Process and apparatus for treating oil-gas field wastewater

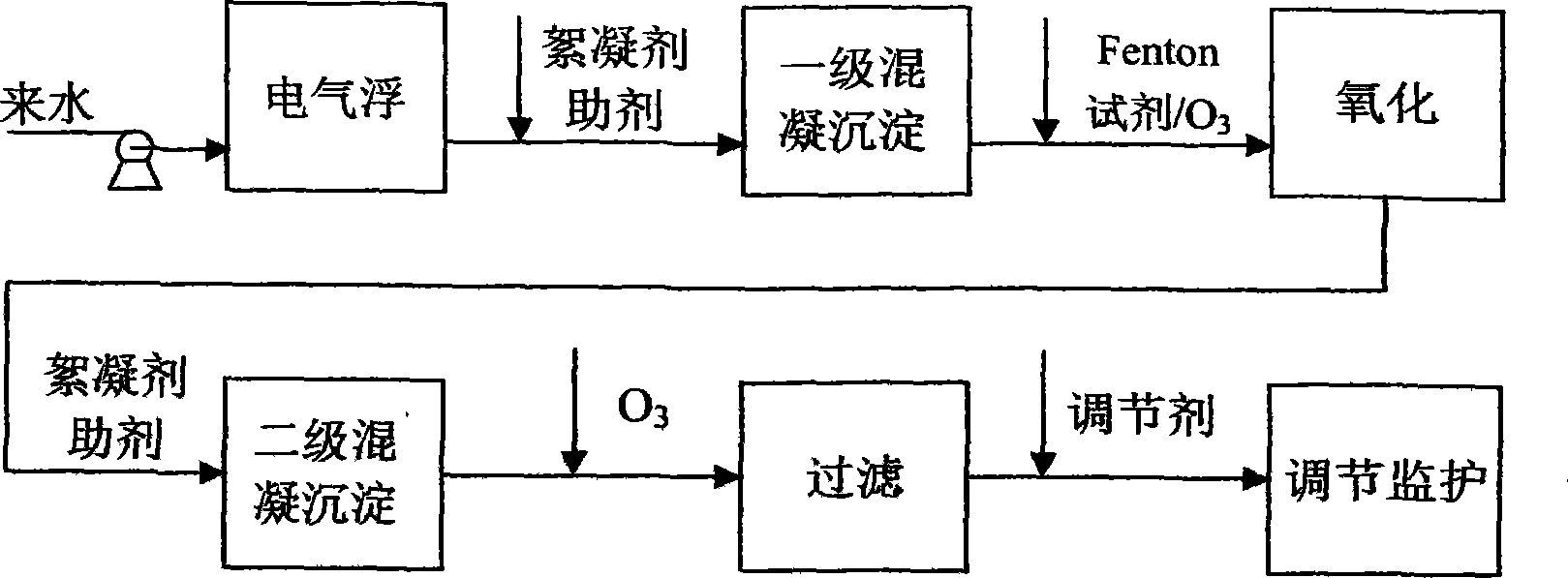

A technology for wastewater treatment and oil and gas fields, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc. Low power consumption, strong processing power, and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

