Preparation method of flexible graphite composite bipolar plate of proton exchange membrane fuel cell

A technology of proton exchange membrane and flexible graphite, which is used in fuel cell parts, fuel cells, battery electrodes, etc., can solve problems such as large thickness, enhance mechanical properties, reduce the probability of fine cracks and bubbles, and increase compactness. Effect

Active Publication Date: 2010-12-01

SUNRISE POWER CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The bipolar plate prepared by this process has good electrical conductivity, mechanical and sealing properties, but its thickness is relatively large, which has certain restrictions on the assembly and practical application of battery packs, especially for vehicles.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

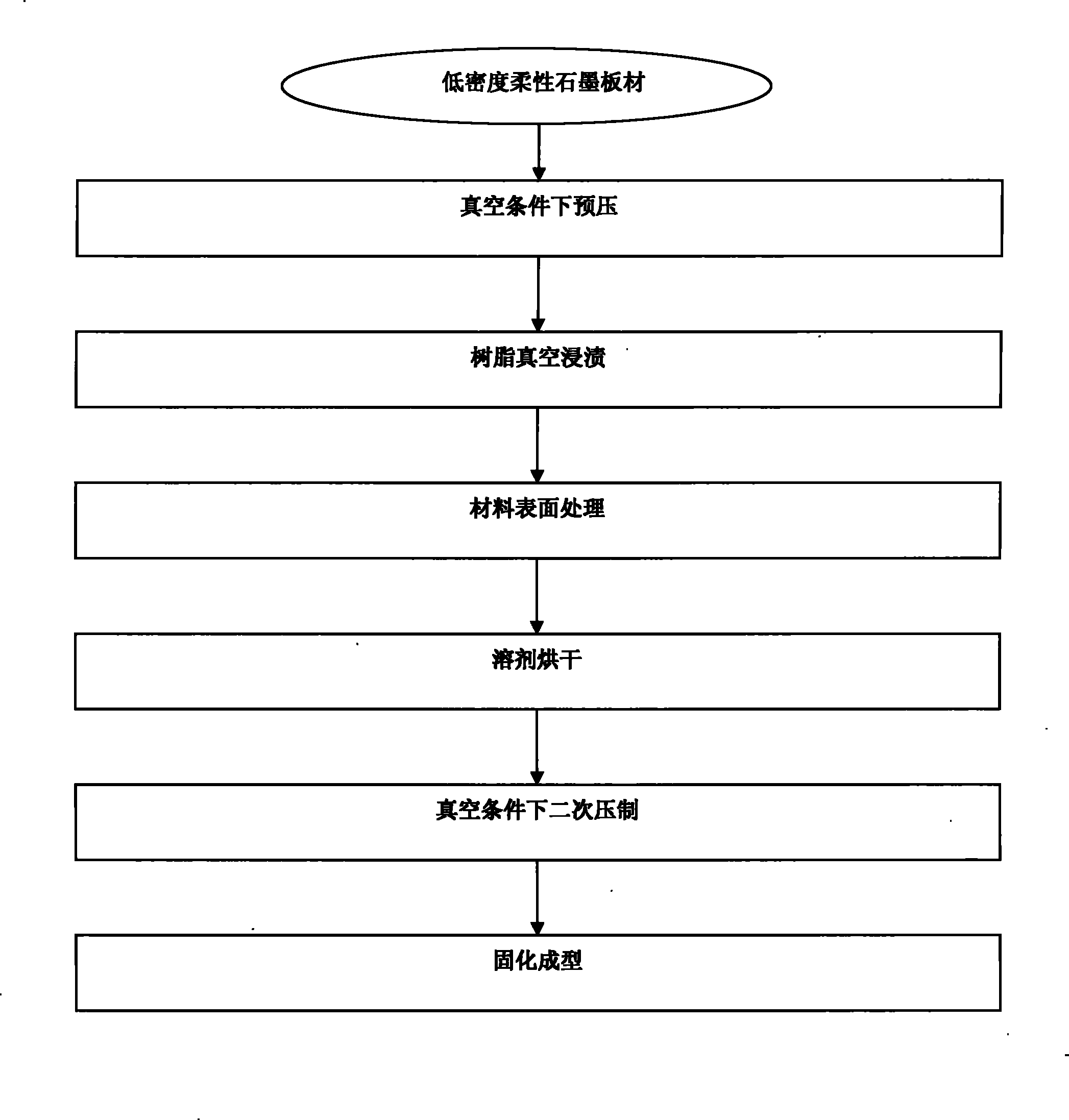

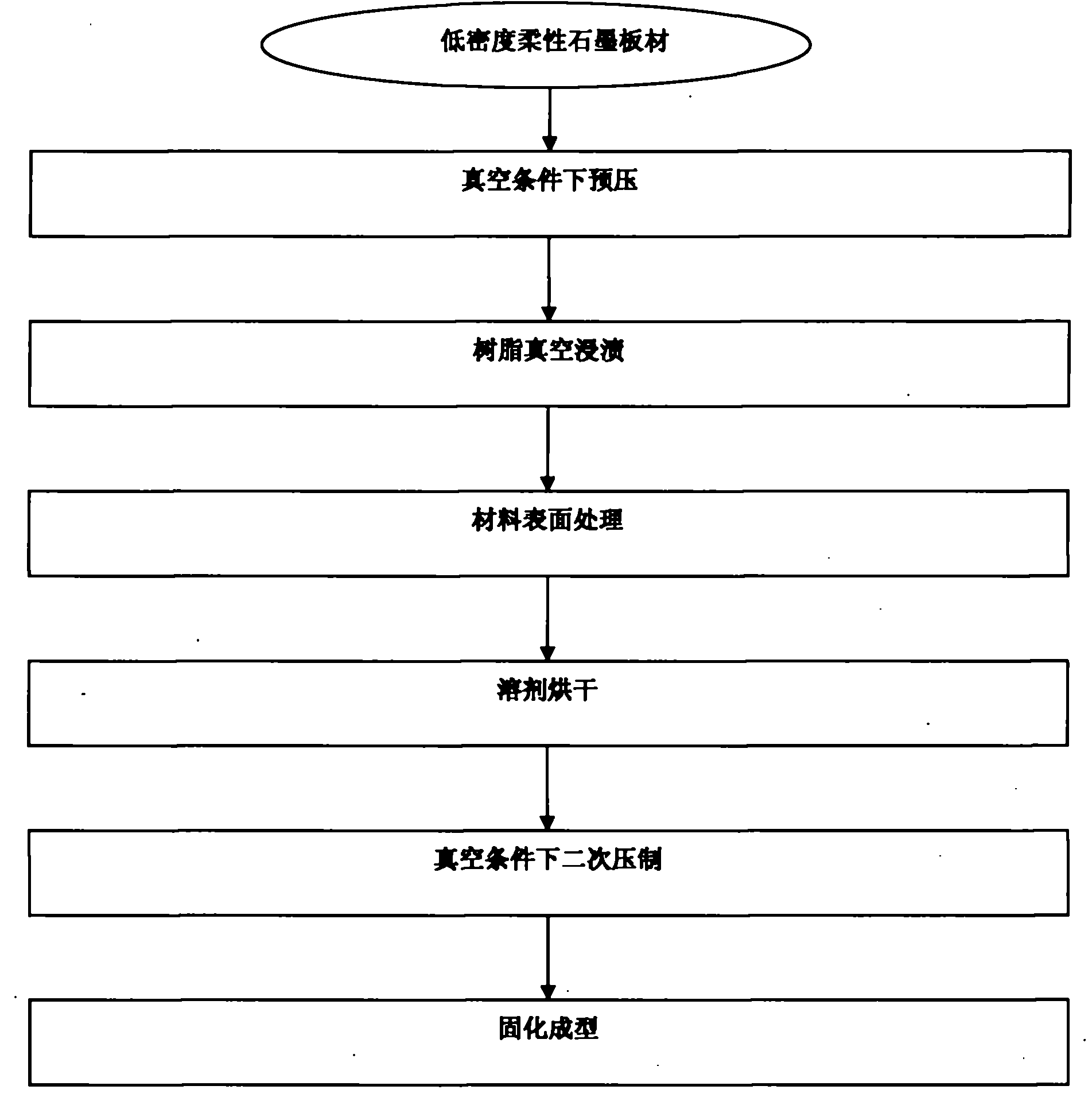

The invention relates to a preparation method of a flexible graphite composite bipolar plate of a proton exchange membrane fuel cell, which comprises anode flow field, a cathode flow field and a water plate made of flexible graphite plates, which are assembled into a bipolar plate with a sealing frame and a partition plate. The method is that firstly low density flexible graphite plates are prepressed into plates with the density being of 0.65 to 0.75 g / cm<3> under vacuum, then the plates are dipped in low viscosity resin solution under vacuum, after surface treatment and drying, the plates are pressed through a roll or a die out the flow field, and a flow filed and a water plate made of polymer / flexible graphite composite plates is obtained after the plates are solidified. At last, the flow filed and the water plate