Intelligent false tooth manufacturing method

A manufacturing method and technology of dentures, applied in the field of dentures, can solve problems such as poor patient tolerance, inability to use normally, and inability to achieve stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An intelligent denture manufacturing method, including making a denture model, porcelain process, and making a denture bracket, using scanning and 3D printing technologies to make the denture model; making the denture bracket is specifically a denture that is installed according to needs, and the manufacturing is matched with the denture The bracket is installed on the denture dental model; the porcelain process is carried out as follows:

[0060] 1. Preparation of adhesive: Take 1L of ethanol solution with a volume fraction of 25%, set the stirring speed at 130r / min for stirring, add 10g of sodium alginate under stirring conditions, stir to completely dissolve the sodium alginate, and then continue stirring Slowly add 0.7g of titanium dioxide, after the addition, continue to stir for 12min, so that the titanium dioxide is uniformly dispersed to obtain a dispersion solution; then the temperature of the dispersion solution is raised to 40°C, and under the condition of kee...

Embodiment 2

[0065] An intelligent denture manufacturing method, including making a denture model, porcelain process, and making a denture bracket, using scanning and 3D printing technologies to make the denture model; making the denture bracket is specifically a denture that is installed according to needs, and the manufacturing is matched with the denture The bracket is installed on the denture dental model; the porcelain process is carried out as follows:

[0066] 1. Preparation of adhesive: Take 1L of ethanol solution with a volume fraction of 20%, set the stirring speed at 120 / min for stirring, add 7g of sodium alginate under stirring conditions, stir to completely dissolve the sodium alginate, and then continue stirring Slowly add 0.5g of titanium dioxide, after the addition, continue to stir for 10min, so that the titanium dioxide is uniformly dispersed to obtain a dispersion solution; then the temperature of the dispersion solution is raised to 45°C, and under the condition of keepi...

Embodiment 3

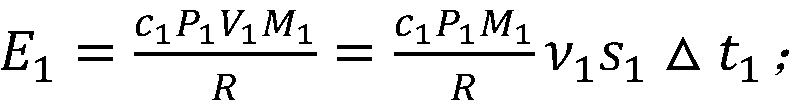

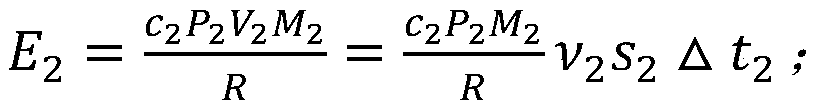

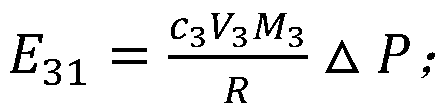

[0071] An intelligent denture manufacturing method. During the spraying and drying process, the temperature of the denture mold in the fluidized bed coating machine is monitored in real time, and then the temperature of the denture mold is controlled in real time to ensure that the temperature of the denture mold can be adjusted. Controllable; the temperature when the porcelain powder suspension is combined with the denture dental mold is an important factor to ensure the quality of the porcelain on the denture. If the temperature is not well controlled, the porcelain powder suspension and the dental mold may not be fully or partially combined, resulting in the failure of the porcelain on the denture. The thickness is uneven, and the porcelain powder is easy to fall off; however, during the porcelain coating process using a fluidized bed coating machine, the denture is always suspended in the airflow, and the temperature of the denture cannot be directly measured by the sensor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com