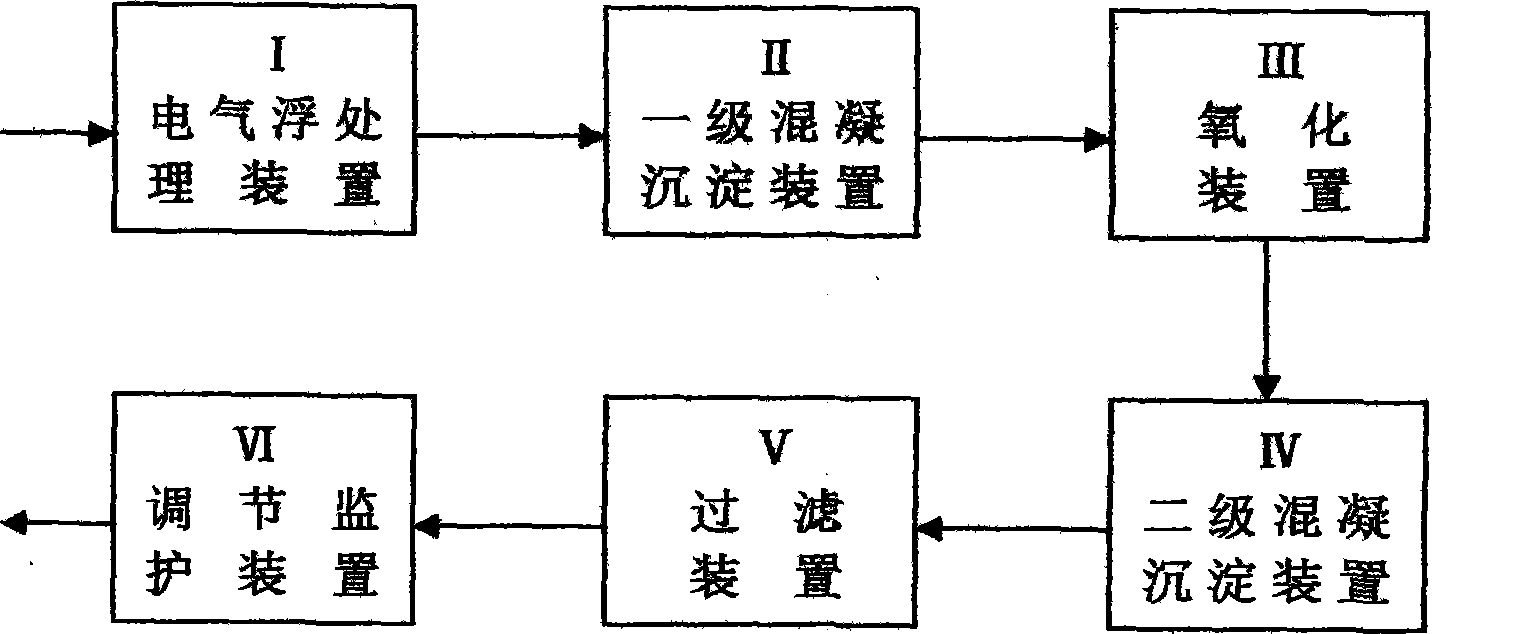

[0041] see figure 2 : This oil and gas field wastewater treatment device includes electric floating treatment device I, primary coagulation and sedimentation device II, oxidation device III, secondary coagulation and sedimentation device IV, filter device V, and adjustment and monitoring device VI arranged in sequence. The structure of each part is described as follows.

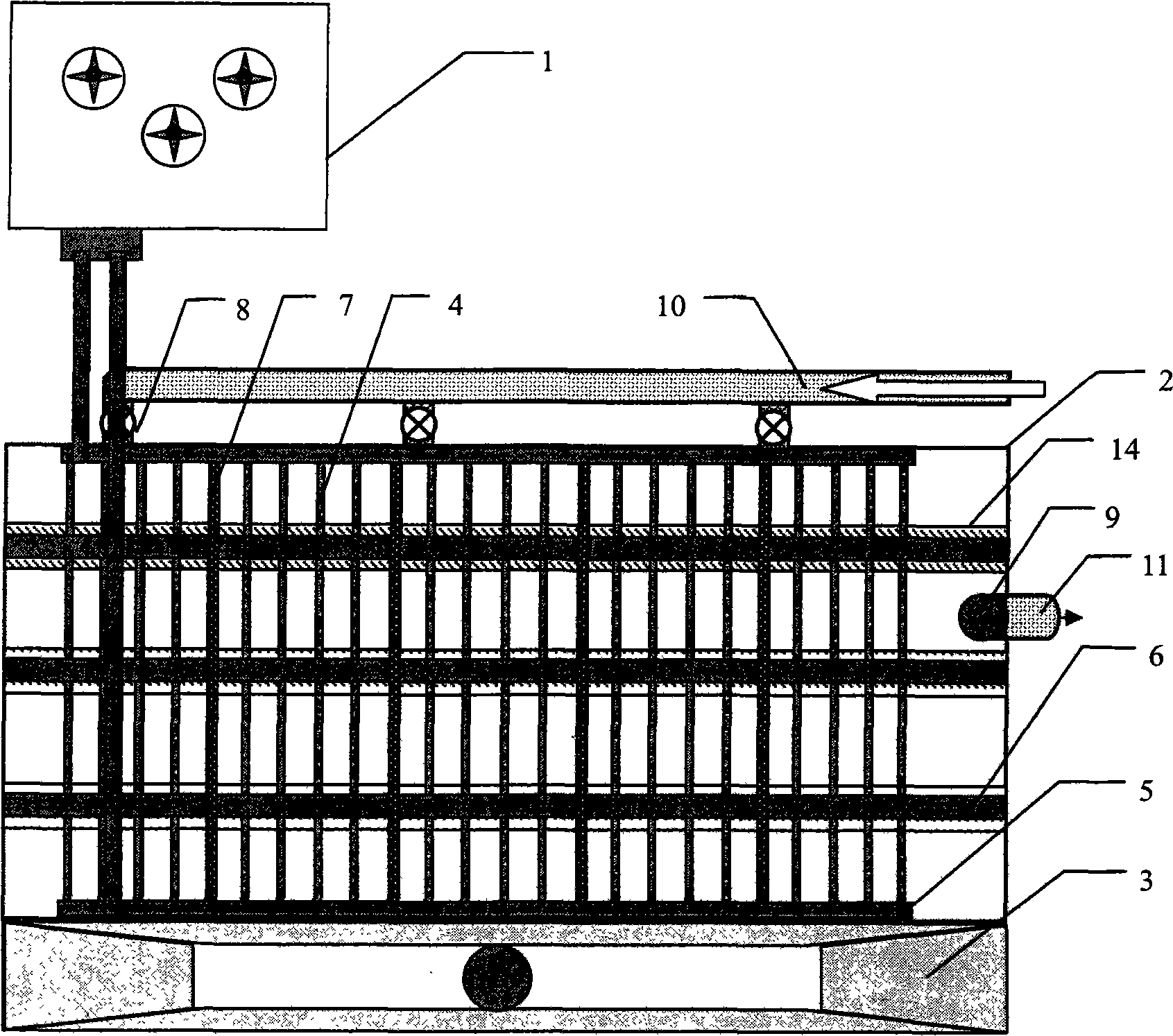

[0042] see Figure 3-1 , Figure 3-2 : the electric floating treatment device 1 comprises a power supply 1, an electrolyzer 2, and a slag overflow tank 3. In the electrolytic cell 2, a plurality of pole plates 4 are vertically dispersed and arranged. The pole plates 4 are divided into two groups, one group is the anode, and the other is the cathode. Connection, bus 5 is connected to power supply 1.

[0043] The pole plate 4 is made of ordinary carbon steel, installed in parallel on the pole plate fixing card 6 in the electrolytic cell 2, and supported by the Cao steel bracket 14; the bus bar 5 uses coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com