Copper-sulfur separation floatation method

A flotation, chalcopyrite technology, applied in the field of beneficiation engineering, can solve the problems of complex ore properties, low gold leaching rate, increased sodium cyanide consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

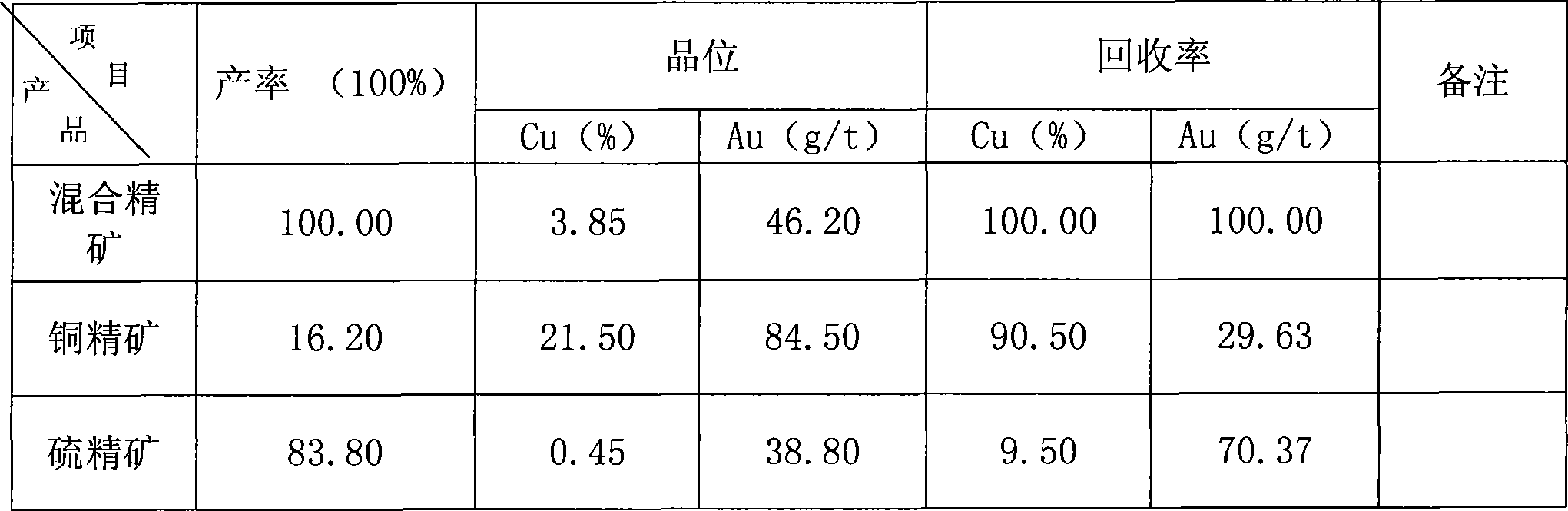

[0022] The method of the present invention is based on the charge on the chalcopyrite and pyrite mineral surfaces in the mixed gold concentrate, the point of zero charge (PZC) and the pH value of the point of zero charge (PH PZC ) difference, use lime as a regulator to adjust the pH value of the slurry of mixed gold concentrate, and control the pH to 12.5-13; use combined inhibitors CaO, Na 2 SO 3 The mixture with NaCN inhibits the floatability of pyrite, where CaO dosage is 40kg / t, Na 2 SO 3 The dosage is 500g / t, and the dosage of NaCN is 50g / t; the composition of butylxanthate and pentylxanthate is used as a collector to change the floatability of chalcopyrite, and the dosage of butylxanthate is 20g / t, the dosage of pentyl xanthate is 40g / t; the foaming agent adopts No. 2 flotation oil, and the dosage of No. 2 oil is 5g / t; The flotation process of two-time sweeping and three-time selection. Among them, the grinding fineness of -200 mesh accounts for 95%. Flotation uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com