Method for preparing artificial quartz

A technology of artificial quartz stone and natural quartz, which is applied to clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of complex preparation process, high production cost and high construction cost, and achieves simplified preparation process, low manufacturing cost, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

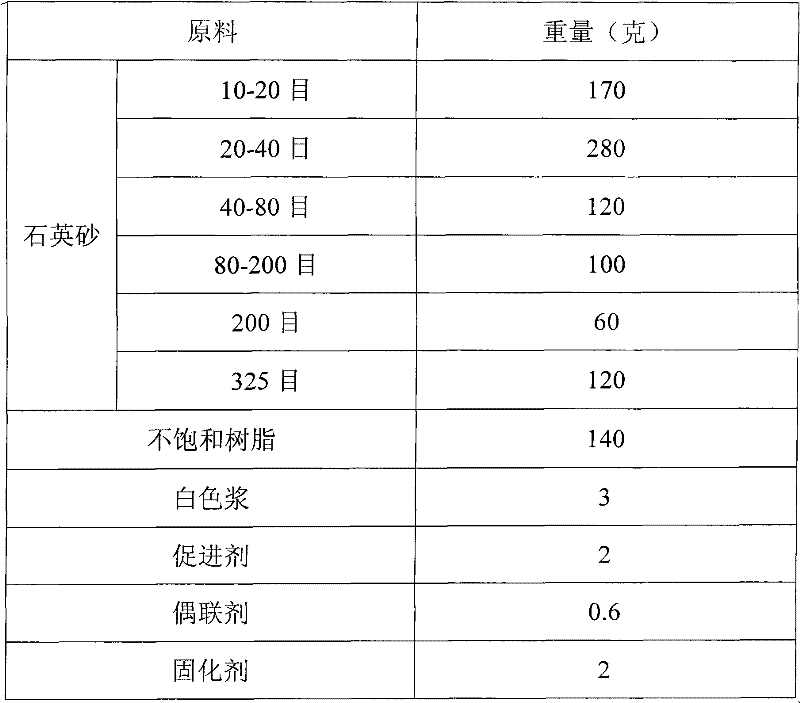

[0020] Embodiment 1: the production technology of white artificial quartz slate. Take the total weight of raw materials as 1kg as an example. Raw material ratio as shown in Table 1

[0021] Raw material ratio table in the embodiment 1 of table 1

[0022]

[0023] Weigh 3 grams of white slurry, add it to 140 grams of resin, stir evenly, then add 120 grams of 325-mesh quartz sand, stir fully, and then add quartz of other meshes in order of mesh number from large to small, each time After adding quartz, it needs to be fully stirred, and finally add accelerator, coupling agent and curing agent, and stir quickly to obtain the raw material for board making. Pour it into the board-making mold, send the mold into the vacuum box to evacuate, and keep it for about 8 minutes under the condition of vacuum degree of -0.1MPa, then take out the mold, and take a small amount of 10-20 mesh quartz sand evenly on the surface of the mold , and then let it solidify by itself, until the surfa...

