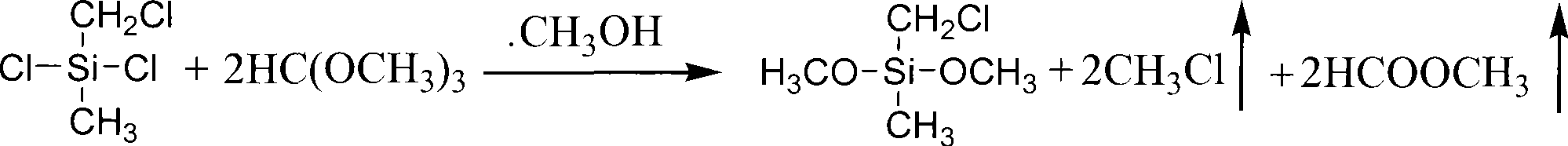

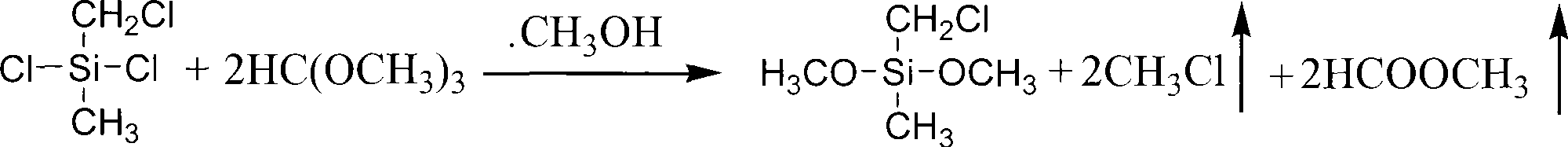

Preparation method of chloromethyl-methyl-dimethylsilane

A technology of chloromethylmethyldimethoxysilane and chloromethylmethyldichlorosilane, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc., and can solve the conditions Harshness, low reaction temperature, long reaction process cycle time, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

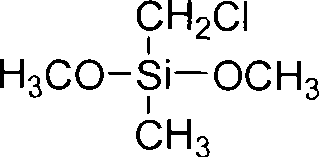

[0024] First, inject chloromethylmethyldichlorosilane (400mol) into the storage tank, then mix trimethyl orthoformate (800mol) and methanol (200mol) in the reaction kettle, and at 50°C, the chloromethyl Methyldichlorosilane was added to the reaction kettle for 1 hour; after atmospheric distillation, fractions were collected at 140-143°C to obtain 60.4 kg of chloromethylmethyldimethoxysilane with a yield of 98%. Purity 100% (GC). Chloromethane and methyl formate gases released during the reaction were collected by cryogenic cold traps.

Embodiment 2

[0026] First, chloromethylmethyldichlorosilane (51 liters) is injected into the storage tank, then trimethyl orthoformate (109 liters) and methanol (0.8 liters) are mixed in the reactor, and at 40 ° C, the Chloromethylmethyldichlorosilane was added to the reaction kettle for 4 hours; after atmospheric distillation, fractions were collected at 140-143°C to obtain 60 kg of chloromethylmethyldimethoxysilane with a yield of 97%, purity 99% (GC). Chloromethane and methyl formate gases released during the reaction were collected by cryogenic cold traps.

Embodiment 3

[0028] First, chloromethylmethyldichlorosilane (51 liters) is injected into the storage tank, then trimethyl orthoformate (91.5 liters) and methanol (3.2 liters) are mixed in the reactor, and at 90 ° C, the Chloromethylmethyldichlorosilane was added to the reaction kettle for 30 minutes; after atmospheric distillation, fractions were collected at 140-143°C to obtain 59 kg of chloromethylmethyldimethoxysilane with a yield of 96%, purity 100% (GC). Chloromethane and methyl formate gases released during the reaction were collected by cryogenic cold traps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com