Preparation method of flexible graphite composite bipolar plate of proton exchange membrane fuel cell

A technology of proton exchange membrane and flexible graphite, which is used in fuel cell parts, fuel cells, battery electrodes, etc., can solve problems such as large thickness, increase density, enhance gas tightness and mechanical strength, and reduce fine cracks and the effect of the probability of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

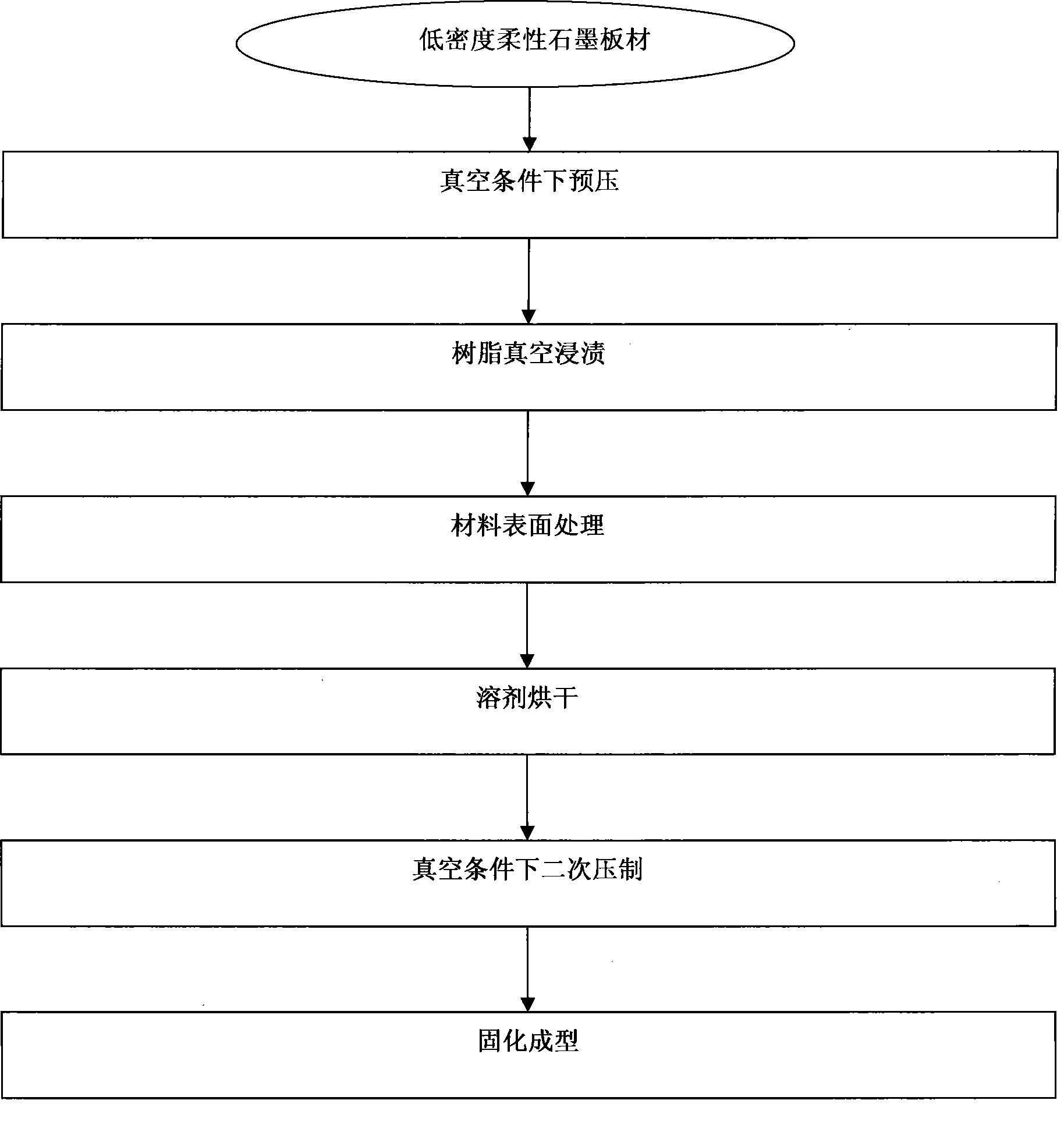

Method used

Image

Examples

Embodiment 1

[0021] The present invention adopts the attached figure 1 The preparation process shown. Select thickness as 7mm and density as 0.20g / cm 3 The flexible graphite sheet is pre-pressed under vacuum (vacuum degree-0.08MPa), the pre-pressing pressure is 1.5MPa, and the density is 0.69g / cm 3 of plates. Epoxy resin was selected as the polymer filler, phenolic resin was used as the curing agent, and