Mixed solvent low-pressure fluid critical extract method

A technology of mixed solvents and extraction methods, applied in the direction of solid solvent extraction, etc., can solve the problems of large direct impact, large environmental pollution, high production cost, etc., and achieve the effects of reducing the loss of volatile substances, improving product purity, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

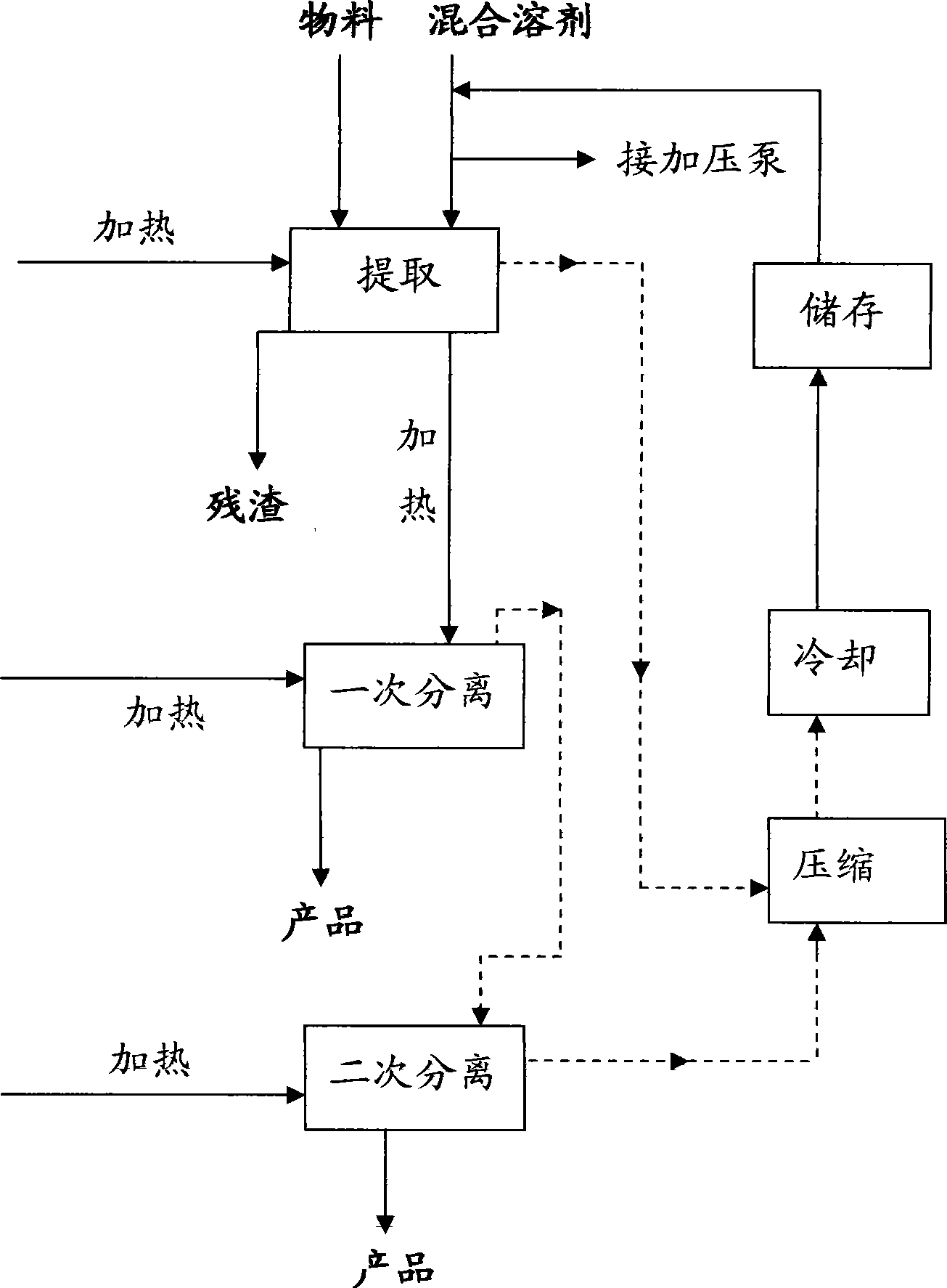

Image

Examples

Embodiment 1

[0023] Embodiment 1: extract lavender oil from lavender

[0024] ①Preparation

[0025] Clean the equipment and pipelines, confirm that the water, electricity, gas and other equipment are in a normal state of operation, and confirm that the valves are in the correct position;

[0026] ②Extraction

[0027] (A) material lavender is placed in the extraction tank with jacket, then airtight, extraction tank, separation tower and pipeline are evacuated to<-0.08Mpa and keep airtight;

[0028] (B) 95% by weight of 1,1,1,2-tetrafluoroethane and 5% by weight of n-butane are mixed uniformly as a mixed solvent, which is pressurized and pumped into the extraction tank, and simultaneously Heat hot water in the jacket, control the temperature of the extraction tank to 35°C, and the pressure to 2.5Mpa. The mixed solvent is in liquid state and contacts with the material to dissolve the active ingredients of the material. After maintaining this temperature and pressure for 10 minutes, the extr...

Embodiment 2

[0036] Embodiment 2: extract essential oil (star anise oil) from star anise

[0037] Step 1. and 4. are identical with embodiment 1, difference is:

[0038] ②Extraction

[0039] (A) place the material star anise in the extraction tank with jacket, then airtight, vacuumize the extraction tank, separation tower and pipeline to <-0.08Mpa and keep airtight;

[0040] (B) 92% by weight of 1,1,1,2-tetrafluoroethane and 8% by weight of n-butane are mixed uniformly as a mixed solvent, which is pressurized and pumped into the extraction tank, and simultaneously Heating with hot water in the jacket, control the temperature of the extraction tank at 40°C, and the pressure at 1.0-3.0Mpa. The mixed solvent is in liquid state and contacts with the material to dissolve the active ingredients of the material. After maintaining this temperature and pressure for 10 minutes, the extraction tank begins to emit The liquid of the active ingredient is sent to the heat exchanger to be heated while m...

Embodiment 3

[0043] Embodiment 3: extract alkane base oil from waste sludge oil

[0044] Step 1. and 4. are identical with embodiment 1, difference is:

[0045] ②Extraction

[0046] (A) Put the material waste sludge oil in an extraction tank with a jacket, and its filling capacity is 75-85% of the volume of the extraction tank, then seal it, and vacuumize the extraction tank, separation tower and pipeline to <-0.08 Mpa and keep airtight;

[0047] (B) 85% by weight of 1,1,1,2-tetrafluoroethane and 15% by weight of n-butane are mixed uniformly as a mixed solvent, and it is pressurized and pumped into the extraction tank, and the stirring is started Mix the mixed solvent and waste sludge oil evenly, and heat the jacket with hot water at the same time. Control the temperature of the extraction tank at 75°C and the pressure at 1.0-3.5Mpa. The mixed solvent is in a liquid state and contacts with the material to dissolve the active ingredients of the material. Keep this After 10 minutes of tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com