Digitized monitoring system for tobacco leaf baking

A monitoring system and tobacco leaf technology, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve the problem of ignoring the dynamic changes in the moisture content of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

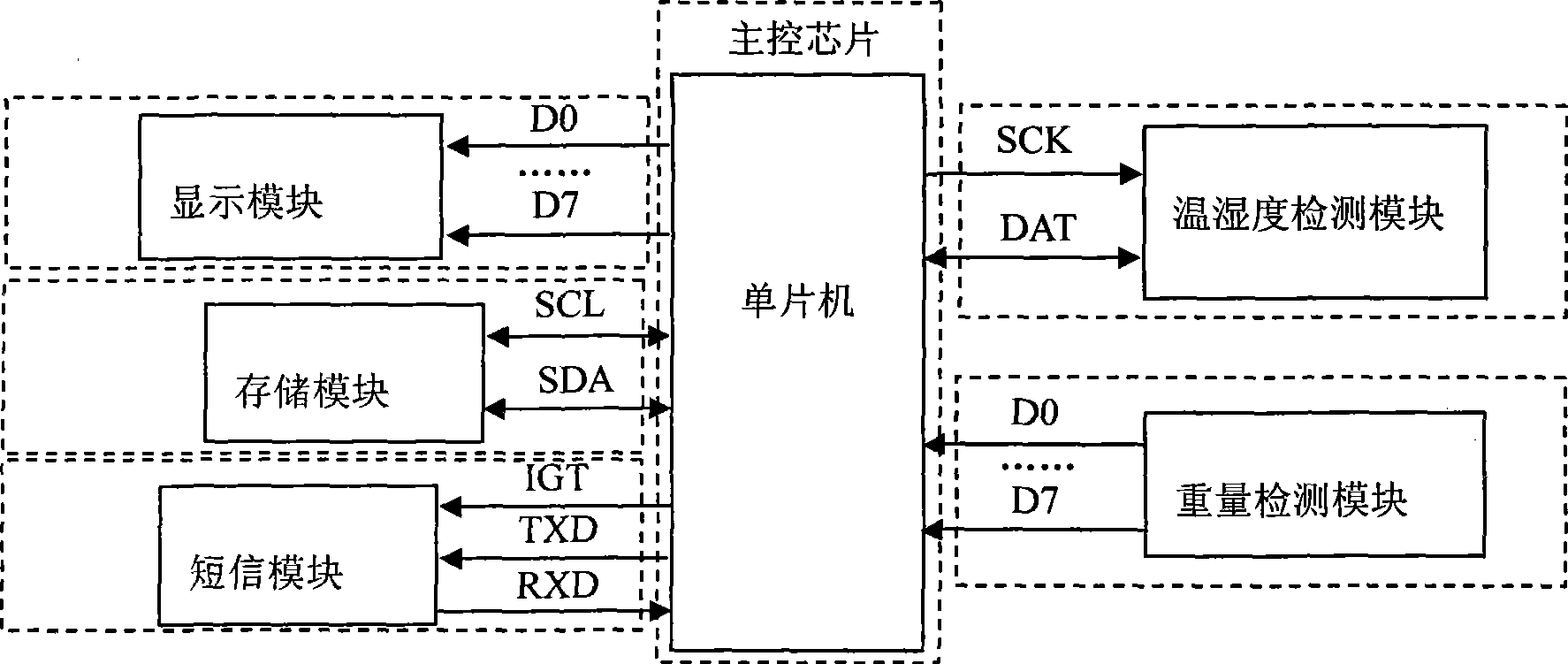

[0038] Example: Take STC89C52 microcontroller as the core, and connect SHT10 digital sensor to the I / O port as the temperature and humidity signal acquisition part; I 2 The C port is connected to the FM3130 chip, which is used as a real-time clock (RTC) and FRAM non-volatile memory; the serial port is connected to the TC35 module, which will send a text message to alarm when the system is abnormal; the liquid crystal module adopts the HB19264M1 liquid crystal module of Shenzhen Haibin Company.

[0039]Among them, the 64K ferroelectric non-volatile RAM function of the FM3130 chip is used as a data storage part. It has the function of automatically saving data when power off, which can be written indefinitely; it also has a real-time clock / calendar function, which can provide a system for the single-chip microcomputer. Time, which plays a role in simplifying the hardware structure and reducing costs.

