Baiting processing method for end plate and side plate of fan coil pipe and its structure

A technology of a fan coil unit and a processing method, which is applied in the field of air conditioners, can solve the problems of wasting materials, the appearance of the equipment is not beautiful, and the sealing is unfavorable, and achieves the effects of reducing material loss, saving materials, and enhancing anti-deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

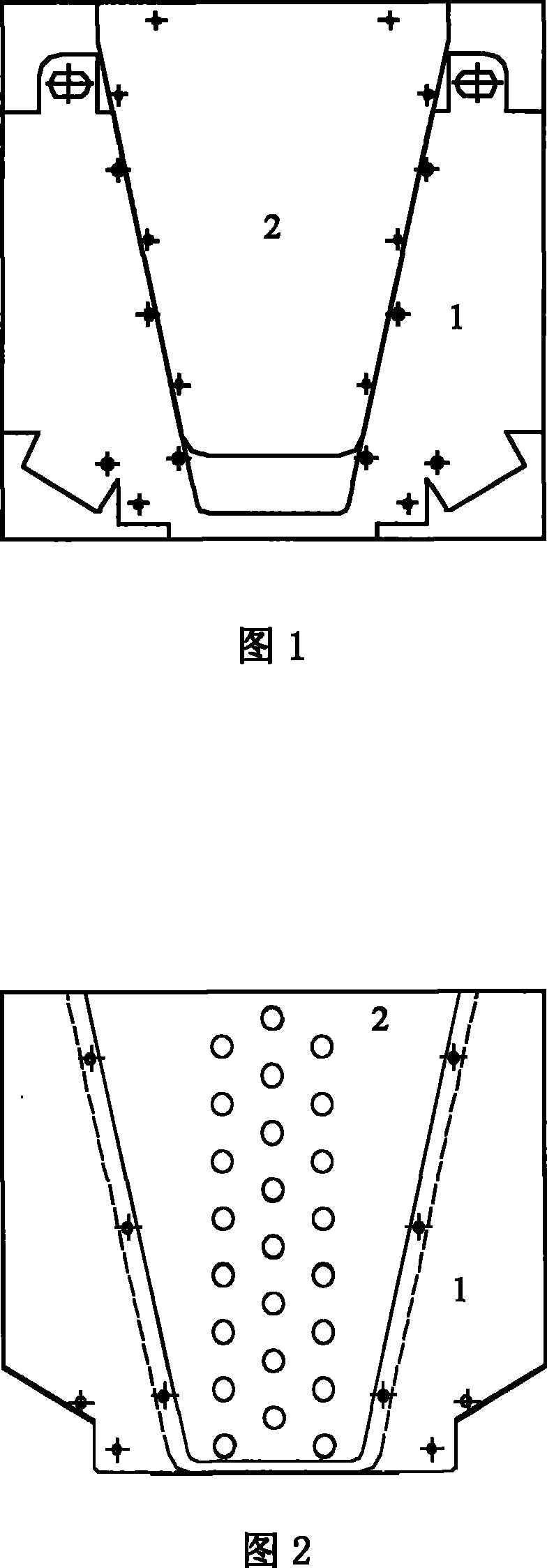

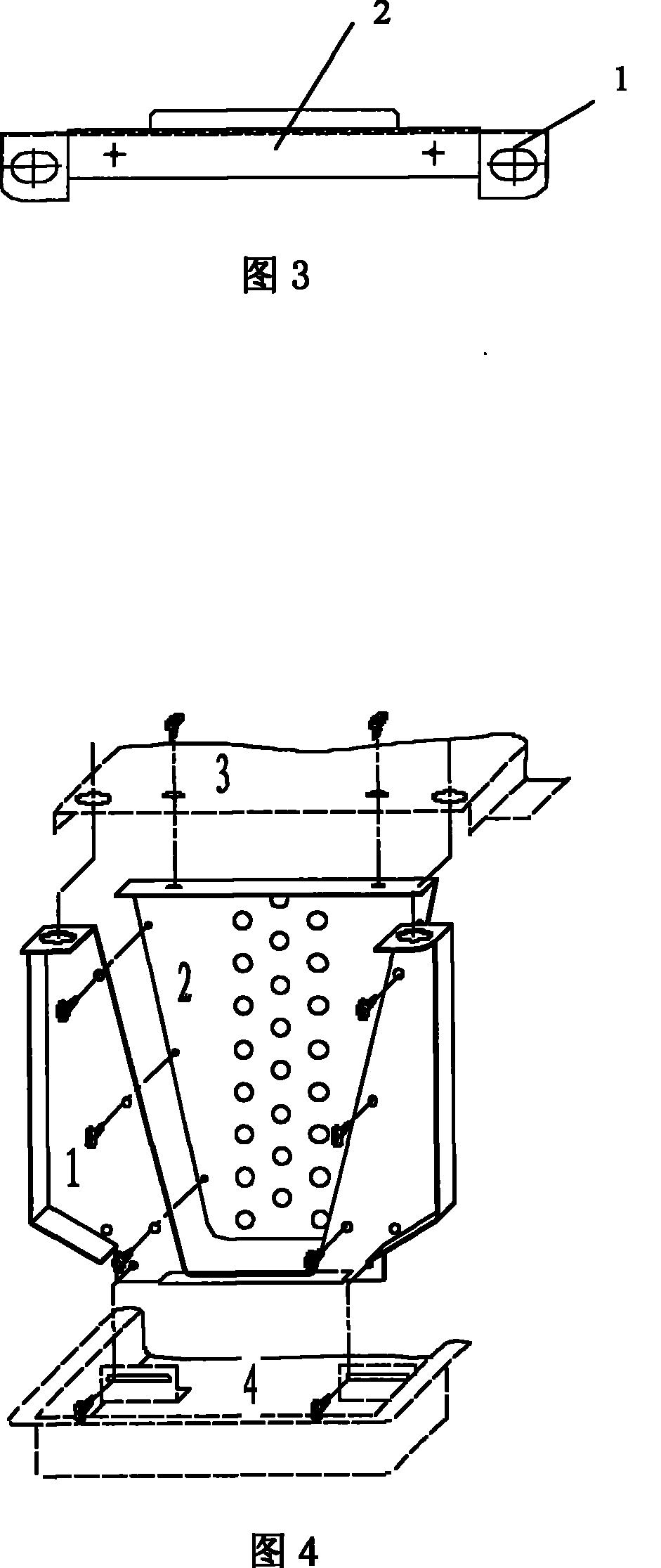

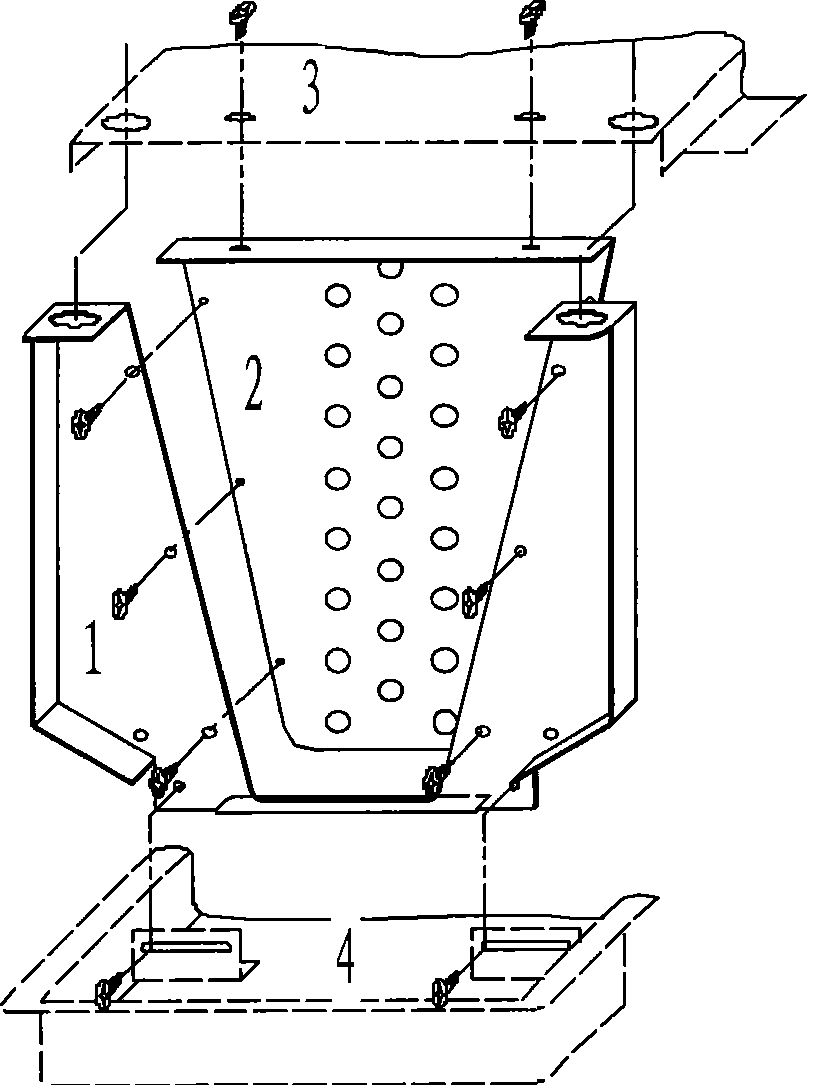

[0017] see Figure 1 to Figure 4 , The structure of the present invention includes the end plate 2 and the side plate 1 of the fan coil unit. The outer profile of the end plate 2 is an inverted trapezoid, and the top of the end plate 2 is turned inward. Holes connected with the side plate 1 and the top plate 3 of the fan coil unit are processed on the periphery and the flange of the end plate 2 . The outer contour of the side plate 1 is an inverted bottle neck shape, the top, side and neck of the side plate 1 are all turned inwards, and the bottom of the side plate 1 is folded outwards with outwards. The inner side of the side plate 1 after flanging and the upper and lower ends of the side plate 1 are respectively processed with connection holes with the end plate 2 , the top plate 3 of the fan coil unit and the condensed water tray 4 .

[0018] The blanking processing method step of end plate 2 and side plate 1 of the present invention is:

[0019] ①Cut a piece of rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com