ethanol was selected as the solvent to prepare a resin solution with a mass fraction of 40%. Vacuum impregnation (vacuum degree-0.08MPa) of the plate was carried out for 18 hours with the resin solution. After taking it out, use the post-treatment method of alcohol scrubbing to treat the resin remaining on the surface of the impregnated board, and dry it at 80°C for 2 hours. The dried plate is rolled out of the flow field flow channel by secondary rolling under vacuum conditions (vacuum degree -0.08MPa), and the rolling pressure is 10Mpa; finally, it is cured at 175°C by program heatin...

Embodiment 2

[0026] The difference from Example 1 is that a resin solution with a mass fraction of 20% is selected. The final thickness is 1mm and the density is 1.79g / cm 3 polymer / flexible graphite electrode composite plate.

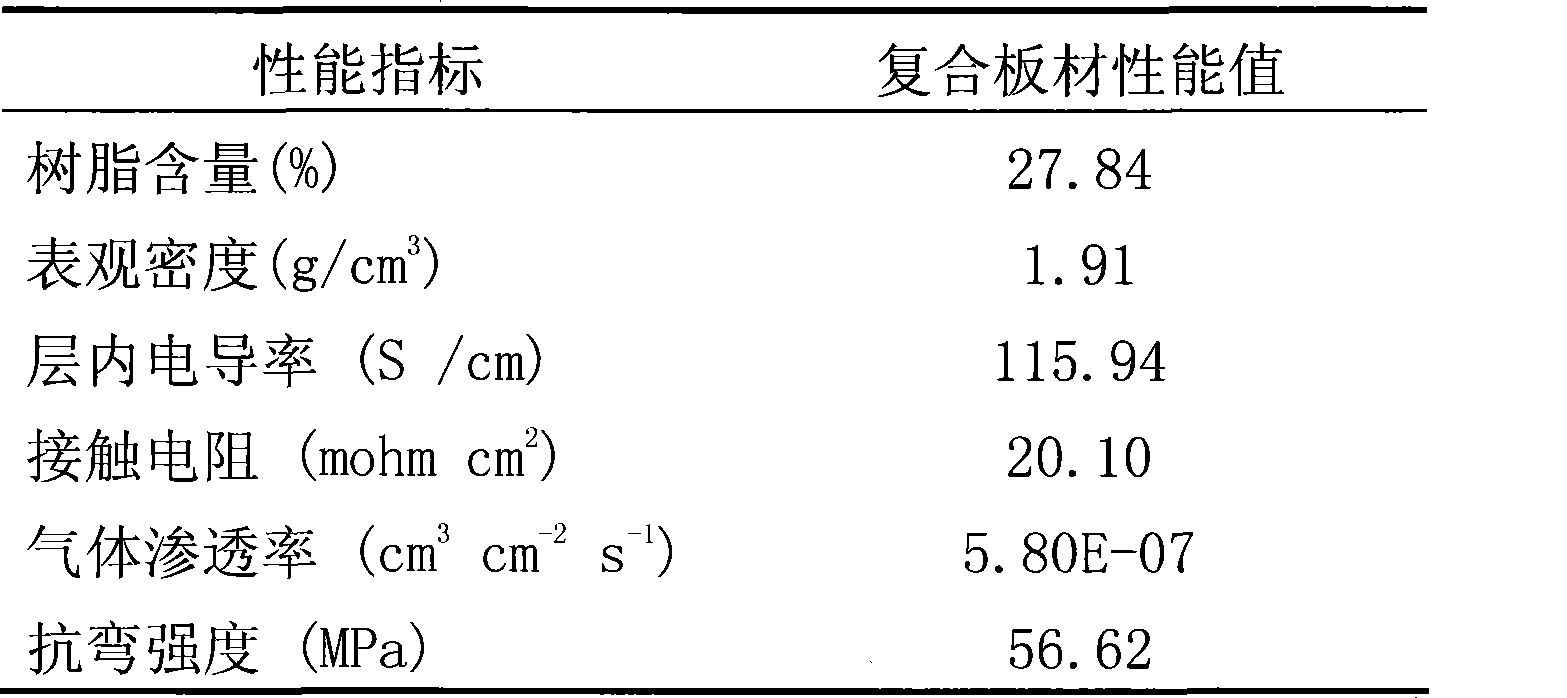

[0027] The performance analysis of the prepared plate is as follows:

