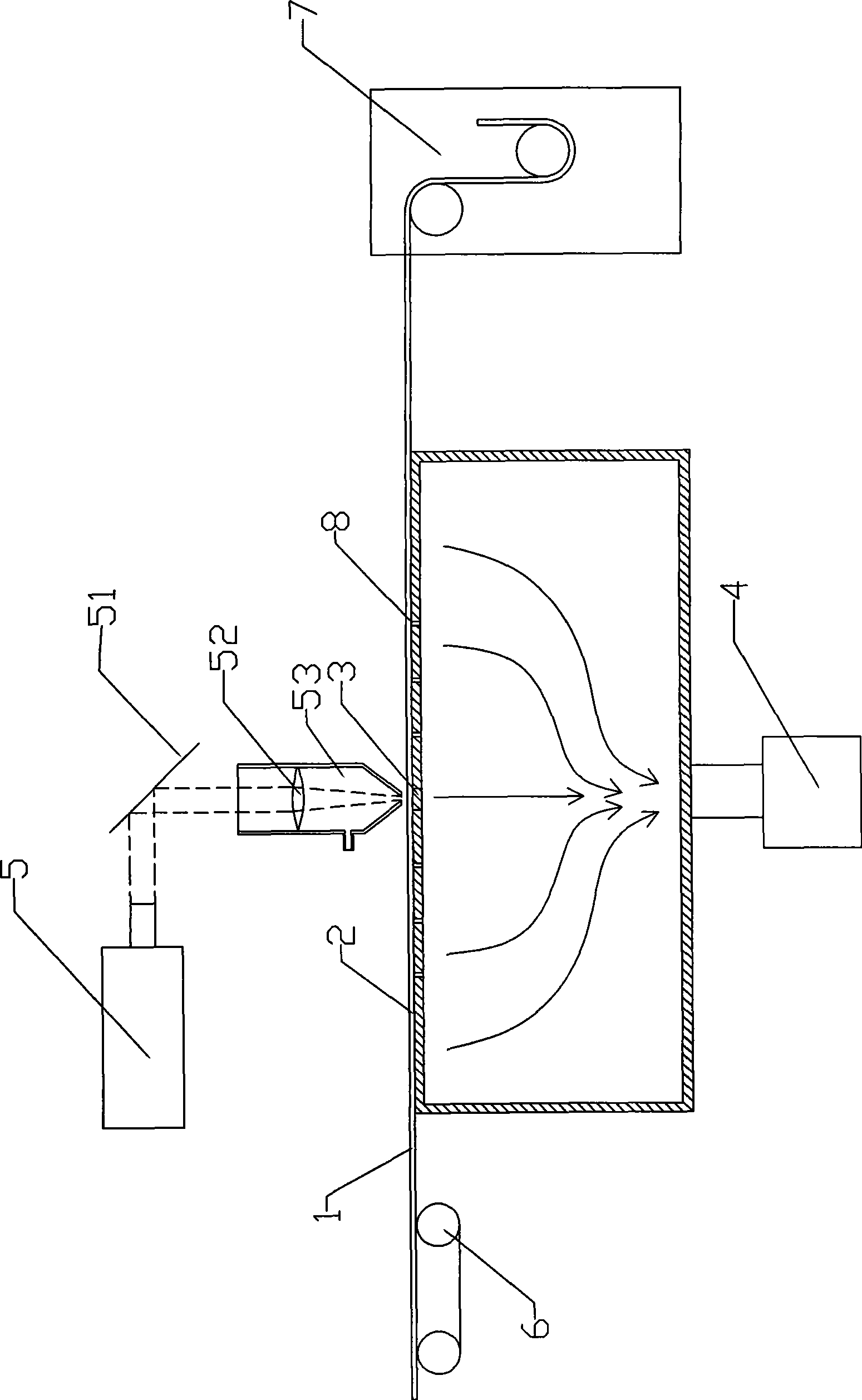

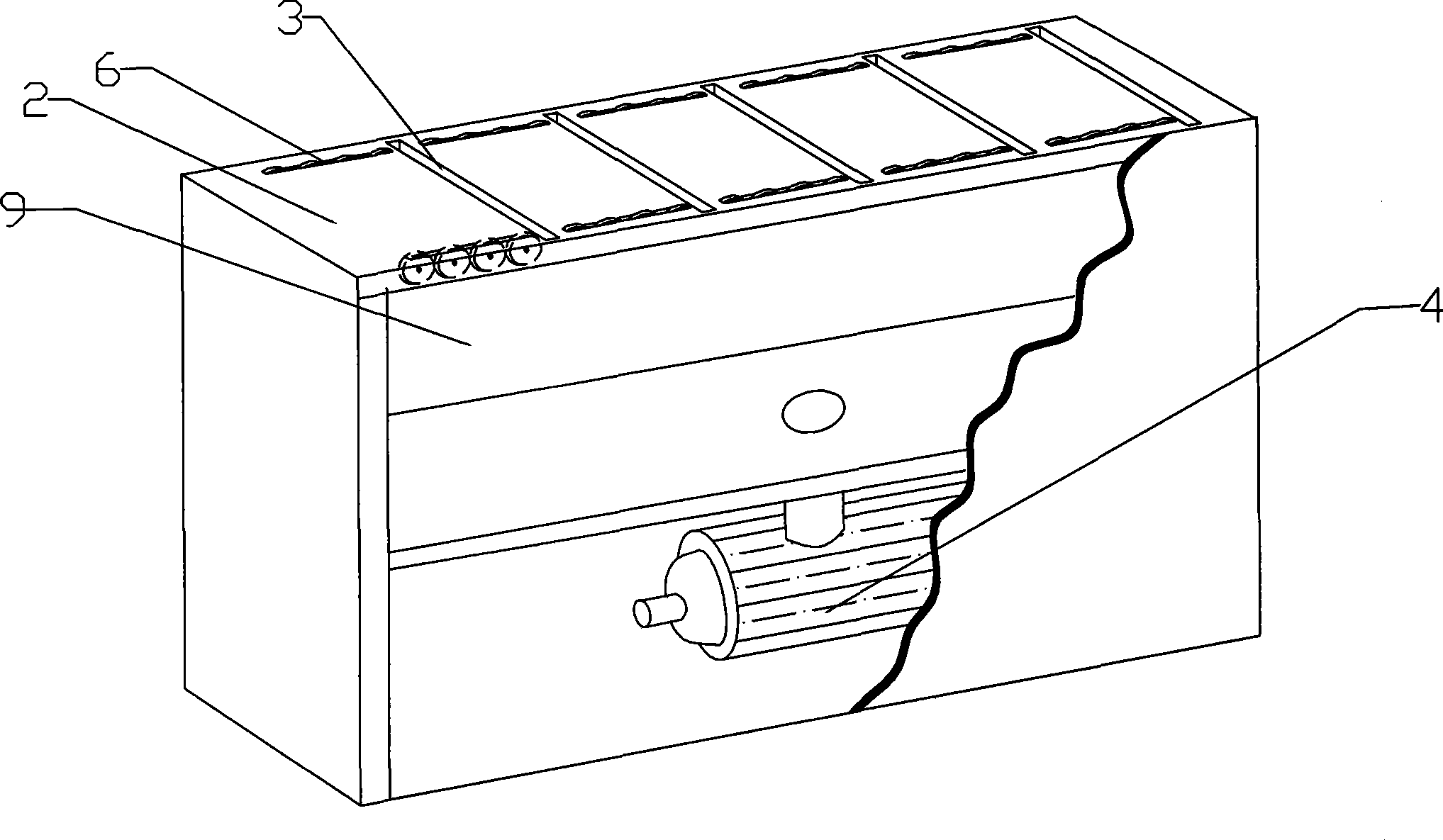

Laser cutting method of amorphous alloy strip steel rolled stock

An amorphous alloy, laser cutting technology, used in laser welding equipment, welding/cutting auxiliary equipment, metal processing equipment, etc., can solve the problems of strip damage, inability to process strip, affecting processing accuracy, etc., to achieve guaranteed results and accuracy, suitable for promotion and use, and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The amorphous alloy strip with a thickness of 0.03mm passes through the processing channel at a constant speed, the vacuum device is a vacuum pump, the ultimate vacuum can be obtained at 0.01Pa, and the pulse energy density is 1×10 5 w / cm 2 , The laser beam with a pulse width of 125ms cuts the amorphous alloy strip that is close to the working surface. The surface of the alloy strip obtained by cutting is smooth, the incision is uniform and burr-free, and all index parameters meet the requirements.

Embodiment 2

[0053] The amorphous alloy strip with a thickness of 0.05mm passes through the processing position at a constant speed. The vacuum device is a vacuum pump, and the ultimate vacuum can be obtained at 0.05Pa. The pulse energy density is 1×10 6 w / cm 2 , The laser beam with a pulse width of 200ms cuts the amorphous alloy strip that is close to the working surface. The surface of the alloy strip obtained by cutting is smooth, the incision is uniform and burr-free, and all index parameters meet the requirements.

Embodiment 3

[0055] The amorphous alloy strip with a thickness of 0.1mm passes through the processing position at a constant speed, the vacuum device is a vacuum pump, the ultimate vacuum can be obtained at 0.1Pa, and the pulse energy density is 1×10 8 w / cm 2 , The laser beam with a pulse width of 250ms cuts the amorphous alloy strip that is close to the working surface. The surface of the alloy strip obtained by cutting is smooth, the incision is uniform and burr-free, and all index parameters meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com