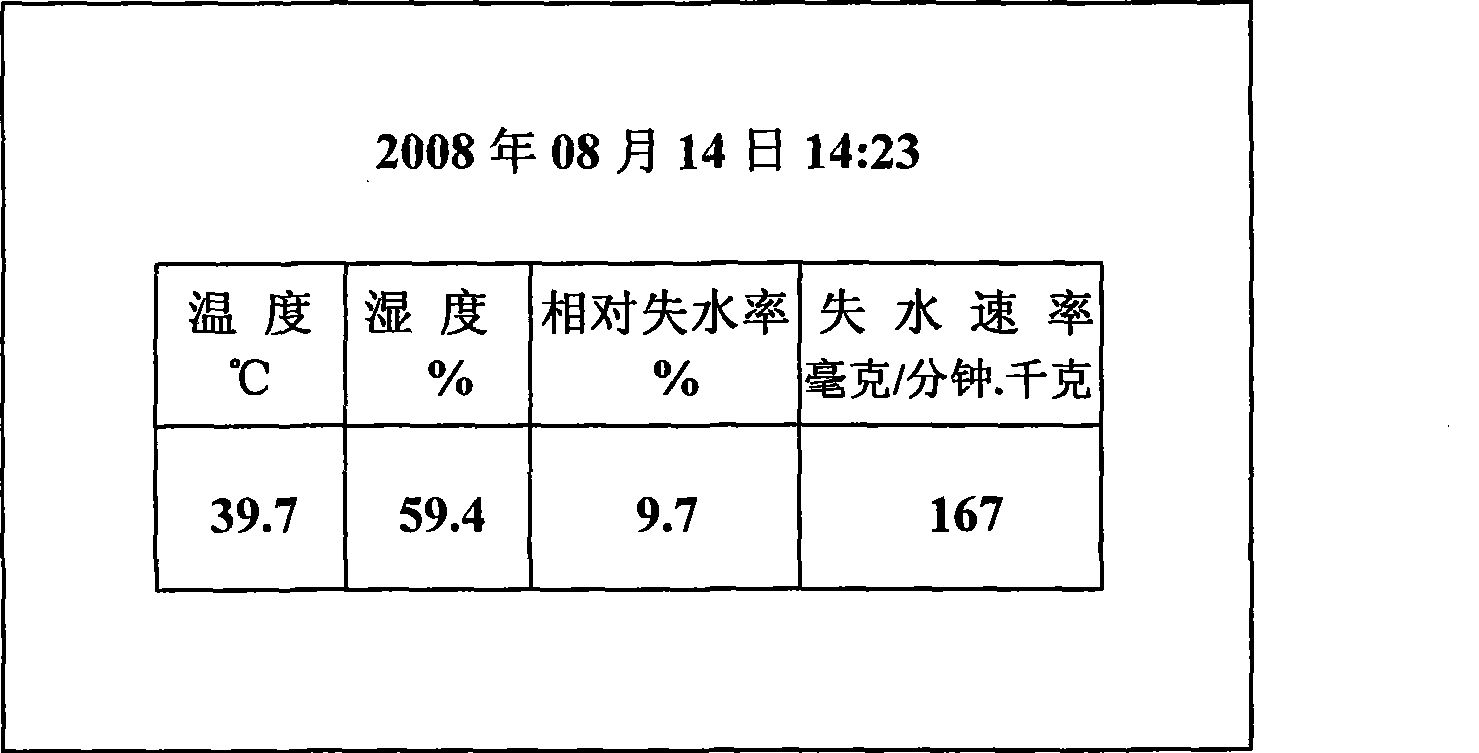

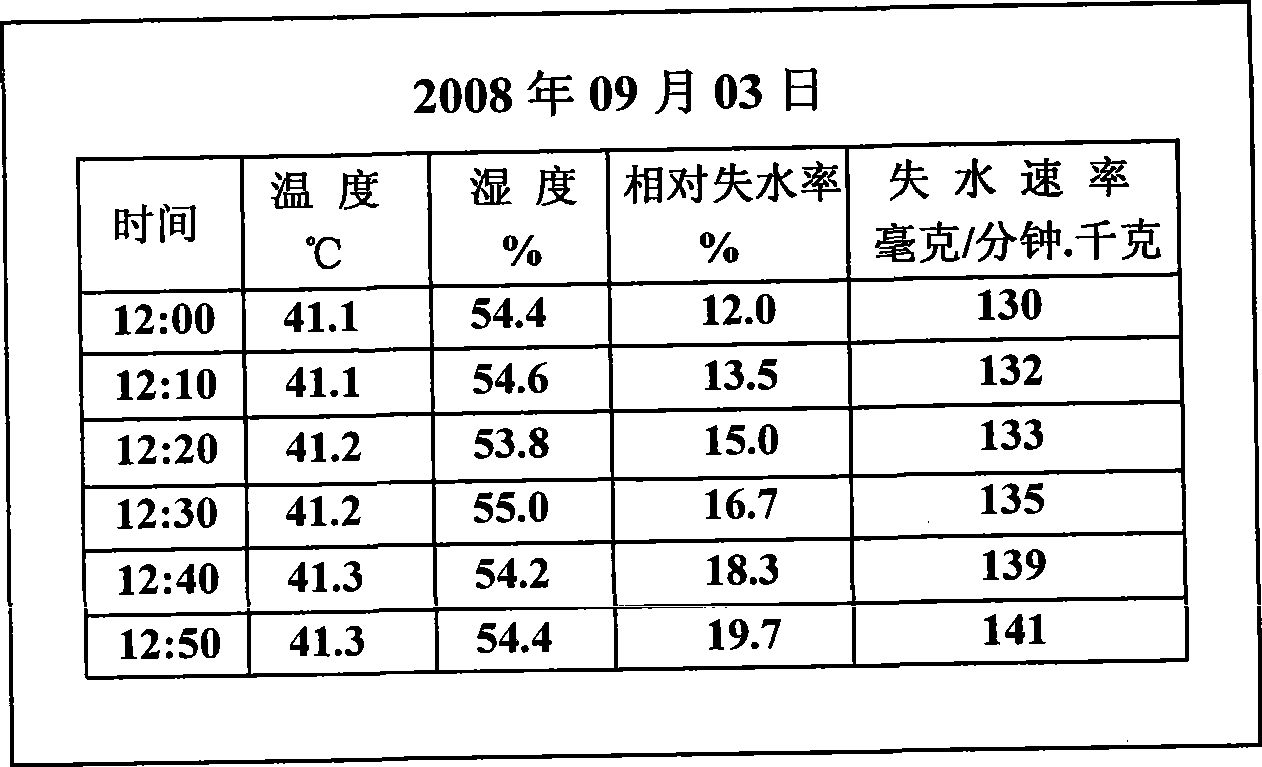

[0040] The system normally displays the real-time data in the barn, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com