Corrugated asphalt waterproofing sheet

A waterproof board and corrugated technology, applied to roofs, roofs, buildings, etc. that use flat/curved panels, can solve problems such as loss of bonding function, difficulty in bonding waterproof coils, and large water leakage hazards, so as to improve the overall performance. , Improve the optical effect, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A corrugated asphalt waterproof board in this embodiment, the corrugated asphalt waterproof board is made by using wood fiber as a raw material, spraying glue on the surface to make a corrugated tile shape, and then impregnating asphalt. Its preparation method specifically comprises the following steps:

[0036] 1) Make wood pulp into a slurry with a concentration of about 2% (mass fraction), and then use special equipment to copy the slurry into a quantitatively uniform (uniform density) substrate, press and dry the substrate to A board with a moisture content of 8% was obtained;

[0037] Among them, before the plate is dry, the patterns are pressed on both sides; the surface of the plate is sprayed with glue before the plate is dried; the glue sprayed is made of special glue to control the water absorption of the plate and the amount of asphalt impregnation;

[0038] 2) Press the dried plate into a corrugated tile shape at a high temperature of about 250°C;

[0039]...

Embodiment 1

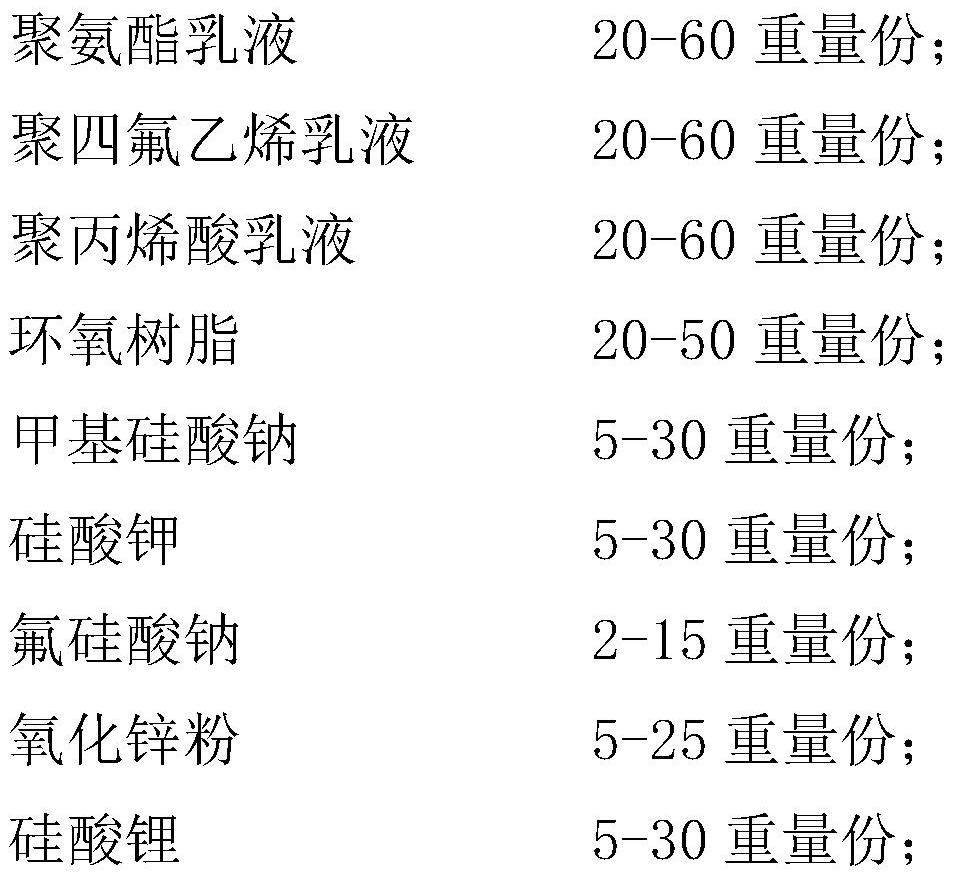

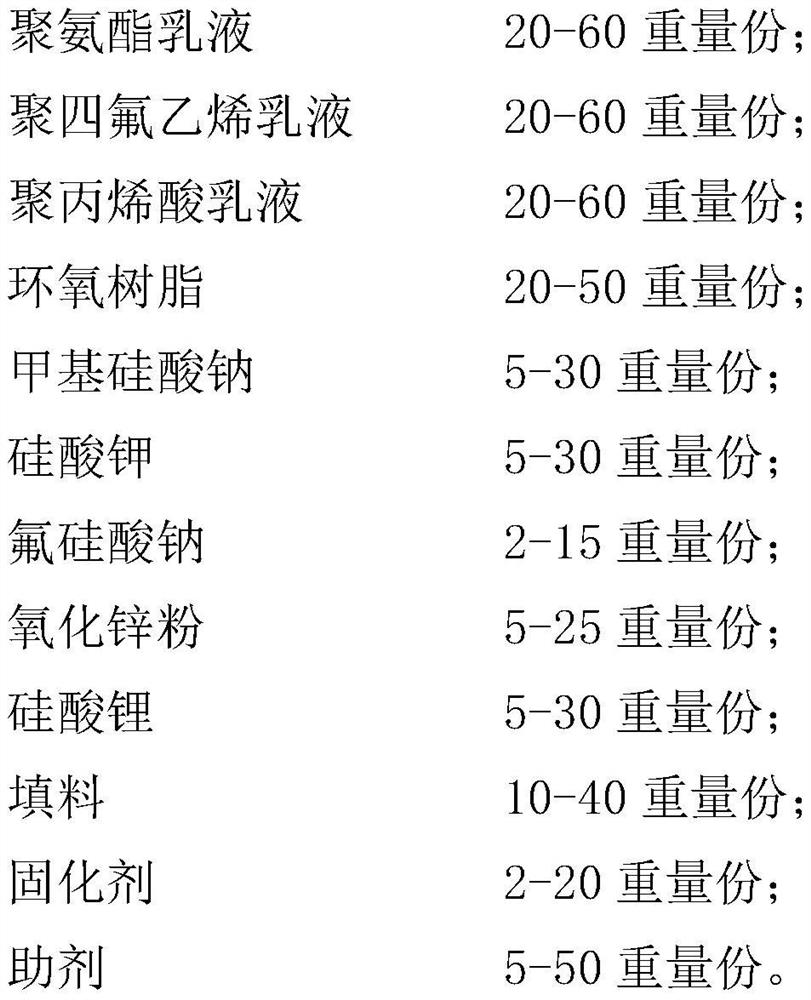

[0061] Described composite coating comprises the raw material of following weight portion:

[0062]

[0063]

[0064] The preparation method of composite paint, it may further comprise the steps:

