Method for brewing vinegar by solid and liquid combination fermentation

A liquid and solid technology, applied in the field of liquid vinegar brewing and solid state, can solve the problems of large diameter of fermentation tank, low utilization rate of raw materials, unfavorable large-scale production, etc., and achieve the effect of improving the rate of vinegar production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

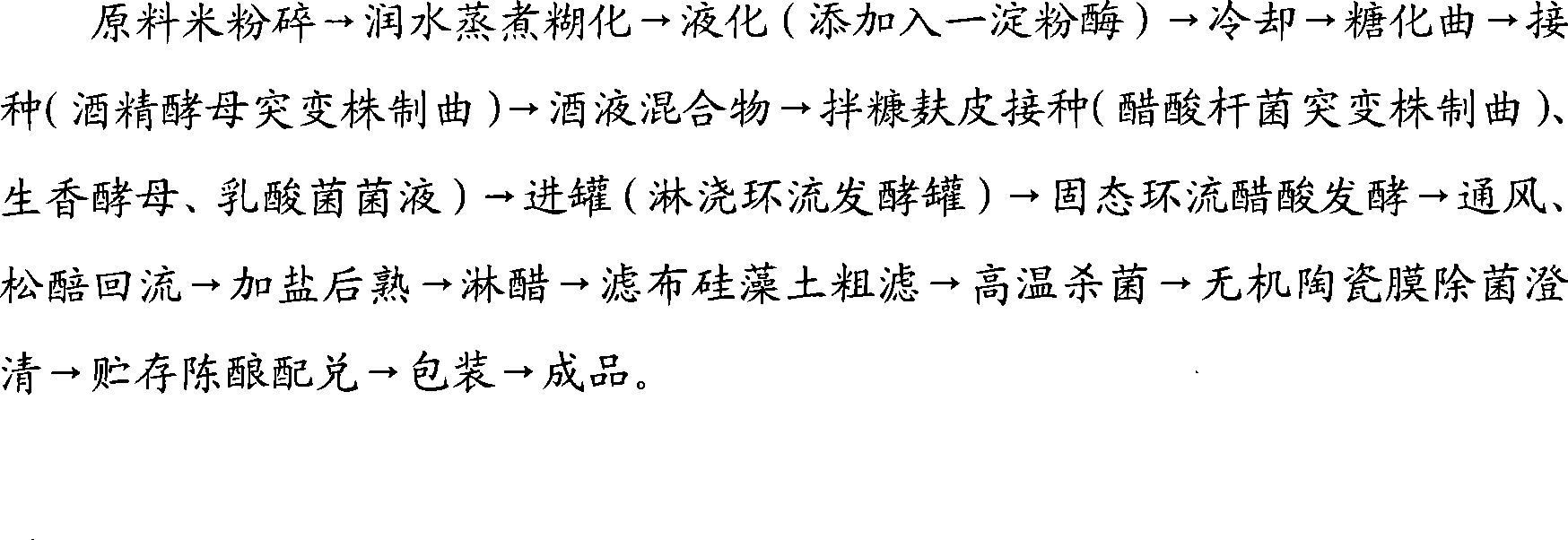

[0029] The method for making vinegar by combining solid state and liquid state through fermentation is characterized in that it comprises the following steps:

[0030] (1) Raw material rice is crushed, steamed and gelatinized by moistening water, the fineness of rice flour is 70 mesh, the ratio of water to rice flour is 5:1; the gelatinization temperature is 95--100°C, when the temperature rises to 95°C, keep it for 30 minutes ;

[0031] (2) Add amylase for saccharification: after gelatinization, cool to below 60°C, start adding saccharified koji, add 10kg saccharified koji for every 100kg of rice flour;

[0032] (3), inoculate alcoholic yeast strain and carry out alcoholic fermentation to obtain wine mash, according to kind of alcoholic yeast adds 1kg yeast inoculation by 1000kg rice flour, fermentation time 72 hours;

[0033] (4) After the fermented wine mash is mixed with bran and rice bran, the weight ratio of the mixing material is: wine mash, bran, and rice bran 1:1.5:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com