Method for preparing antioxidated superfine copper powder

An anti-oxidation technology of ultra-fine copper powder, which is applied in the field of preparation of anti-oxidation ultra-fine copper powder, can solve the problems of poor anti-oxidation performance of copper powder, difficulty in industrial application, and difficulty in controlling the particle size of copper powder, so as to improve anti-oxidation Performance, improved shape and particle size distribution, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

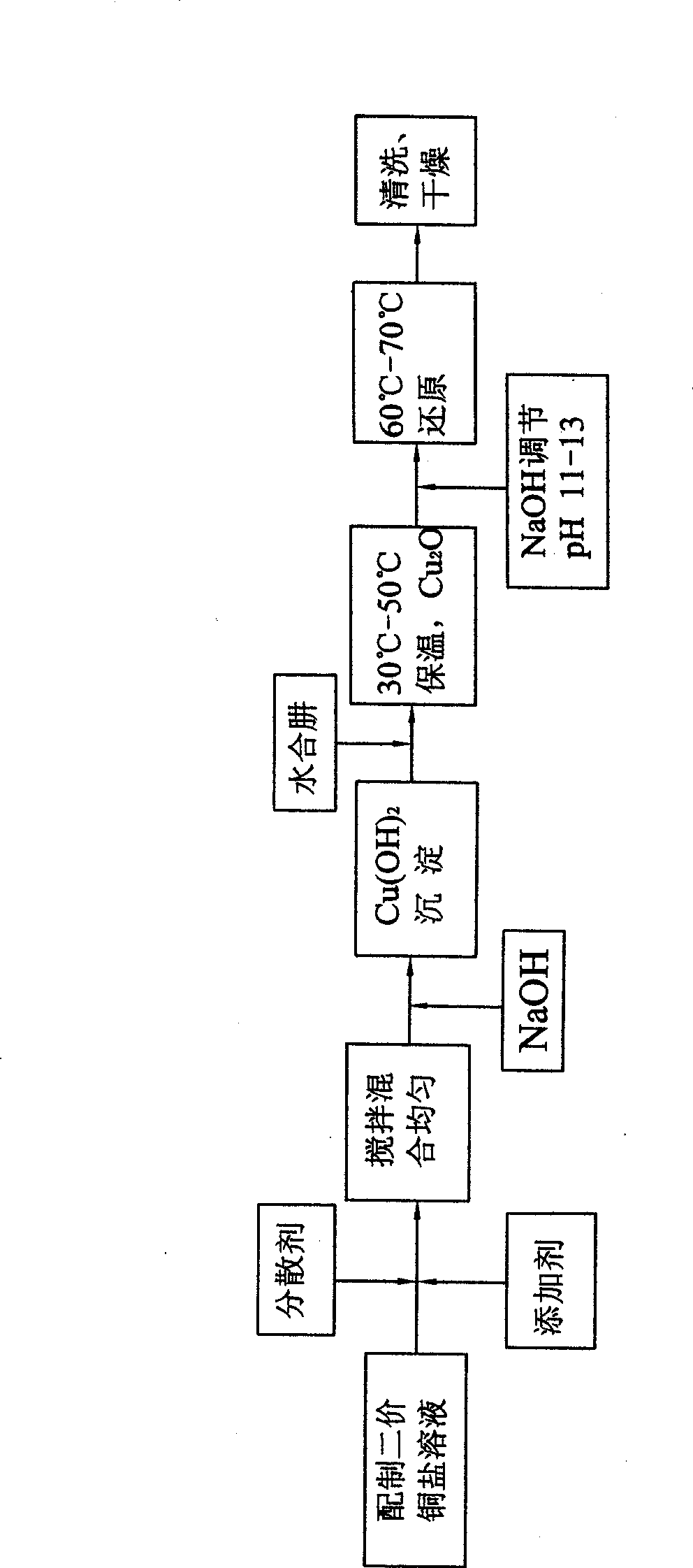

Method used

Image

Examples

Embodiment 1

[0028] 100ml of copper sulfate solution with a concentration of 0.02mol / L and 8ml of 20% NaOH solution were prepared respectively. in CuSO 4 Sodium dodecylbenzene sulfonate was added into the solution, fully dissolved, and its concentration reached 0.1g / L. Then add 2,2'-bipyridine so that its concentration is 10mg / L. Slowly add NaOH solution to CuSO under vigorous stirring at 300r / min 4 solution, making Cu 2+ The precipitate is light blue Cu(OH) 2 jelly. Then slowly add 0.003mol of hydrazine hydrate, the reaction proceeds vigorously, a large number of bubbles are generated, and the precipitate turns into an orange suspension. Thereafter, the reaction was incubated in two stages. In the first stage, the temperature of the suspension was raised to 30°C, and the stirring was continued until the color of the precipitate turned orange-red. Then carry out the second-stage reaction, first adjust the pH of the suspension with 20% NaOH to keep it at 11-12, raise the temperature ...

Embodiment 2

[0031] Prepare 100 ml of copper sulfate solution with a concentration of 0.1 mol / L and 40 ml of 20% NaOH solution respectively. in CuSO 4 Sodium dodecylbenzene sulfonate was added into the solution, fully dissolved, and its concentration reached 0.5g / L. Then add 2,2'-bipyridine so that its concentration is 30mg / L. Slowly add NaOH solution to CuSO under vigorous stirring at 300r / min 4 solution, making Cu 2+ Precipitate as Cu(OH) 2jelly. Then slowly add 0.02mol of hydrazine hydrate, the reaction proceeds vigorously, a large number of bubbles are generated, and the precipitate turns into an orange suspension. Thereafter, the reaction was incubated in two stages. In the first stage, the temperature of the suspension was raised to 40°C, and the stirring was continued until the color of the precipitate turned orange-red. Then carry out the second-stage reaction, first adjust the pH of the suspension with 20% NaOH to keep it at 12-13, raise the temperature to 60°C and keep it ...

Embodiment 3

[0034] 100ml of copper sulfate solution with a concentration of 0.2mol / L and 80ml of 20% NaOH solution were prepared respectively. in CuSO 4 Add PVP into the solution, fully dissolve, and make its concentration reach 1.0g / L. Then add 2,2'-bipyridine so that its concentration is 50mg / L. Slowly add NaOH solution to CuSO under vigorous stirring at 300r / min 4 solution, making Cu 2+ Precipitate as Cu(OH) 2 jelly. Then slowly add 0.05 mol of hydrazine hydrate, the reaction proceeds vigorously, a large number of bubbles are generated, and the precipitate turns into an orange suspension. Thereafter, the reaction was incubated in two stages. In the first stage, the temperature of the suspension was raised to 30°C, and the stirring was continued until the color of the precipitate turned orange-red. Then carry out the second-stage reaction, first adjust the pH of the suspension with 20% NaOH to keep it at 11-12, raise the temperature to 70°C and keep it warm until the bubbles gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com