[0028] Table 2

[0029]

Embodiment 3

[0031] The difference from Example 1 is that a resin solution with a mass fraction of 23% is selected. The final thickness is 1mm and the density is 1.81g / cm 3 polymer / flexible graphite electrode composite plate. The performance analysis of the prepared plate is as follows:

[0032] table 3

[0033]

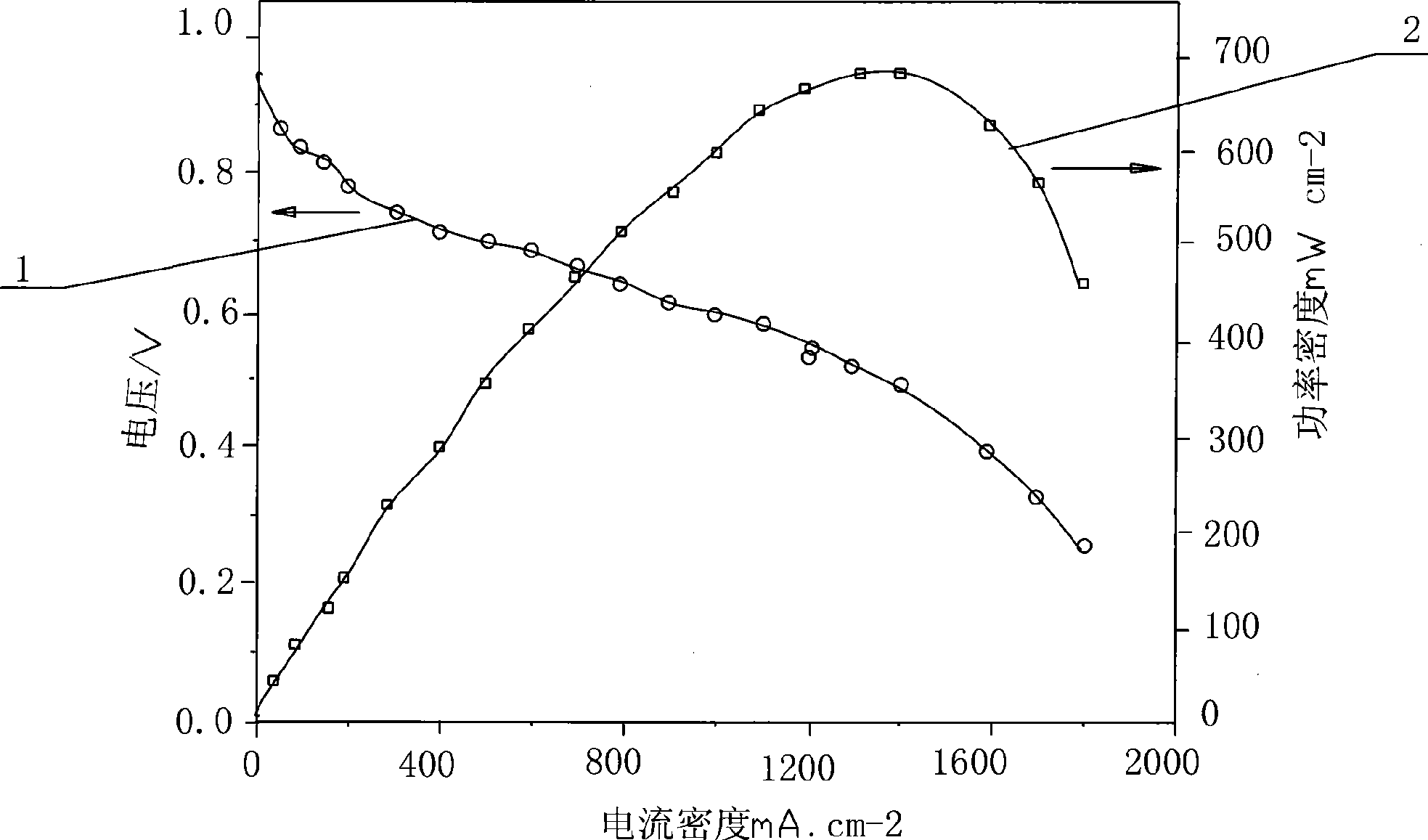

[0034] The bipolar plate prepared by using the composite material is assembled into a battery, and its performance is as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com