Ultra-high pressure intelligent pressure transmitter

An ultra-high pressure, transmitter technology, applied in the measurement of fluid pressure, measurement device, fluid pressure measurement by changing ohmic resistance, etc., can solve the problems of short service life, low test accuracy, low output signal, etc. Various properties, the effect of improving tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

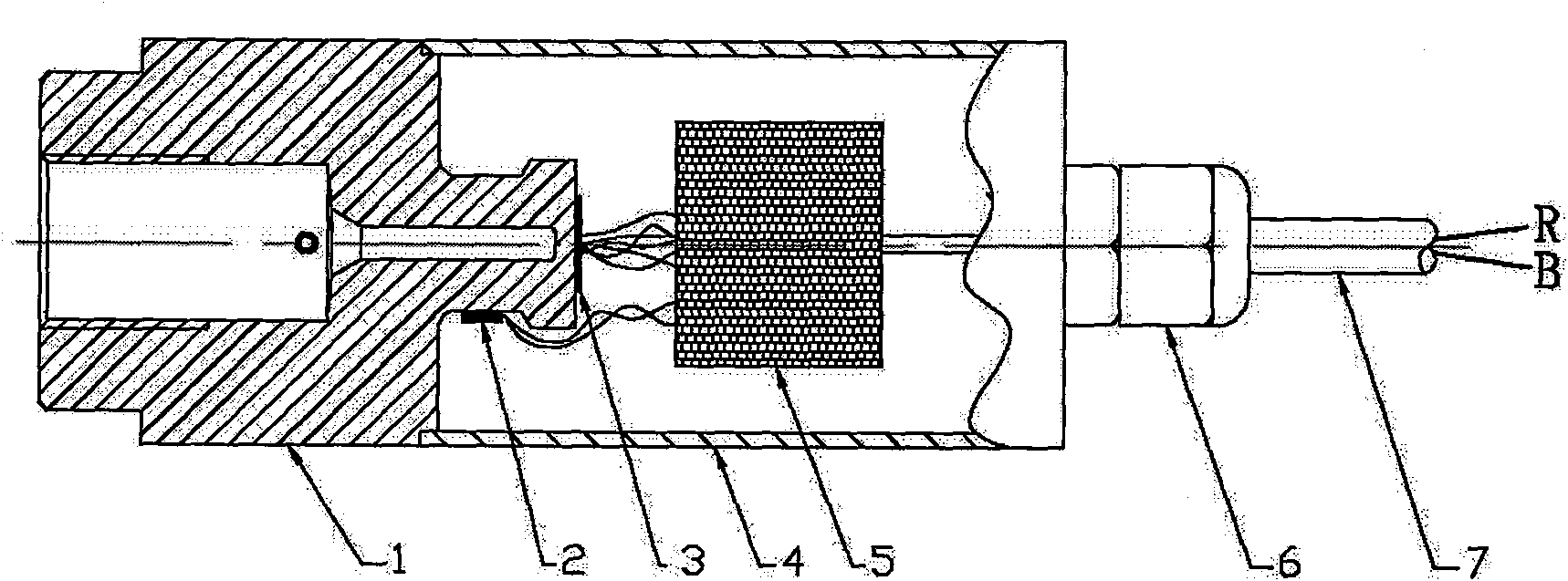

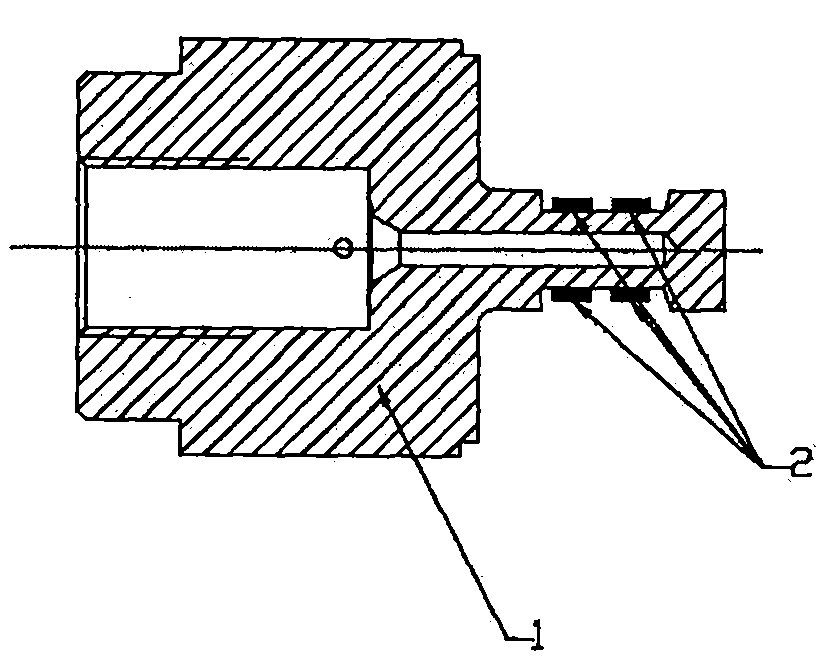

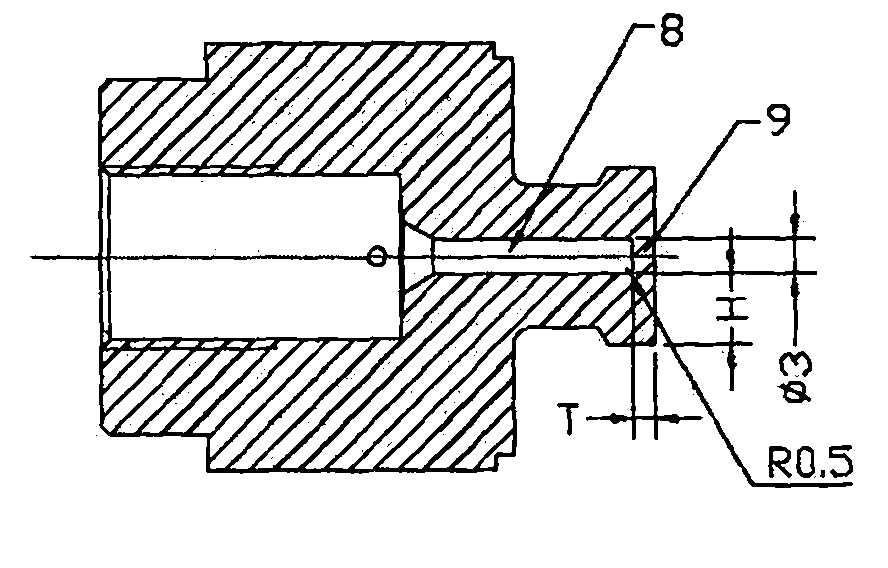

[0017] Such as figure 1 , image 3 As shown, processing in the design of the flat diaphragm pressure sensitive element 1 is the key to the implementation of the present invention. The processing of the elastic flat diaphragm 9 needs to ensure the flatness of the elastic flat diaphragm at the bottom of the pressure tube hole 8 and control the elasticity. The thickness of the flat diaphragm T, the value of T is determined by the size of the pressure to be measured, the higher the range, the larger the T, the value of the invention is 1.50mm≤T≤3.00mm, and the thickness error is controlled within 0.01mm; The parallelism of the control plane diaphragm, the allowable error is within the range of 0.005mm; it is necessary to ensure that there is a transition arc surface with a radius of R at the junction of the pressure pipe hole 8 and the bottom plane. The size of R is determined by the measured pressure Determined by the size, the value of the transition arc surface of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com