Method for gas-phase growth of carbon fibre

A technology of vapor phase growth and carbon fiber, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems such as the difficulty in optimizing the ratio of catalysts to hydrocarbons, the existence of catalyst particles in nanoscale form, and the uneven distribution of iron particles, etc., to achieve improved Oriented reactivity, easy vapor phase growth of carbon fibers, and reduced activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

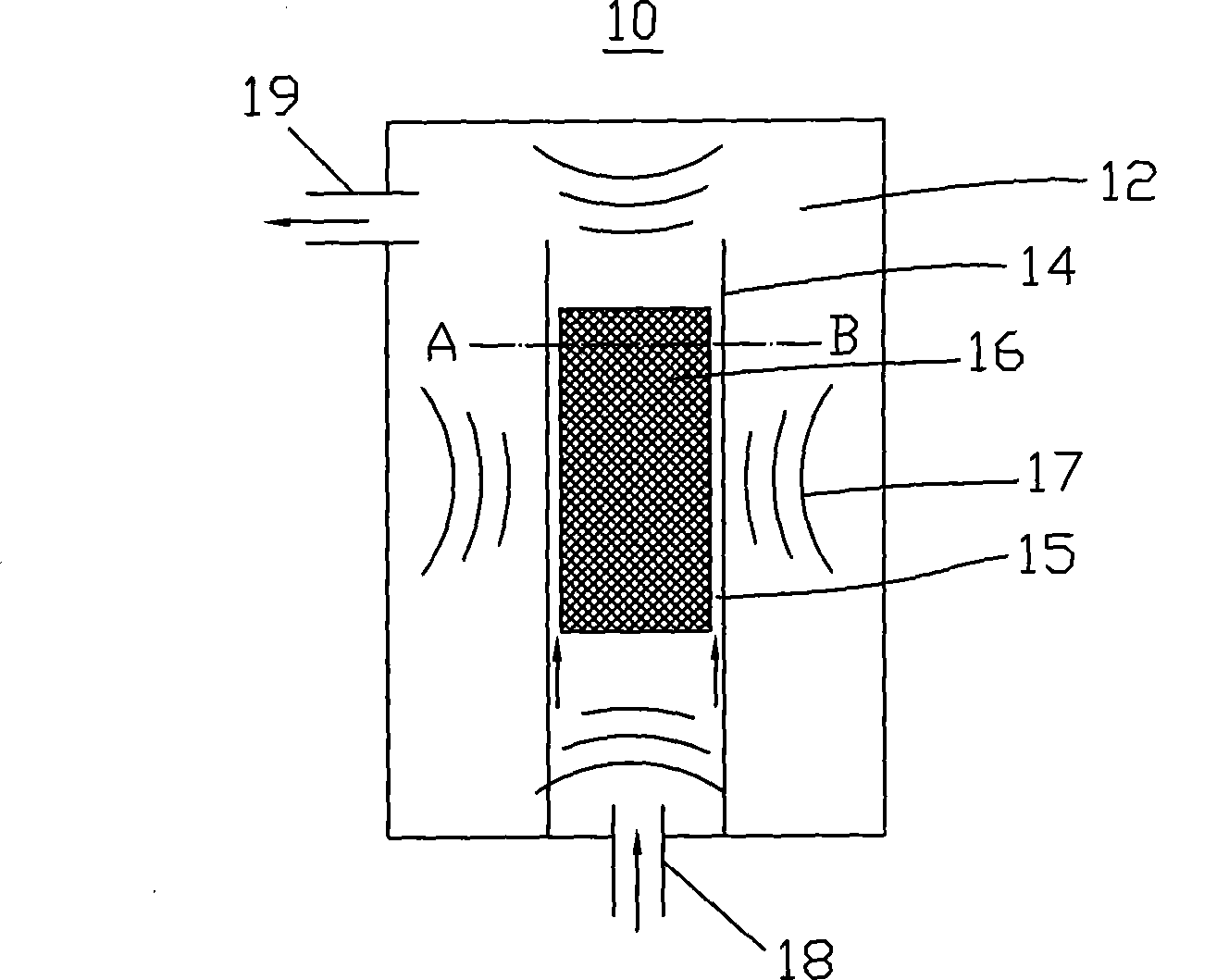

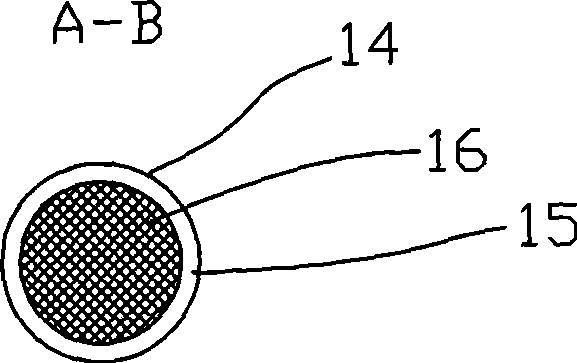

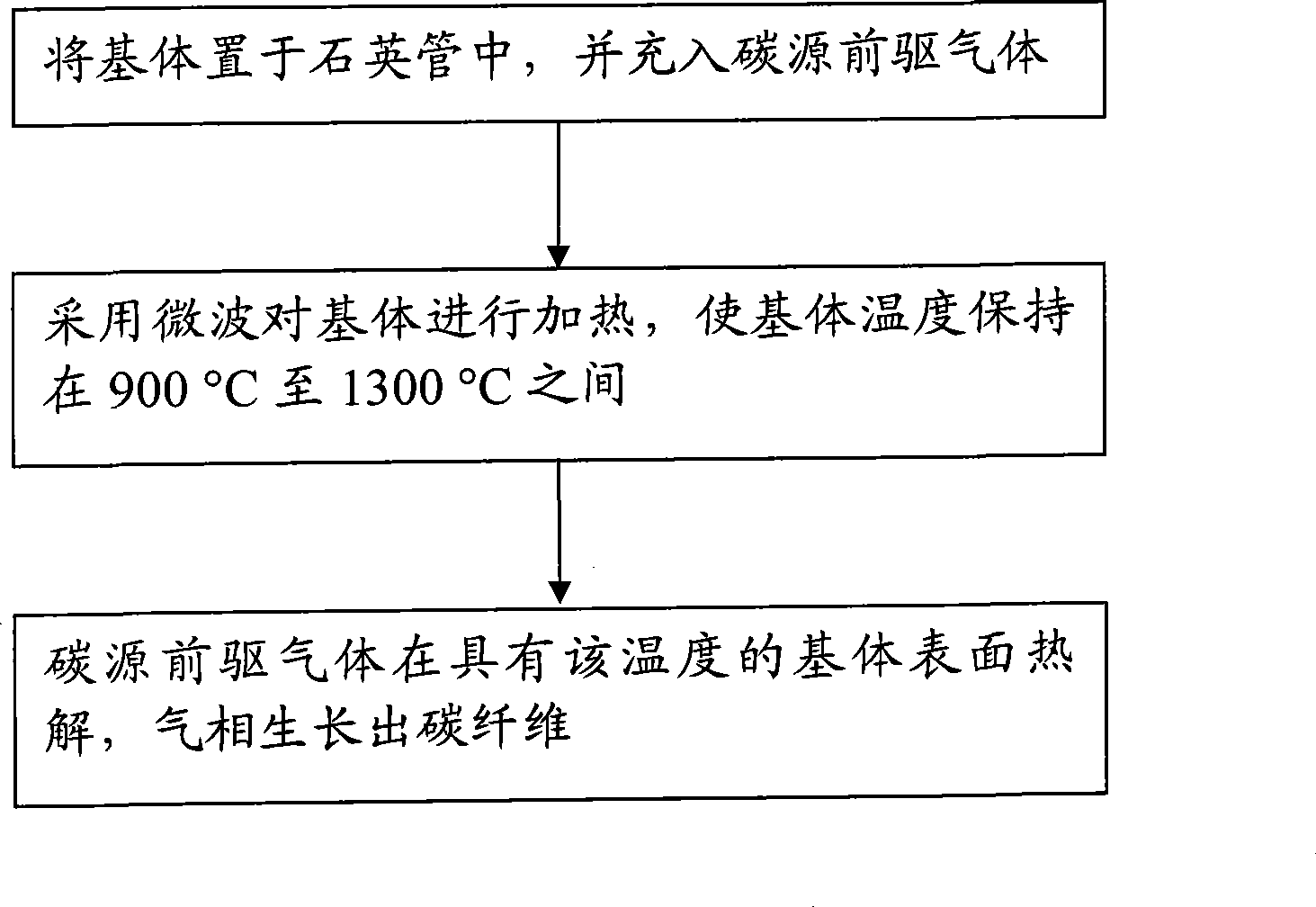

[0028] like figure 1 As shown, the substrate 16 is placed in the quartz tube 14 first, and the gap 15 between the substrate 16 and the quartz tube 14 is filled with carbon source precursor gas. In this embodiment, a substrate made of alumina is used, methane gas is the carbon source precursor gas, nitrogen gas is the carrier gas and diluent, and their mixed gas is passed through the inlet 18, and the residence time of the gas is 0.5s. The microwave source forms the microwave 17 to heat the substrate 16, and the heating reaches the pyrolysis temperature of the precursor, that is, methane gas. The temperature is maintained at 1300°C. After 1 hour of pyrolysis deposition, carbon fibers can be produced, as Figure 4 As shown, the carbon fibers are in the form of an array.

Embodiment 2

[0030] like figure 1 As shown, the substrate 16 is placed in the quartz tube 14 first, and the gap 15 between the substrate 16 and the quartz tube 14 is filled with carbon source precursor gas. In this embodiment, a substrate made of alumina is used, propylene gas is used as the carbon source precursor, nitrogen is used as the carrier gas and diluent, and their mixed gas is introduced from the inlet, and the residence time of the gas is 0.3s. The substrate is heated by a microwave source until it reaches the pyrolysis temperature of the precursor, and the temperature is maintained at 1100°C. After 1 hour of pyrolysis deposition, the following Figure 4 Carbon fiber shown.

Embodiment 3

[0032] like figure 1 As shown, the substrate 16 is placed in the quartz tube 14 first, and the gap 15 between the substrate 16 and the quartz tube 14 is filled with carbon source precursor gas. In this embodiment, a substrate made of alumina is used, acetylene gas is used as the carbon source precursor, nitrogen is used as the carrier gas and diluent, and their mixed gas is introduced from the inlet, and the residence time of the gas is 0.1s. The substrate is heated by a microwave source until it reaches the pyrolysis temperature of the precursor, and the temperature is maintained at 900°C. After 1 hour of pyrolysis deposition, the following Figure 4 Carbon fiber shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com