made of the polymer / flexible graphite composite plates with the sealing frame and the partition plate are assembled into a bipolar plate. The preparation method has the advantages that the resin content in the pole plate is easier to be controlled, the sealing property to gas is good, the mechanical property is good, the thickness of the pole plate is convenient to bereduced, the preparation technology is simple, the mass production is easy, and the preparation method is significant for promoting the industrialized development of the fuel cell.

Description

A preparation method of a flexible graphite composite bipolar plate for a proton exchange membrane fuel cell technical field The invention relates to the field of proton exchange membrane fuel cells, in particular to a preparation process for flexible graphite composite bipolar plates of proton exchange membrane fuel cells. Background technique The bipolar plate is a key component in the proton exchange membrane fuel cell (PEMFC). In the fuel cell, it plays the role of distributing fuel gas and air, realizing the electrical connection between monolithic cells, taking out waste heat from the active area, and preventing gas and coolant leakage as well as facilitating water management in the battery, among other functions. In addition, the cost of the bipolar plate accounts for about 30%-45% of the total cost of the battery, and its mass accounts for 80% of the total weight, so it also has a significant effect on the mass, volume and cost of the entire PEMFC system. It can b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/88H01M8/02H01M8/0258

CPCY02E60/50Y02P70/50

Inventor 杜超明平文傅云峰罗晓宽

Owner SUNRISE POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com