Arc discharge type capacitance energy storage stud welding machine

A capacitor energy storage, stud welding machine technology, applied in arc welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of automatic welding, small charging range, high failure rate, and achieve good welding quality and equipment failure rate. drop, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

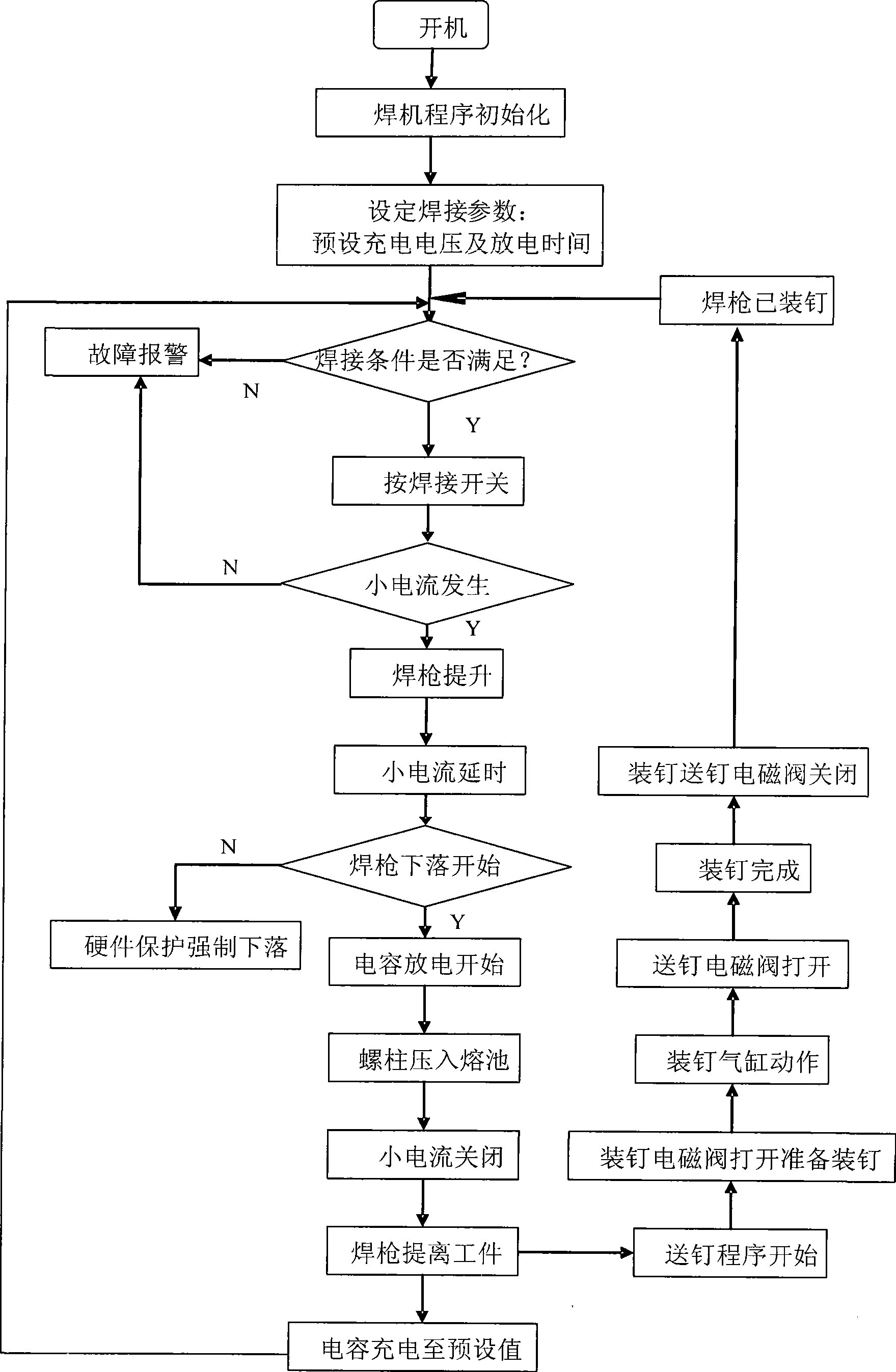

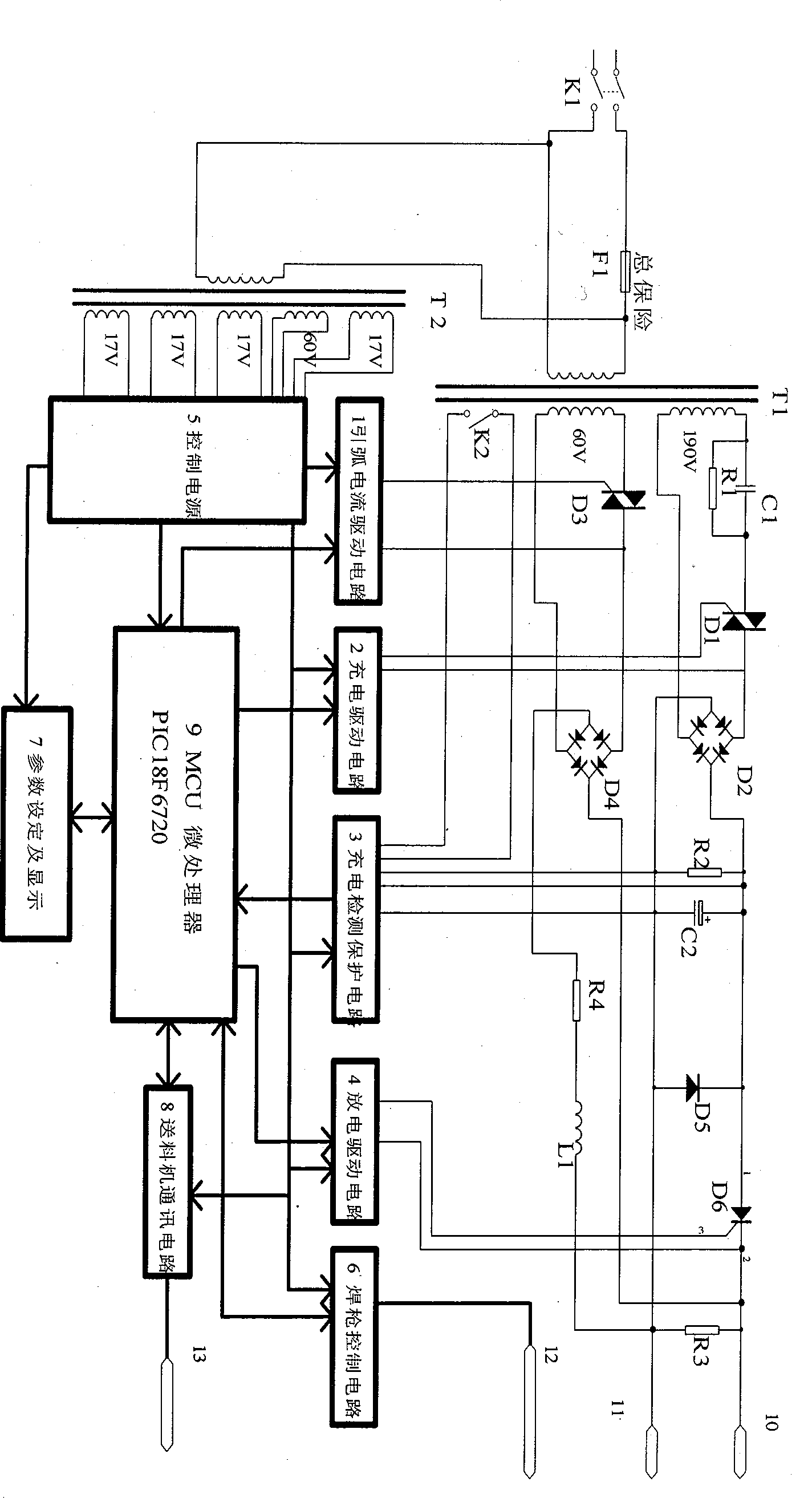

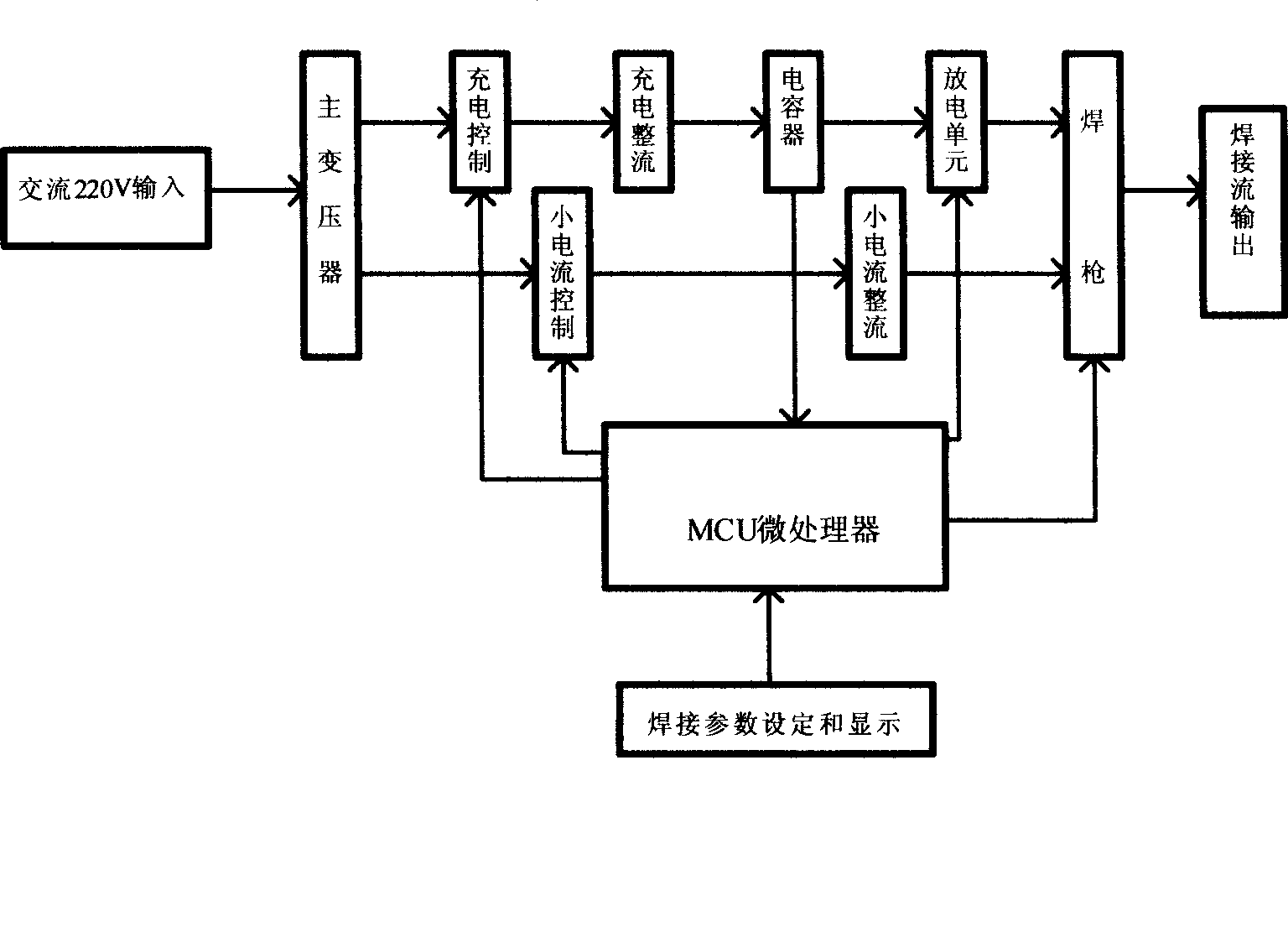

[0022] The working principle of the embodiment of the drawn arc capacitor energy storage stud welding machine of the present invention is as follows Figure 1 to Figure 4 shown.

[0023] The 220V power supply is connected to transformers T1 and T2 after passing through switch K1 and series fuse F1. T1 is a working transformer and T2 is a control power transformer. T1 turns the 220V power supply into AC190V charging power supply and AC60V arc ignition power supply. Transformer T2 provides control power supply to the MCU (MCU model is PIC18F6420) control board and main control board. The charging voltage range is 40V-200V.

[0024] The welding main circuit includes charging rectifier bridge D2, charging thyristor (triac) D1, energy storage capacitor (capacitor bank) C2, discharging thyristor D6 and absorbing diode D5. Compensation capacitor C1, charging thyristor (bidirectional thyristor) D1, terminals 1 and 3 of charging rectifier bridge D2 are connected in series to the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com