Control method for oxygen argon decarbonization converter end point temperature end point carbon

A converter end point, oxygen and argon decarburization technology, applied in the manufacture of converters, etc., can solve the problems of low degree of automation, unstable process, unfavorable converter maintenance, etc., and achieve the goals of increasing furnace life, strong portability and reducing blowing loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

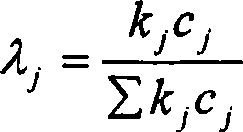

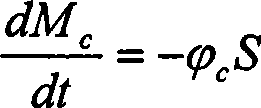

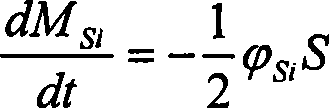

[0016] According to a kind of oxygen-argon decarburization converter endpoint temperature and endpoint carbon control method of the present invention, establish endpoint carbon and endpoint temperature control mathematical model, modeling is divided into the following steps:

[0017] (a) Read the C, Mn, Si, Cr, Ni, P chemical composition of molten steel in the AOD furnace under the initial conditions and the temperature of the initial furnace condition from the basic automation level L1.

[0018] (b) According to the data detected by L1 and the mathematical model of production process automation L2, the least square method is used to successively obtain the reaction rate constant Ki, the activity coefficient Fi of each component in the molten steel, and the reaction time of the slag liquid to the molten steel. Component mass transfer coefficient Ni, equilibrium constant Kco, Kcr 2 o 3 、Ksio 2 , according to the furnace condition, raw material composition and temperature cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com