Gradual change photochromic and electrochromic polarized spectacle lens and production method thereof

An electrochromic and production method technology, which is applied in the directions of glasses/goggles, optics, optical components, etc., can solve the problems of fixed light blocking degree, low light transmittance, single polarizer blocking sunlight, etc., and achieves strong practicability, The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

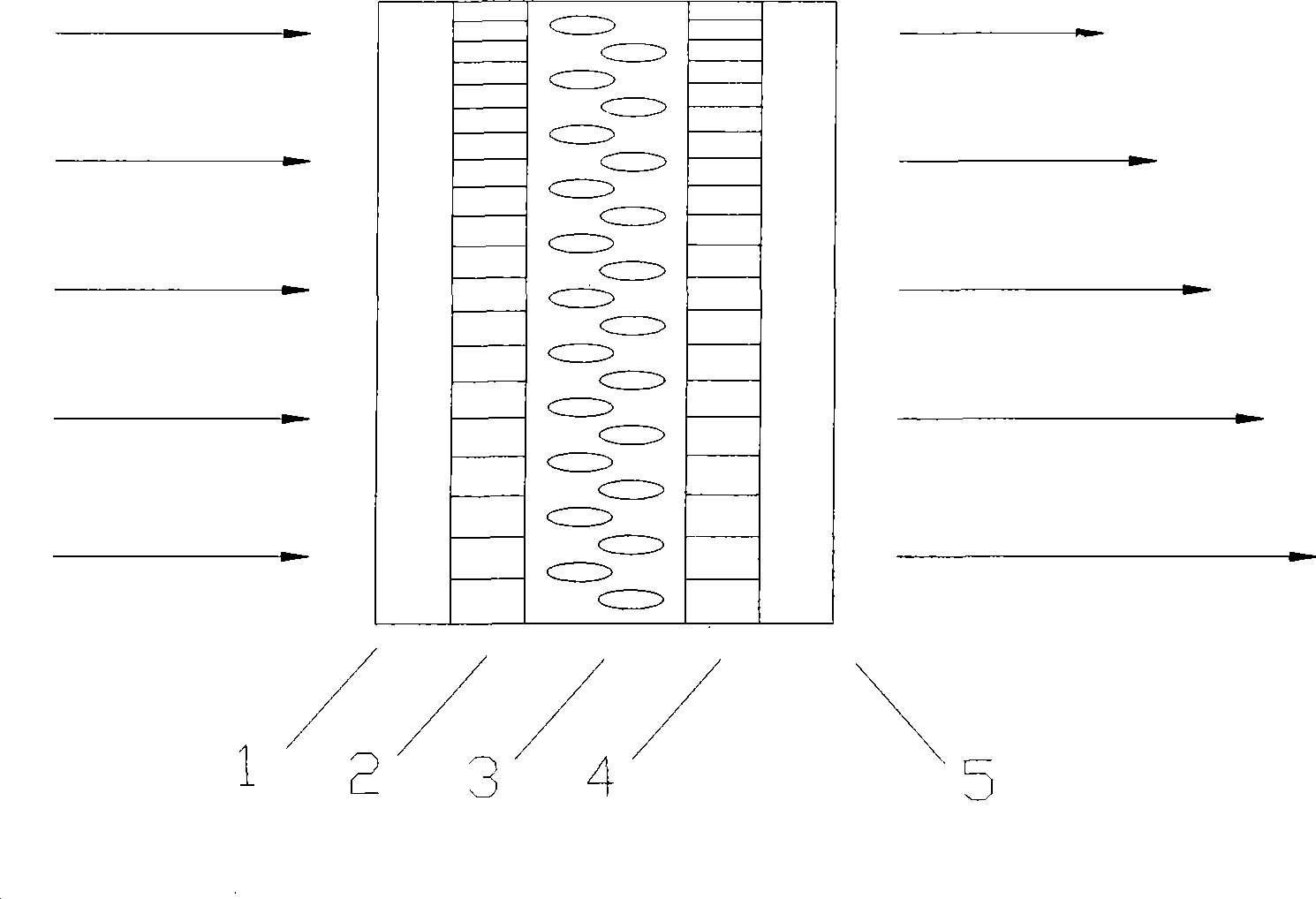

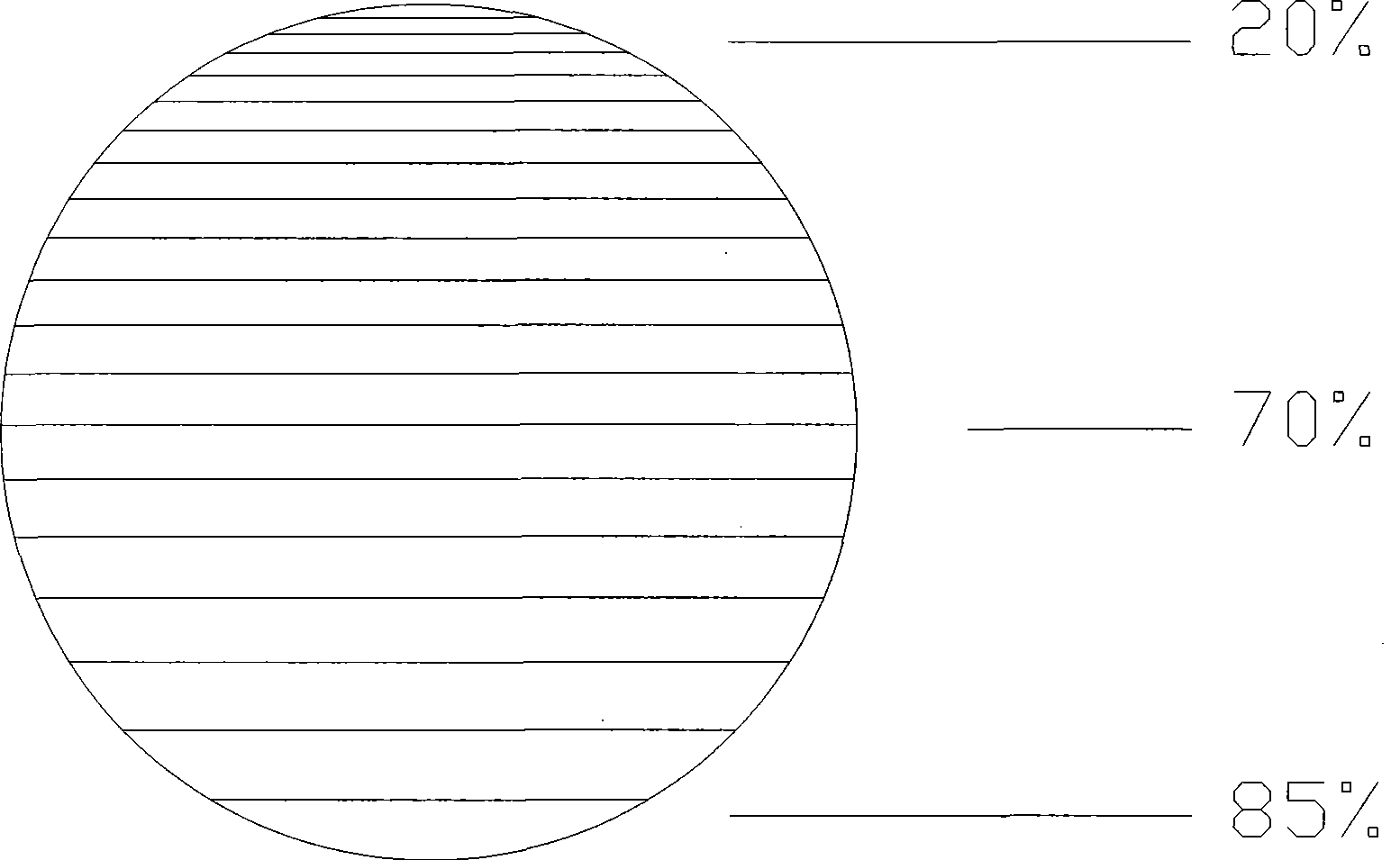

