Graphite bipolar plate preparation method and graphite bipolar plate prepared by same

A bipolar plate and graphite plate technology, which is applied in the preparation of graphite bipolar plates and the field of graphite bipolar plates, can solve the problems affecting the gas permeability and mechanical properties of materials, the limitations of stack assembly and practical application, and the unsatisfactory resin impregnation effect, etc. problem, achieve the effect of enhancing gas permeability and mechanical strength, simple and reliable preparation method, and reducing the probability of microcracks and bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

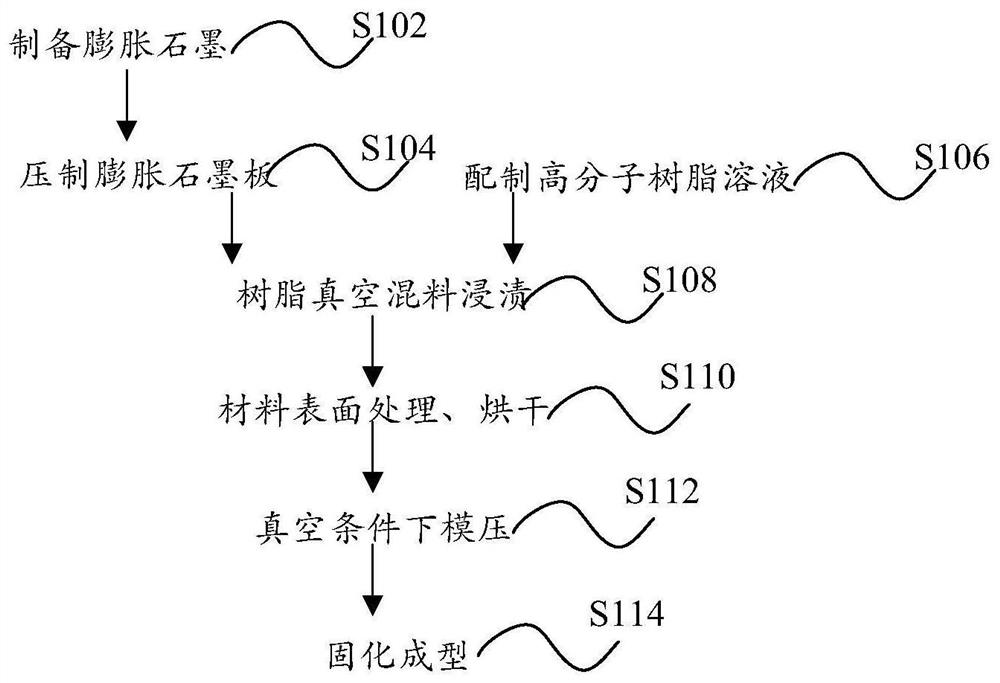

[0033] Such as figure 1 Shown, according to the graphite bipolar plate preparation method of the embodiment of the present invention, comprises the following steps:

[0034] S102, preparing expanded graphite: performing intercalation treatment on flake graphite, and instantaneously expanding at high temperature to obtain the low-density flexible expanded graphite, and the instantaneous expansion temperature is 900°C-1000°C.

[0035] S104, Pressed expanded graphite plate: Press low-density flexible expanded graphite into expanded graphite plate, that is, the thickness is 7mm, and the density is 0.2-1.0g / cm 3 flexible graphite sheet;

[0036] S106, preparing a polymer resin solution: mixing epoxy resin and phenolic resin in a ratio of 1:2, using ethanol as a solvent to prepare a solution with a viscosity of 20mPa·s and a resin mass fraction of 40%;

[0037] S108, resin vacuum mixing impregnation: pour the resin solution into the flexible graphite plate under the vacuum degree ...

Embodiment 2

[0043] The difference from Example 1 is that a resin solution with a mass fraction of 25% is selected. The final thickness is 0.7mm and the density is 1.9g / cm 3resin / flexible graphite composite bipolar plates.

[0044] After testing, the resin content in the bipolar plate is 23.31%, the electrical conductivity at 25°C is 552.14S / cm, the tensile strength is 13MPa, and the thermal conductivity is 56.13W / (m·k).

Embodiment 3

[0046] The difference from Example 1 is that a resin solution with a mass fraction of 45% is selected. The final thickness is 0.7mm and the density is 1.85g / cm 3 resin / flexible graphite composite bipolar plates.

[0047] After testing, the resin content in the bipolar plate is 32%, the electrical conductivity at 25°C is 228.52S / cm, the tensile strength is 37MPa, and the thermal conductivity is 118.25W / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com