Method for preparing hollow fabric sheet material

A fabric and hollow technology, which is applied in the field of preparation of hollow fabric sheets, can solve the problems that affect the comprehensive performance of hollow fabric sheets, the consistency of thickness is difficult to guarantee, and the resin content is difficult to control, and the resin content, thickness and resin distribution are easy to achieve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

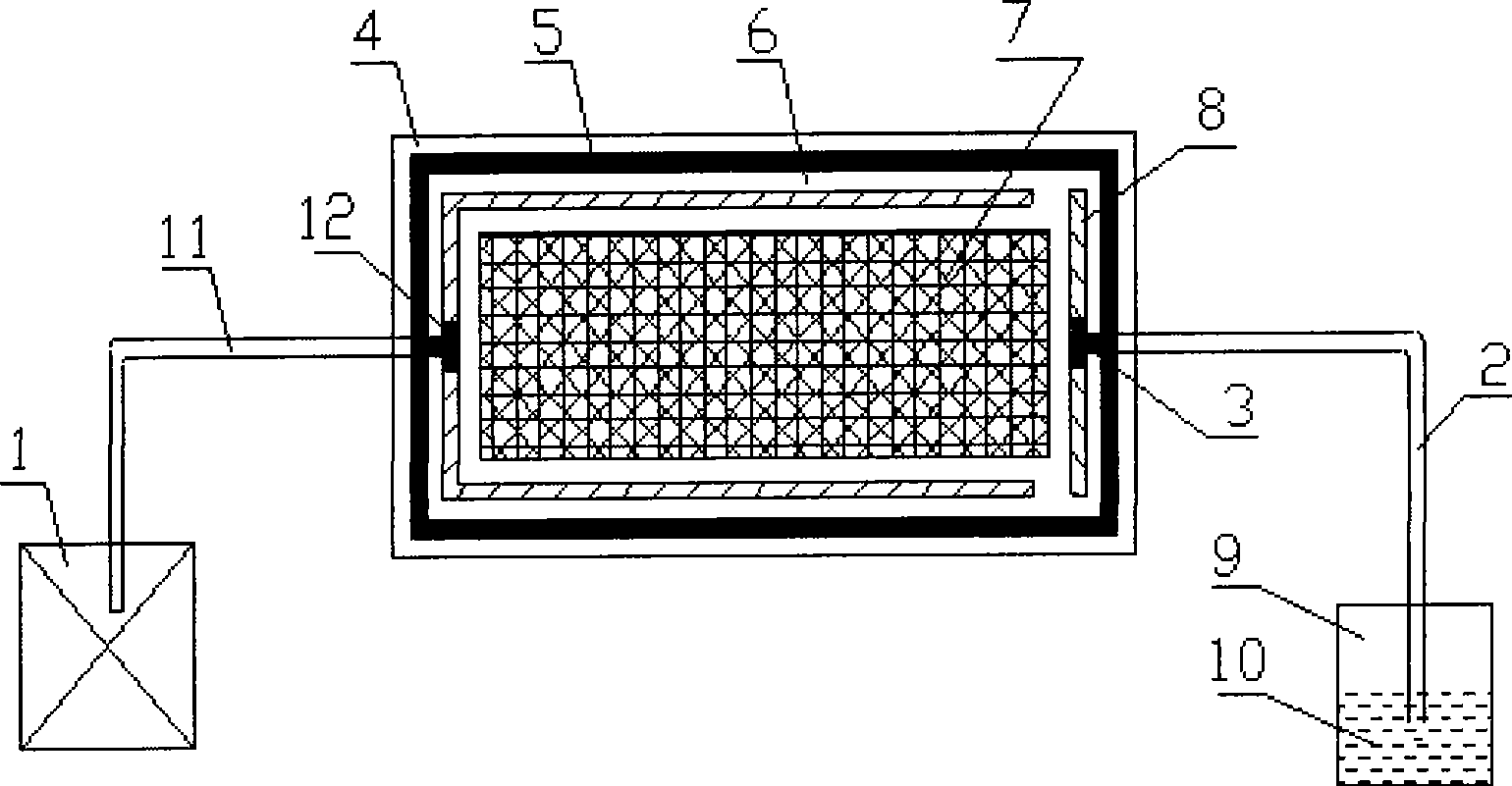

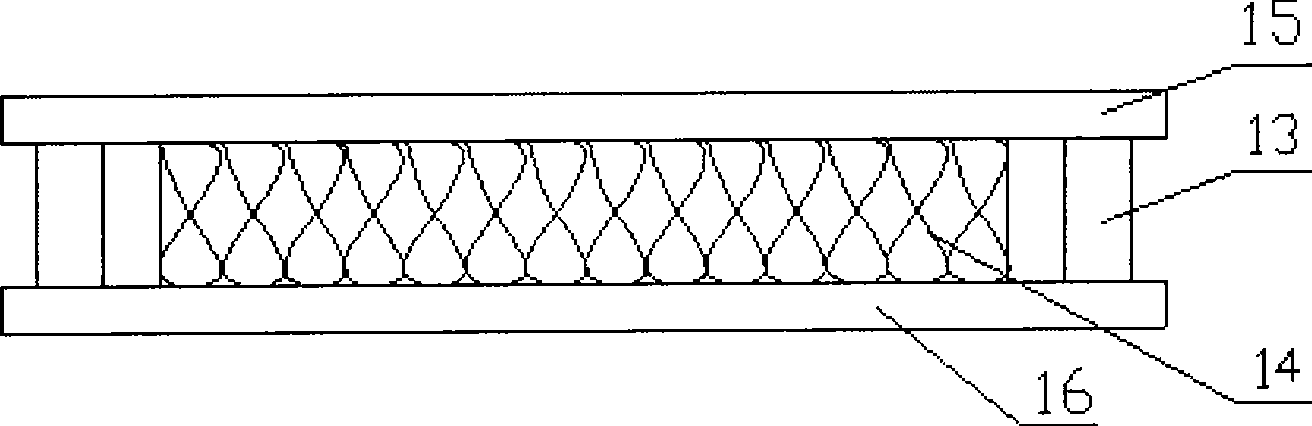

[0017] 1. If figure 1 As shown, brush a layer of release agent on the prepared fixed plate 4, spray a small amount of fixative, and then spread the upper and lower layers of guide cloth. The hollow fabric 14 is placed on the lower floor guide cloth, spray a small amount of fixing agent on the fabric and then cover the upper layer guide cloth, wherein the surface of the guide cloth will be controlled to keep flat. Spray a small amount of fixing agent on the upper strata diversion cloth again, then spread diversion net 7 on the upper strata diversion cloth. Install feed guide pipe 8 on one side of fixed plate 4, install discharge guide pipe 6 on the remaining three sides, and feed guide pipe 8 communicates with feed latex pipe 2 through feed tee copper pipe 3, The feed latex pipe 2 communicates with the resin tank 9, the discharge diversion pipe 6 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com