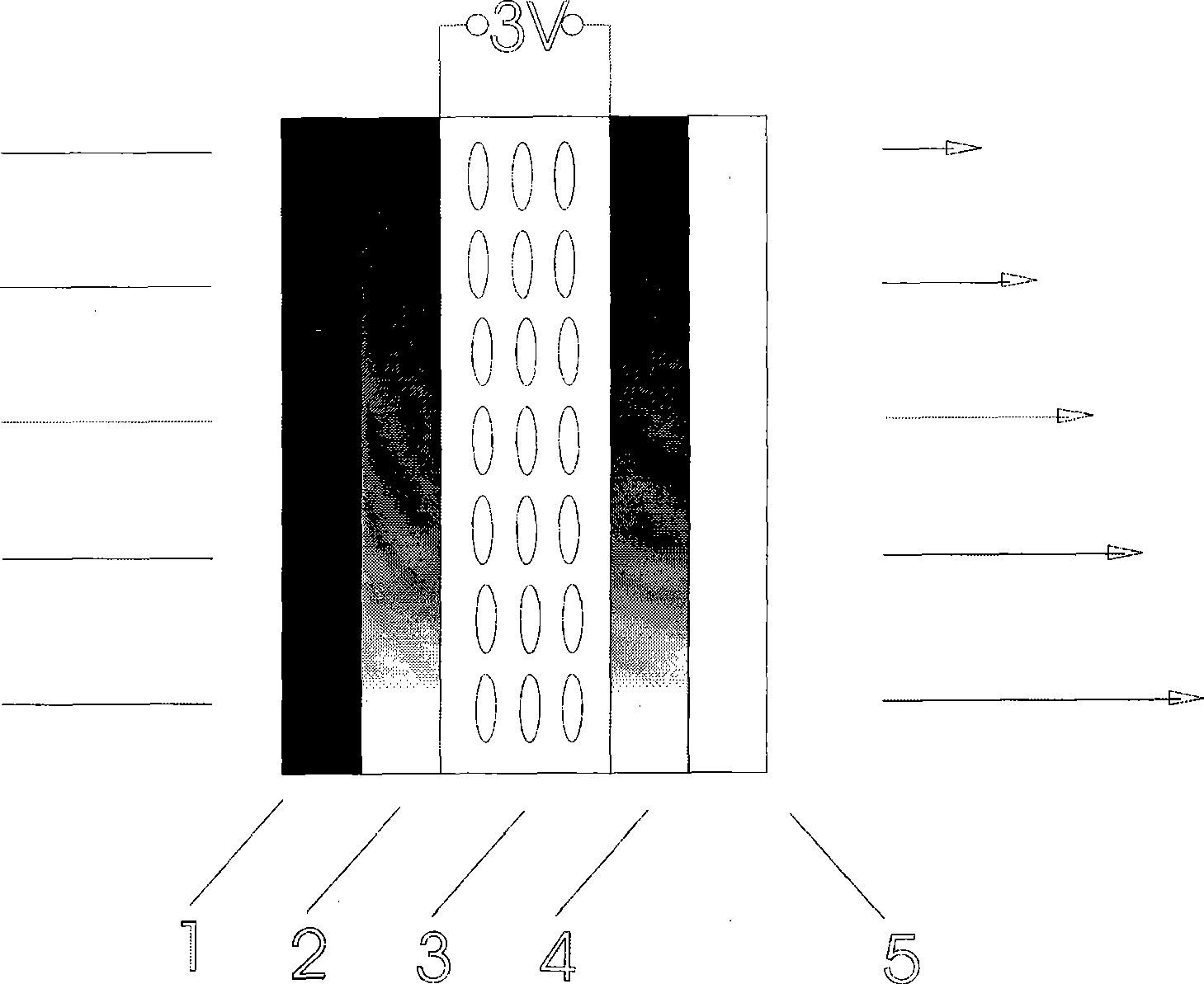

[0022] Depend on figure 1 It is known that the progressive photochromic and electrochromic polarized spectacle lenses of the present embodiment comprise a photochromic resin lens 1, a gradient front polarizing film 2, a liquid crystal box 3, a gradient rear polarizing film 4, and a transparent resin lens 5. .

[0023] The production method of the present embodiment is as follows: a production method of gradient photochromic and electrochromic polarized spectacle lenses is to successively make photochromic resin lens, gradient front polarizing film, liquid crystal cell, gradient rear polarizing film, resin The protective lens is discharged into the glass mold, and UV photosensitive adhesive is coated in the middle of each layer. After the glue is applied, the mold is clamped and irradiated under the ultraviolet lamp for 10-20 minutes. After the photosensitive adhesive is completely cured, it is removed from the mold, and the corners Polished neatly, after inspection of all opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com