Temperature fuse and method of manufacturing the same

A technology for thermal fuses and manufacturing methods, which is applied in fuse manufacturing, emergency protection devices, electrical components, etc., can solve the problems of high cost and large investment, and achieve the effects of good airtightness, thin product size, and stable fusing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

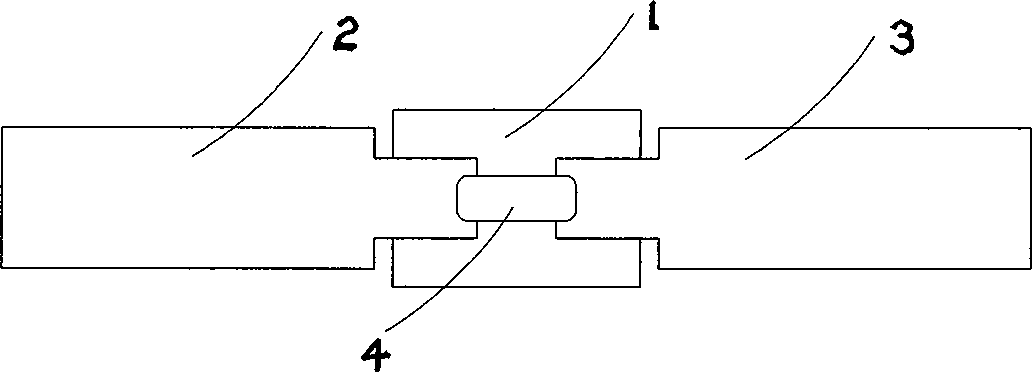

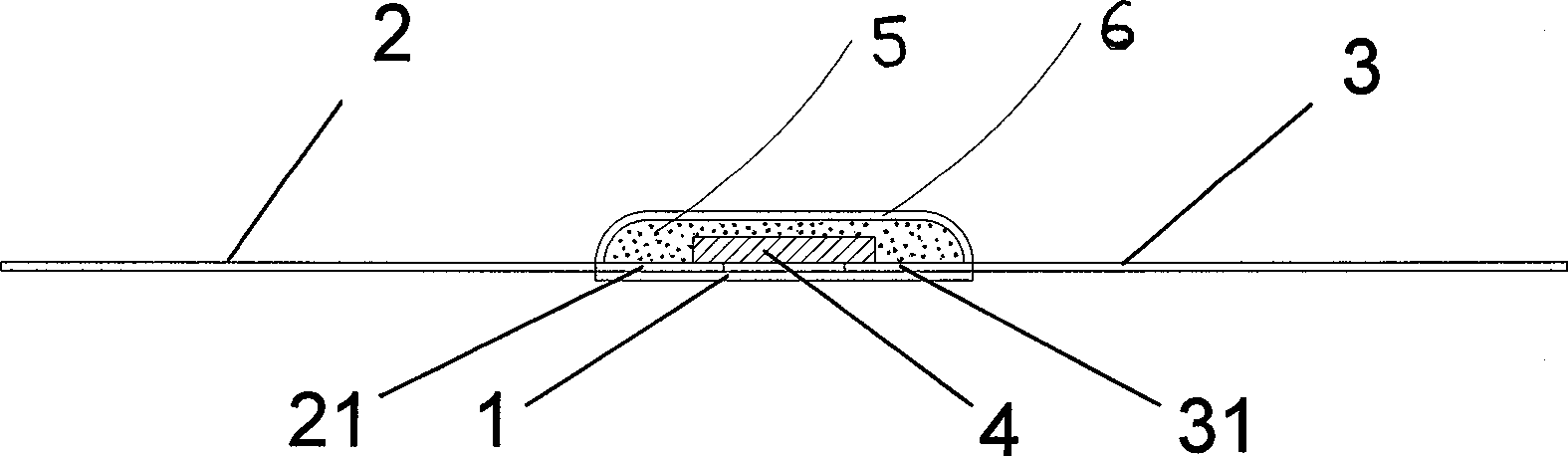

[0040] see figure 1 It is a schematic diagram of the partial composition structure of the thermal fuse of embodiment 1 and figure 2 As shown in the schematic diagram of the front view structure of the thermal fuse in Embodiment 1, a method for manufacturing a thermal fuse includes the following steps:

