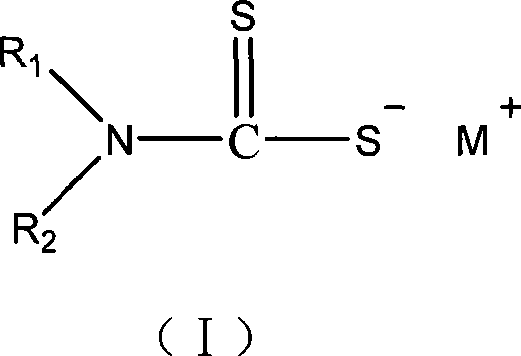

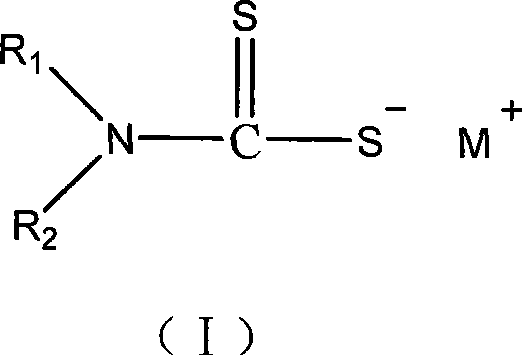

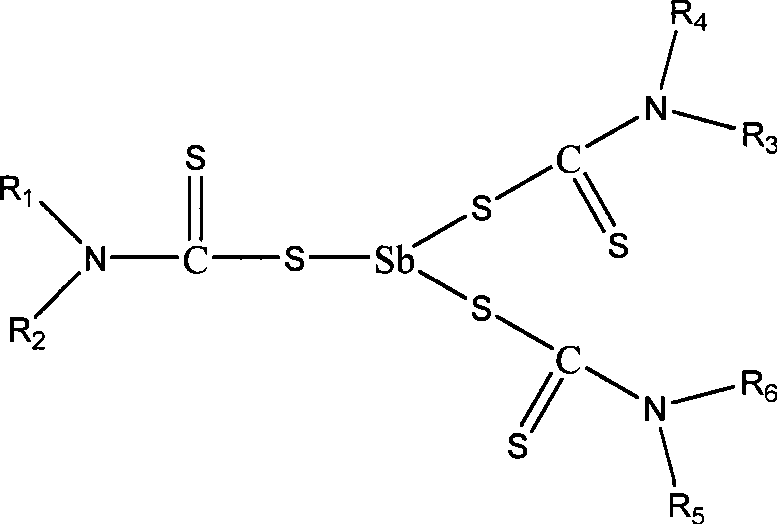

Method for preparing oil soluble antimony dithiocarbamate

A technology based on dithiocarbamic acid and dithioamine, which is applied in the field of preparation of oil-soluble antimony dithiocarbamate, which can solve the problems of difficult purification of products, equipment corrosion, high energy consumption, and low yield. , to achieve the effects of short production time, low production energy consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Antimony Dioctyldithioaminodithiocarbamate

[0028] Add 15.3g of sodium di-n-octyl dithiocarbamate and 50ml of water into a three-neck flask equipped with stirring, start stirring, and add the aqueous solution of antimony nitrate (7.275g) and manna alcohol (2.73g) dropwise within 15min , reacted at room temperature for 1 hour. 50ml of chloroform was added, the organic phase was separated, washed three times with water, dried with anhydrous sodium sulfate, filtered, and the solvent was removed by rotary evaporation to obtain 15.2g of light yellow powder. Yield 94.7%, antimony content (theoretical value: 11.38%): 11.7%.

Embodiment 2

[0030] Preparation of antimony dihexyldithiocarbamate

[0031] Add 12.7g of sodium di-n-hexyldithiocarbamate and 50ml of water into a three-necked flask equipped with stirring, start stirring, and add an aqueous solution of antimony nitrate (7.275g) and mannacol (2.73g) dropwise within 15min. React at room temperature for 1 hour. Add 50ml of chloroform, separate the organic phase, wash with water three times, add anhydrous sodium sulfate to dry, filter, remove the solvent by rotary evaporation, recrystallize with chloroform and ethanol, 12.72g of light yellow flaky crystals. Yield 93.9%, antimony content (theoretical value: 13.49%): 13.7%.

Embodiment 3

[0033] Preparation of Antimony Dibenzylaminodithiocarbamate

[0034] Add 13.8g of sodium dibenzyldithiocarbamate and 50ml of water into a three-necked flask equipped with stirring, start stirring, and add an aqueous solution of antimony nitrate (7.275g) and mannacol (2.73g) dropwise within 15min. React at room temperature for 1 hour. Add 50ml of chloroform, separate the organic phase, wash with water three times, add anhydrous sodium sulfate to dry, filter, remove the solvent by rotary evaporation, and recrystallize with chloroform and ethanol to obtain 13.32g of light yellow crystals. Yield 94.6%, antimony content (theoretical value: 12.97%): 13.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com