Semi-volatile organic matter sampling technique in exhaust emission pipe

A kind of exhaust gas emission and semi-volatile technology, applied in sampling devices, preparation of samples for testing, etc., can solve the problems of collection, small molecular weight, unable to truly reflect and understand the amount and status of SVOC pollution, and achieve convenient sample extraction. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

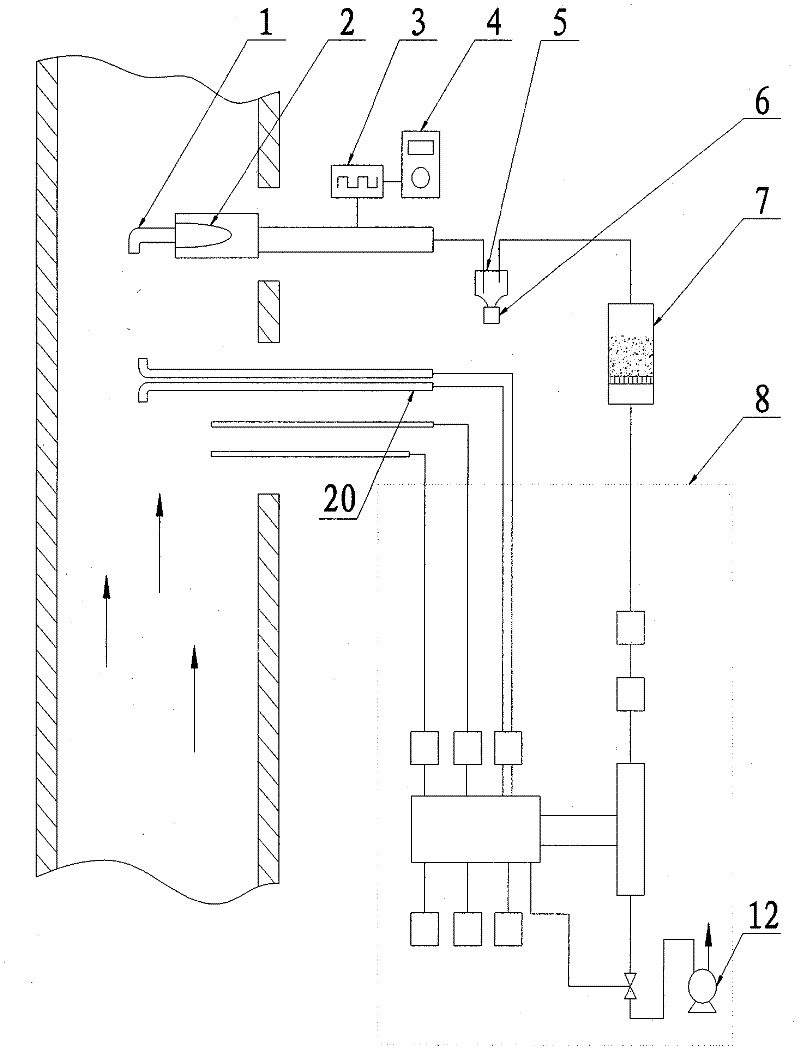

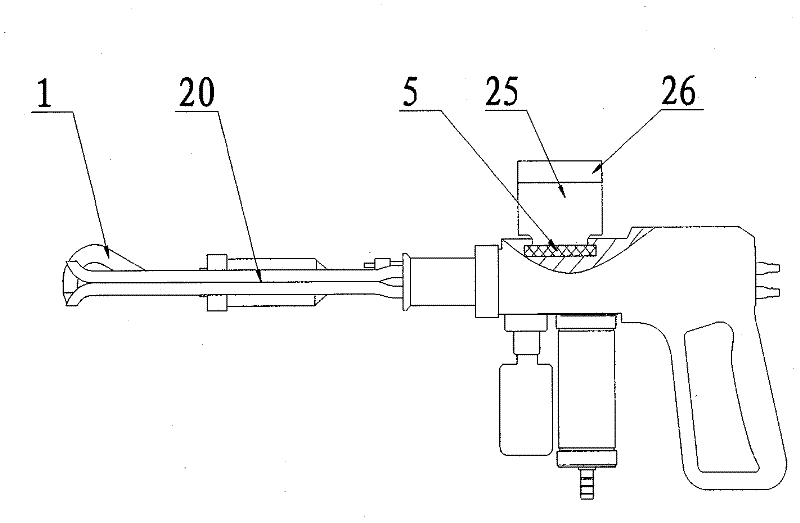

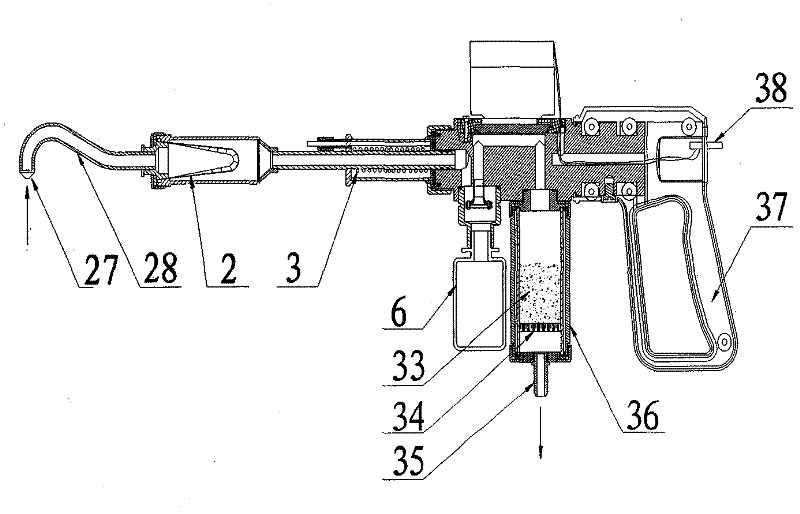

[0017] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, the sampling device designed according to the semi-volatile organic compound sampling method in the exhaust gas discharge pipeline of the present invention includes: a sampling tube 1, a pitot tube 20, a temperature sensor, a condensation device 5, a radiator 25, a fan 26, Sampling nozzle 27, filter cartridge 2, heating insulation tube 3, temperature controller 31, liquid collection bottle 6, adsorbent 33, adsorption tank 7, air outlet 35, outer cover 36, handle 37, power cord 38, adsorbent 33 is housed The adsorption tank 7 is connected in series in the sampling gas path. The adsorption tank 7 is a column made of glass, and its upper and lower ends are open. The orifice 34 that core is made, has many ventilation holes on the sand core, and orifice 34 separates adsorption tank 7 into two intervals, one of which is used for adorning adsorbent 33, and gas can pass through the interval and The orifice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com