[0041] Stamping 0.1mm thick PBT film material into 4.5×3.2mm rectangular negative film 1;

[0042] Bond a pair of nickel metal electrodes 2 and 3 with a width of 1.4mm and a pair of 2.5×10mm on the top of the negative film 1. The nickel metal electrodes 2 and 3 are relatively arranged in a straight line and leave a distance of 0.5mm between the ends 21 and 31;

[0043] A 0.8×2mm fusible alloy 4 is welded between the two nickel metal electrodes 2 and 3 by heat welding;

[0044] Coating the flux 5 on the surface of the fusible alloy 4 by heating and dropping, covering the fusible alloy 4, and heating slightly to make the fusible alloy 4 flow and form naturally;

[0045] Add a...

Embodiment 2

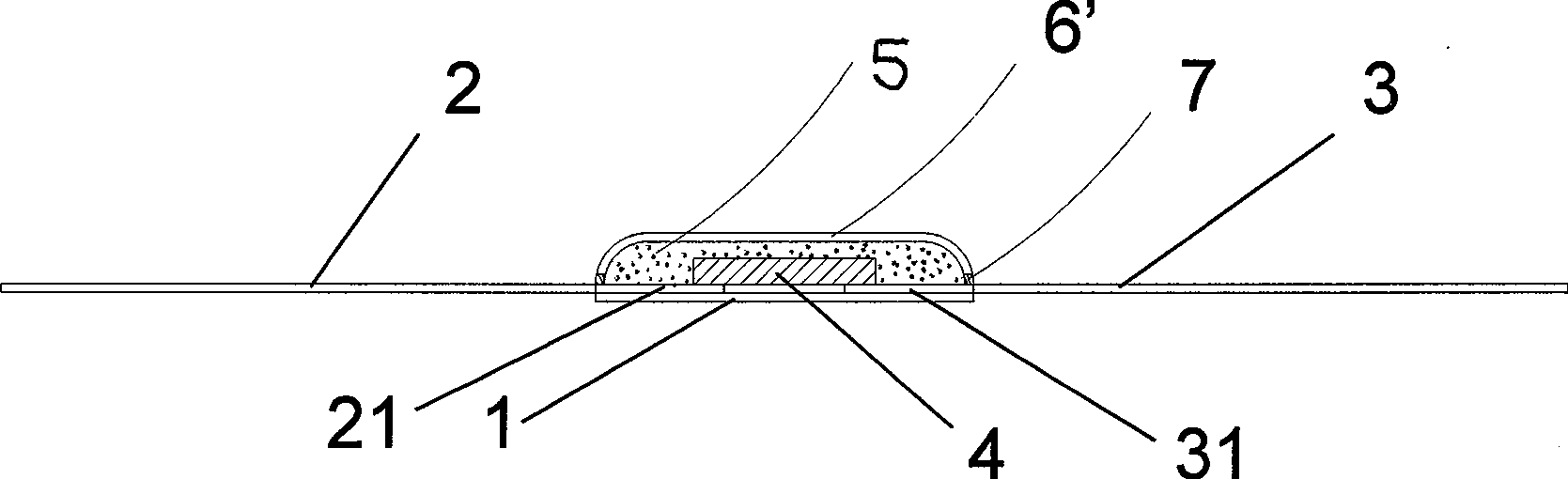

[0049] see image 3 As shown in the schematic diagram of the front view of the thermal fuse in Example 2, the 0.1mm thick PBT film material is stamped into a 4.5×3.2mm rectangular negative sheet 1;

[0050] Bond a pair of nickel metal electrodes 2 and 3 with a width of 1.4mm and a pair of 2.5×10mm on the top of the negative film 1. The nickel metal electrodes 2 and 3 are relatively arranged in a straight line and leave a distance of 0.5mm between the ends 21 and 31;

[0051] A 0.8×2mm fusible alloy 4 is welded between the two nickel metal electrodes 2 and 3 by heat welding;

[0052] Coating the flux 5 on the surface of the fusible alloy 4 by heating and dropping, covering the fusible alloy 4, and heating slightly to make the fusible alloy 4 flow and form naturally;

[0053] Add room temperature curing adhesive or light curing adhesive 6' dropwise above the flux 5 and allow it to flow naturally;

[0054] A ring-shaped upper cover sheet 7 is placed, and the upper cover sheet 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com