High-temperature erosion abrasion test device and method

A test device and erosion technology, applied in the field of material wear, corrosion and protection, to shorten the test cycle, accurate test data, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

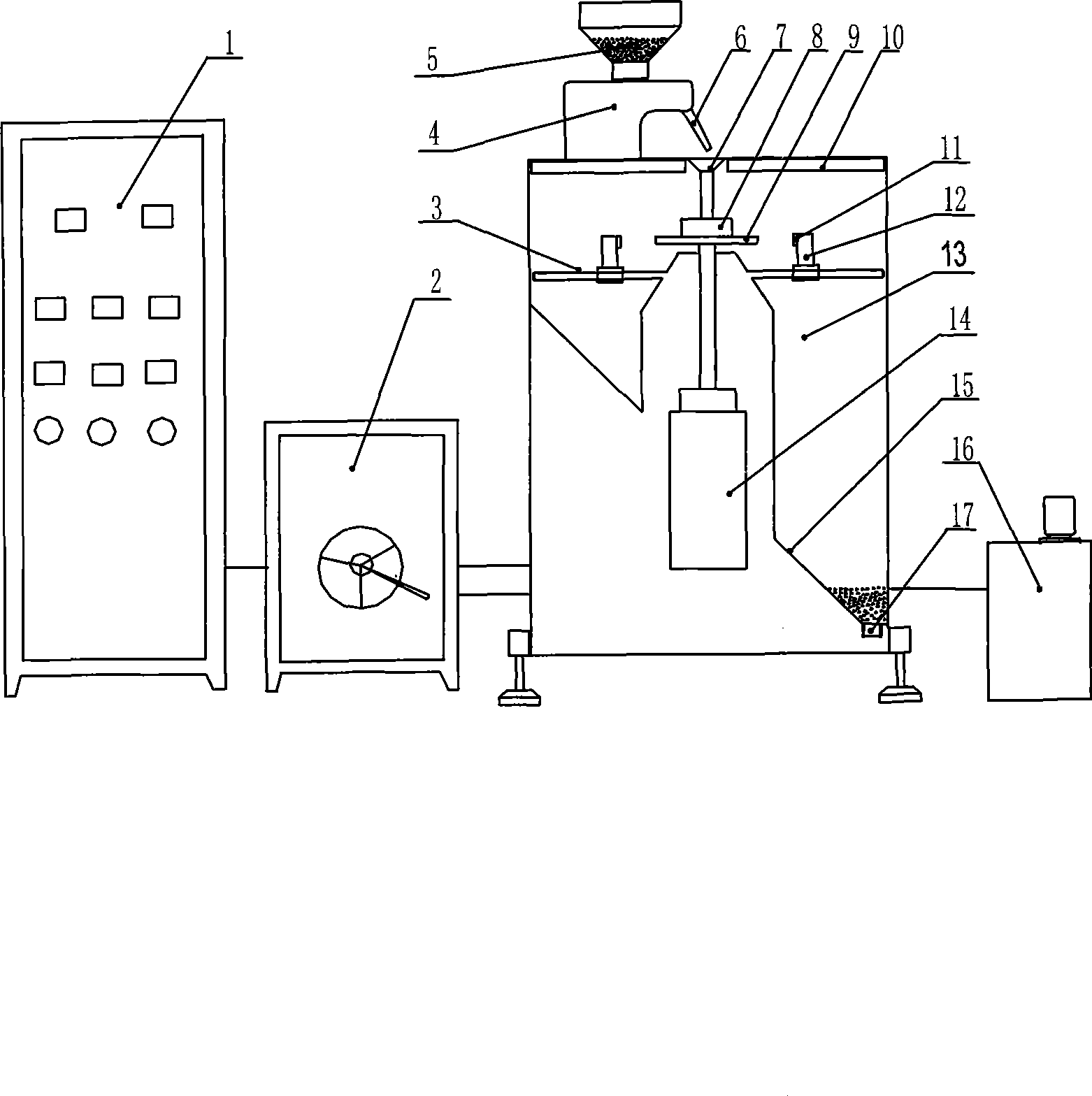

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] As shown in Figure 1, the present embodiment includes an erosion box 13, a sand feeder 4, and a funnel 7 arranged in the erosion box 13, a sand sub-pan 8, a sand rejection pan 9, a motor 14, a support 3 and electrode 12. Among them, the sand feeder 4 is arranged on the box cover 10 above the erosion box 13, the lower port of the shakeout tank 6 is aligned with the funnel mouth 7, and the sand grains 5 are transported to the shakeout tank 6 by a conveyor belt, and along the funnel 7 It is transported to the sand distribution tray 8, and then thrown out from the four sand outlet channels of the sand rejection tray 9, hits the surface of the sample 11, and finally passes through the sand slide plate 15 and is collected at the sand outlet 17. The sample 11 is installed on the electrode 12 fixed on the bracket 3 , the electrode 12 is connected with the heating power sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com