[0065] 1) Add polyurethane emulsion, polyacrylic acid emulsion, polytetrafluoroethylene emulsion, and epoxy resin into the reaction kettle, control the temperature at 40-90°C, and stir for 1-4h;

[0066] 2) Add sodium methyl silicate, potassium silicate, sodium fluorosilicate, zinc oxide powder, lithium silicate dolomite micropowder, nano silicon nitride powder, nano boron carbide powder and nano zirconia powder to the reaction kettle, control The temperature is 40-50°C; stir for 0.5-2.5h;

[0067] 3) Add auxiliary agent and curing agent into the reaction kettle, control the temperature at 30-40° C.; stir for 10-45 minutes to obtain composite coating.

[0068] Then the composite coating that is made is sprayed on the plate surface after pressing and shaping, spraying 1-5 tim...

Embodiment 2

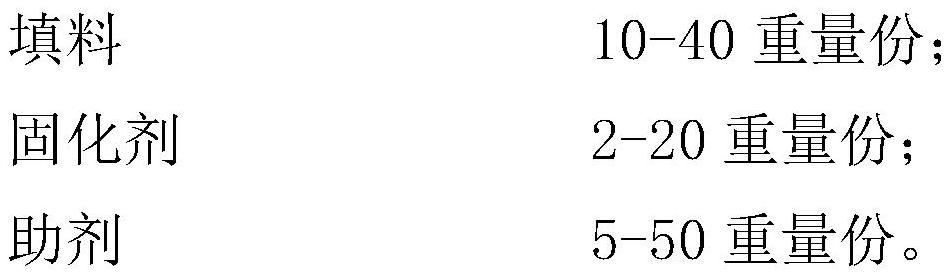

[0070] Described composite coating comprises the raw material of following weight portion:

[0071]

[0072]

[0073] The preparation method of composite paint, it may further comprise the steps:

[0074] 1) Add polyurethane emulsion, polyacrylic acid emulsion, polytetrafluoroethylene emulsion, and epoxy resin into the reaction kettle, control the temperature at 40-90°C, and stir for 3 hours;

[0075] 2) Add sodium methyl silicate, potassium silicate, sodium fluorosilicate, zinc oxide powder, lithium silicate dolomite micropowder, nano silicon nitride powder, nano boron carbide powder and nano zirconia powder to the reaction kettle, control The temperature is 40-50°C; stir for 1.5h;

[0076] 3) Add auxiliary agent and curing agent into the reaction kettle, control the temperature at 30-40° C.; stir for 30 minutes to obtain a composite coating.

[0077] The prepared composite paint is sprayed on the surface of the plate after pressing and shaped, sprayed 2 times (every ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com