Embodiment 2

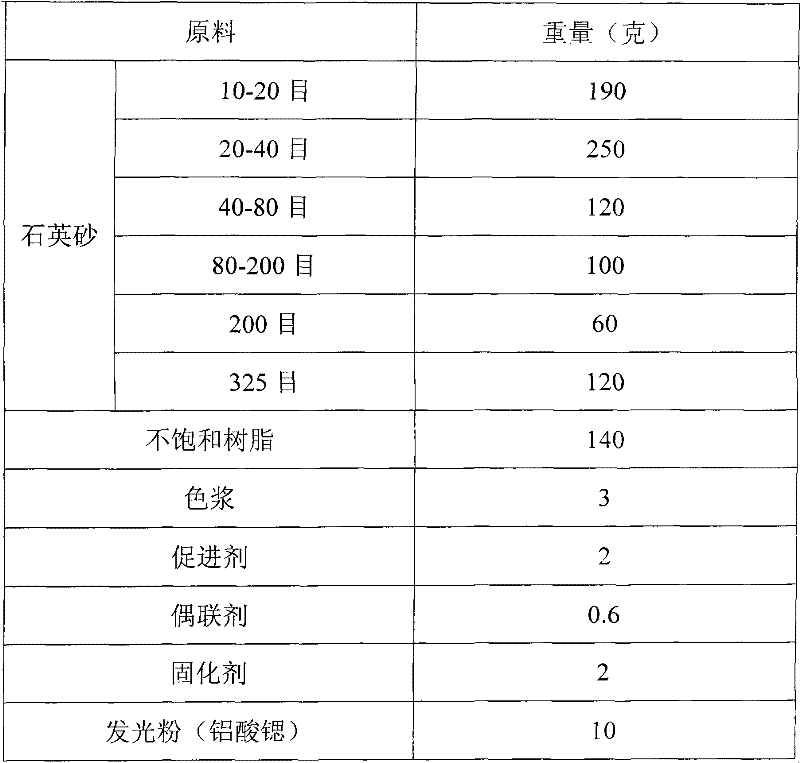

[0025] Example 2: The production process of luminous artificial quartz stone plate. Take the total weight of raw materials as 1kg as an example. Raw material ratio as shown in table 2

[0026] Raw material proportioning in table 2 embodiment 2

[0027]

[0028] Weigh 3 grams of color paste and 10 grams of luminescent powder respectively, add them into 140 grams of resin, and stir evenly. Other procedures are the same as in Example 1.

Embodiment 3

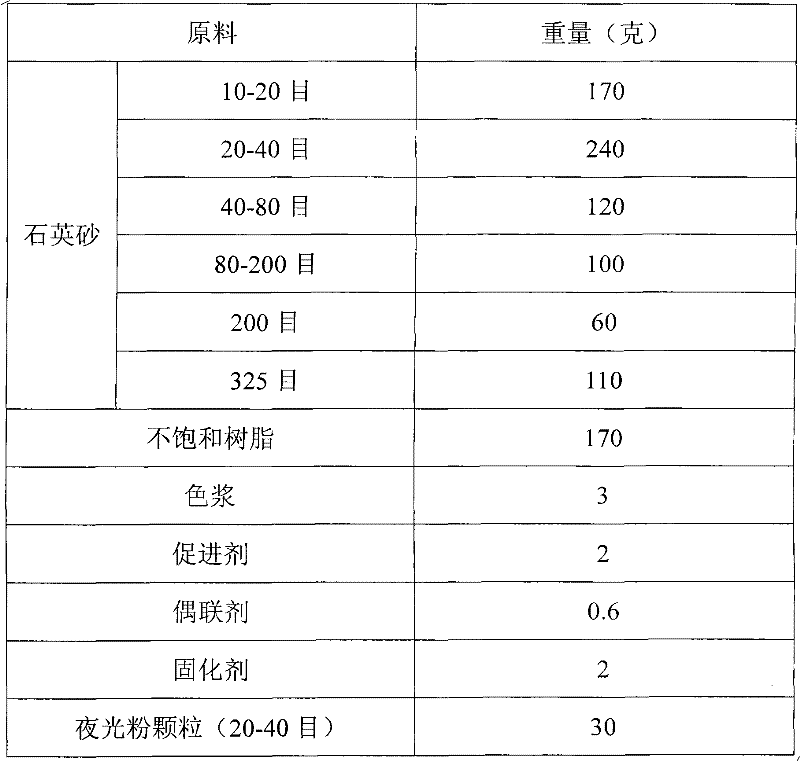

[0029] Example 3: The production process of artificial quartz stone plate containing luminous particles, taking the total weight of raw materials as 1kg as an example. Raw material ratio as shown in table 3

[0030] Ratio of raw materials in table 3 embodiment 3

[0031]

[0032] The first is the process of making luminous particles: 40g of unsaturated resin, 25g of light-storing luminescent powder, 30g of aluminum hydroxide powder, 0.4g of accelerator, 0.4g of curing agent, fully stirred, mixed evenly, poured into the mold, and Put the mold into the vacuum box for vacuuming, keep it out of the box for 3-5 minutes under the condition of vacuum degree of -0.1MPa, leave it at room temperature for a period of time, make it completely solidified, and then crush and sieve to obtain 20-40 Purpose luminous powder particles. Take 30 grams of 20-40 mesh luminous powder particles and 240 grams of 20-40 mesh quartz stones and mix them evenly for later use; other procedures are the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com