Automatic electric intensity tracing and control system

A technology of electric field strength and control system, applied in general control system, control/adjustment system, program control, etc., can solve problems such as increased labor intensity of staff, low production efficiency of manual operation, difficulty in product quality assurance, etc., to improve the market Competitiveness, ingenious design concept, and the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific examples.

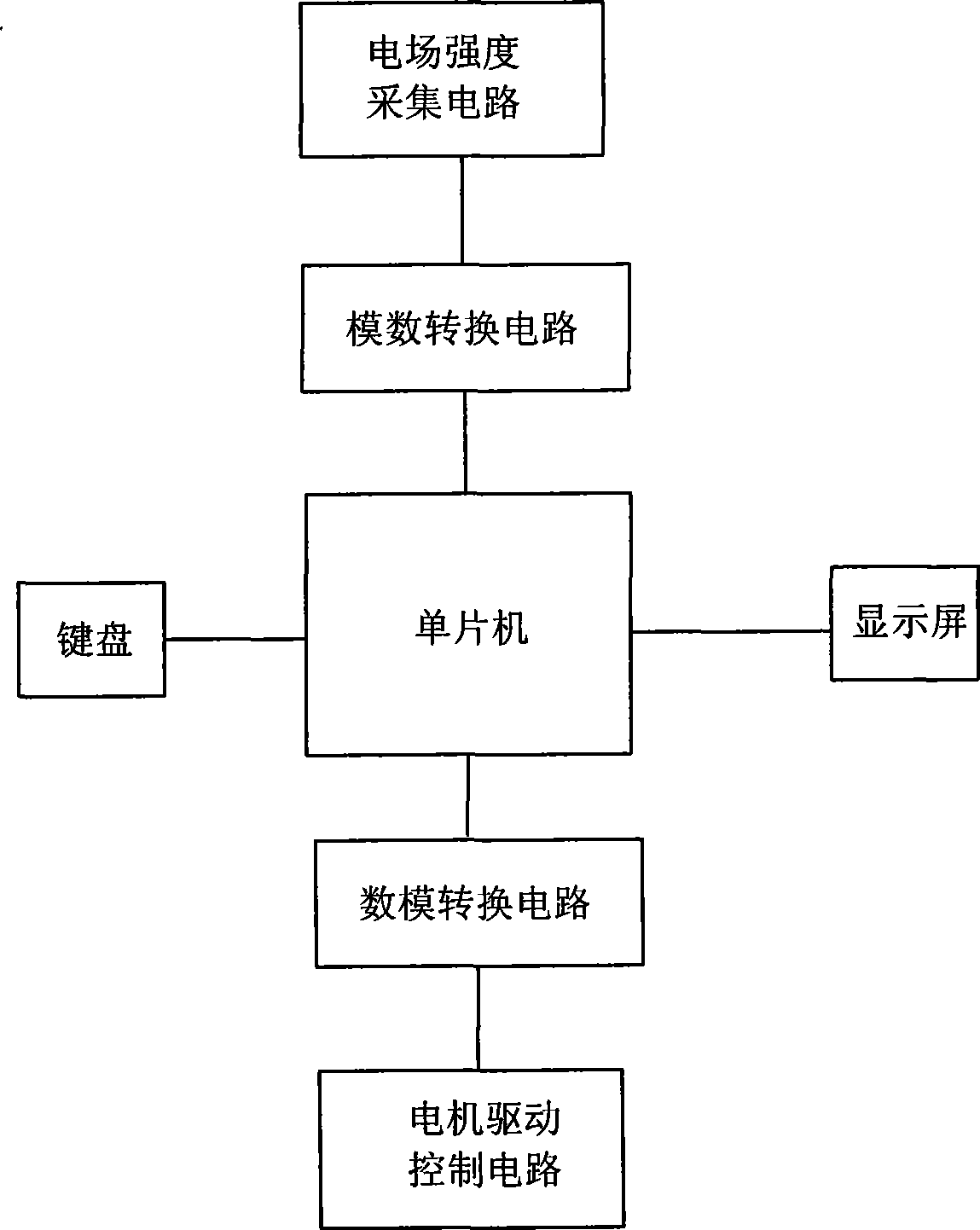

[0014] Such as figure 1 As shown, the electric field strength automatic tracking and control system is composed of single-chip microcomputer, electric field strength acquisition circuit, motor drive control circuit, analog-to-digital conversion circuit, digital-to-analog conversion circuit, keyboard and display screen, wherein the output terminal of single-chip microcomputer and analog-to-digital conversion circuit , the input end of the digital-to-analog conversion circuit, the keyboard and the display screen are all connected through the I / O interface, the input end of the analog-to-digital conversion circuit is connected to the output end of the electric field intensity acquisition circuit, and the output end of the digital-to-analog conversion circuit is connected to the motor drive connected to the control circuit. . In this embodiment, the electric field intensity acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com