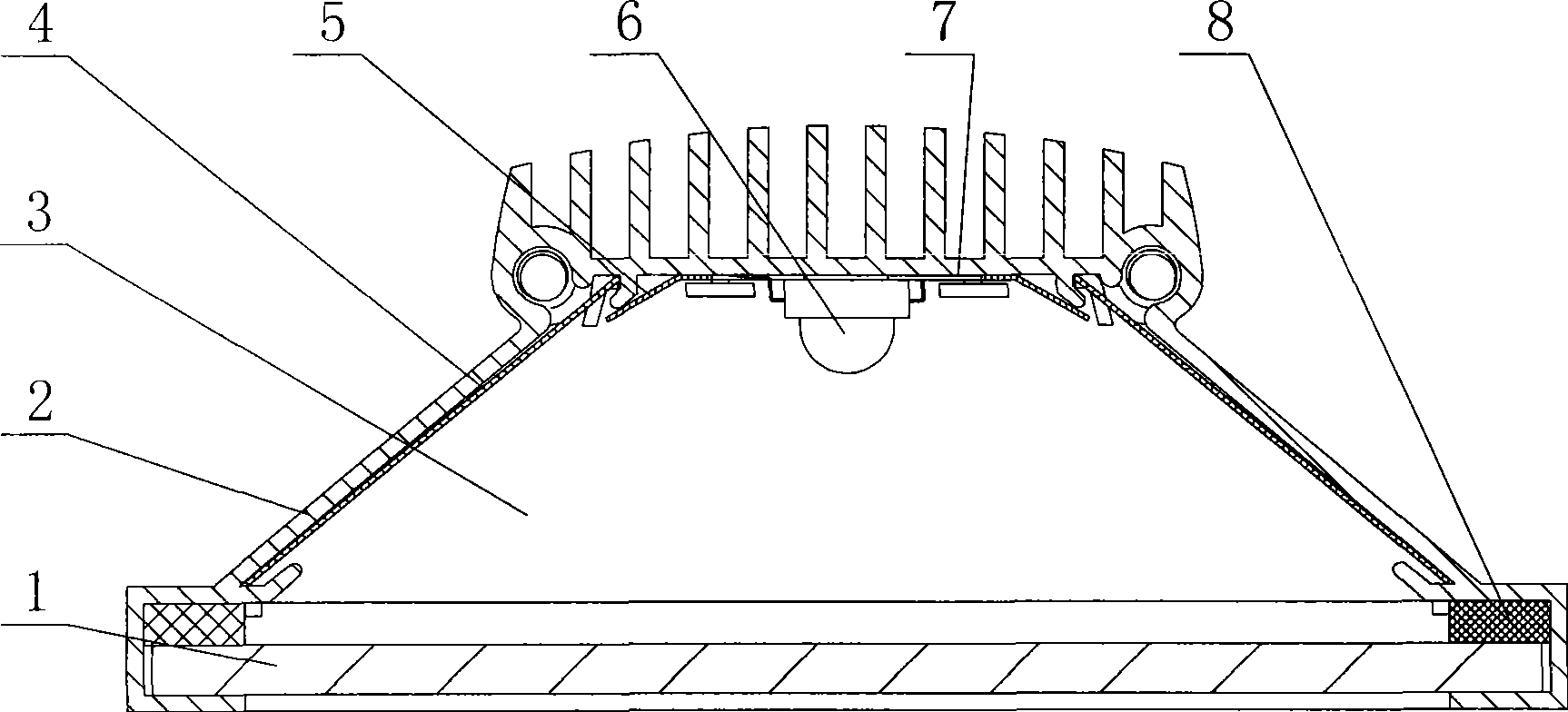

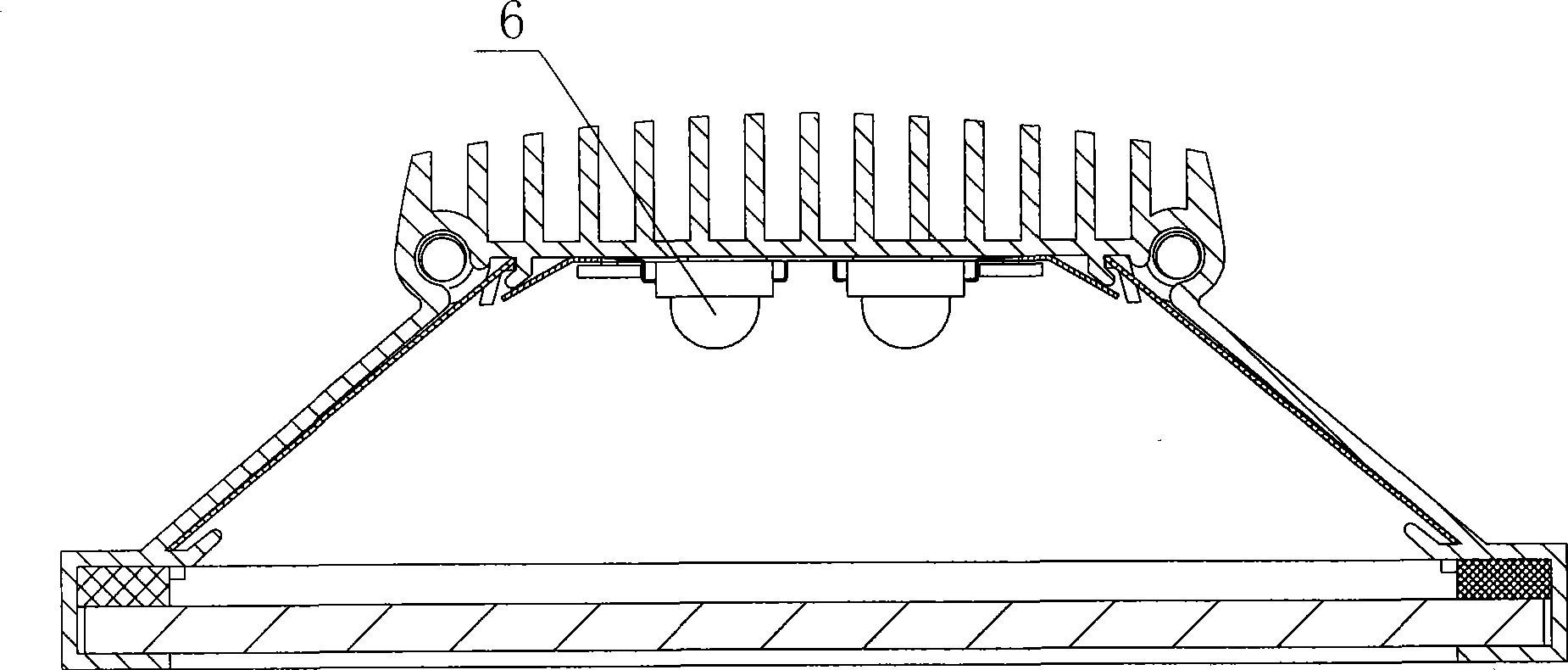

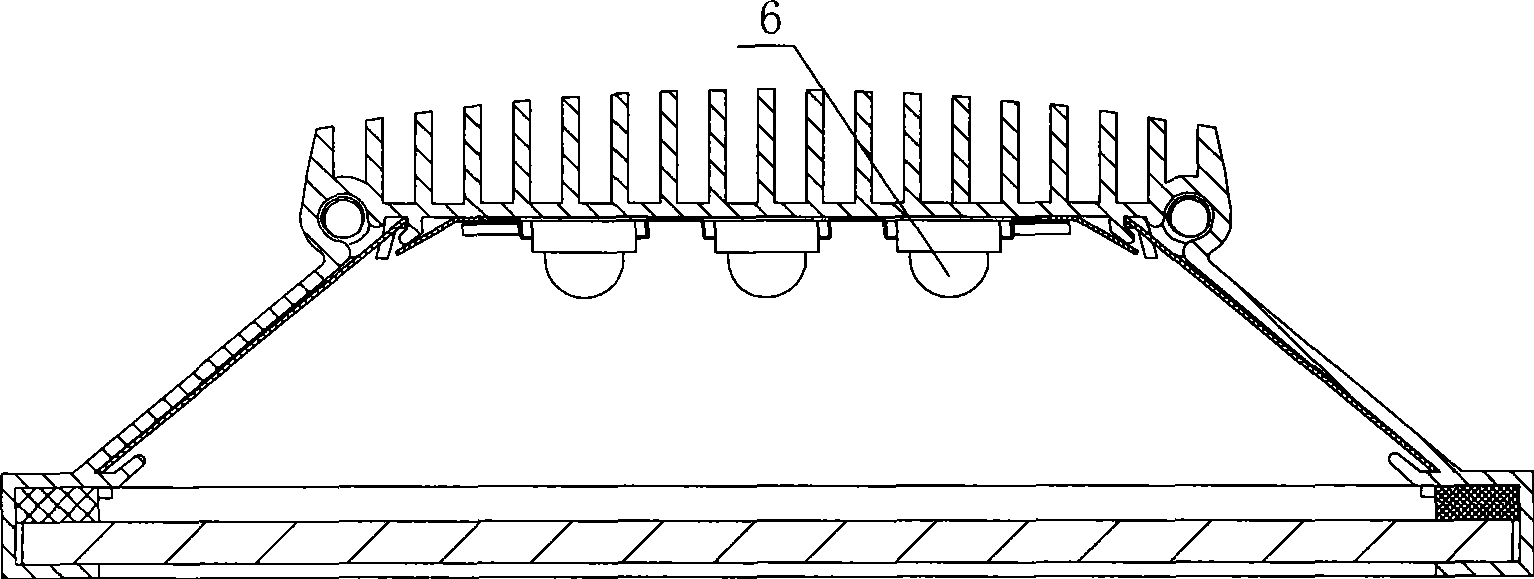

[0018] Figure 1, figure 2 , Fig. 3, shown in Fig. 4, embodiment is to use 15 LED light source modules.

[0019] LED light source module, including translucent cover 1, lamp body 2, end cover 3, side reflector 4, top reflector 5, LED light source 6, PCB board 7, sealing strip 8, PCB board 7 is connected inside the lamp body 2 At the top, the LED light source 6 is welded on the top PCB board 7 inside the lamp body 2 by soldering. The LED light source 6 can be monochromatic light or a combination of multiple colors. LED light sources 6 can be used in different quantities to form modules of different sizes and powers, so as to meet the requirements of different lamps on the size and power of the light sources. At the same time, the LED light sources 6 in the module can be arranged in one or more rows (as shown in FIG. 1 ). The lamp body 2 is made of aluminum alloy through extrusion molding. The lamp body 2 is provided with a concave structure, and heat dissipation ribs are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com