A kind of pleuromutilin extraction process

A technology of pleuromutilin and extraction process, which is applied in the field of extraction process of raw material pleuromutilin mycelium, to achieve the effect of benefiting the health, shortening the production cycle, and improving the economic and social benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

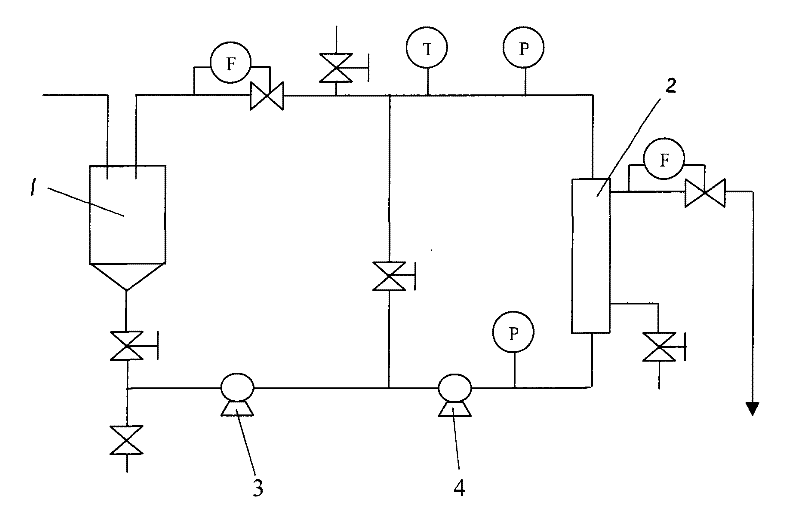

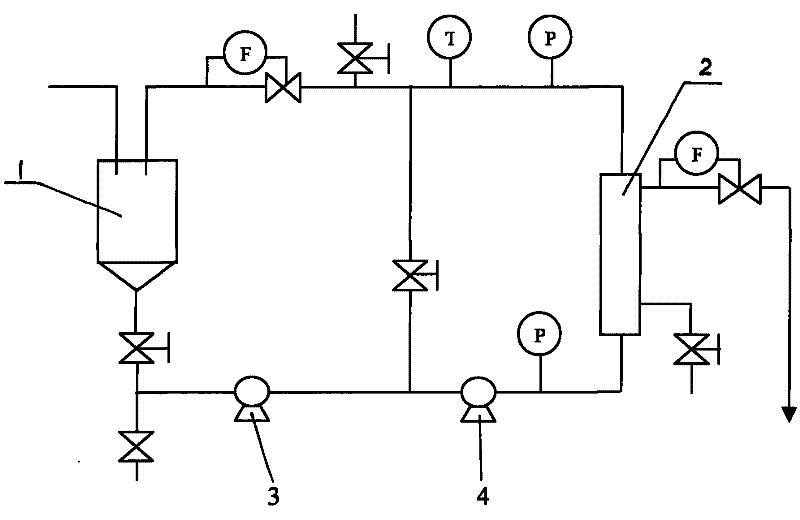

[0020] Embodiment 1: as figure 1 As shown, after putting the pleuromutilin mycelia with a water content of 20 to 30% into the extraction tank 1, methanol solvent is added in a ratio of 1:3 to 1:6 in parts by weight, and at room temperature 20 to 40°C After continuous stirring for 3-6 hours under high temperature, the extract solution was made, and then the extract solution was filtered through a ceramic membrane 2 with a pore size of 1 μm-20 nm under a pressure of 0.2-0.6 Mpa through a feed pump 3, wherein the ceramic membrane 2 was made of Jiangsu The ceramic filter membrane with a pore size of 1 μm to 20 nm produced by Jiuwu High-Tech Co., Ltd. or Germany ATECH Technology Development Co., Ltd. sends the filtrate that passes through the ceramic membrane 2 to the subsequent semi-finished product processing system. Lift tank 1, another part of raffinate passes through circulation pump 4 and then circulates and filters through ceramic membrane 2, and controls the ratio of the fl...

Embodiment 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that methanol solvent is replaced by ethanol solvent.

Embodiment 3

[0022] Example 3: The difference between this example and Example 1 is that the methanol solvent is replaced by ethanol solvent, and the ceramic membrane is replaced by a stainless steel membrane with a pore size of 1 μm to 50 nm produced by Hebei Ruitong Meibang Engineering Co., Ltd. or Kaimembrane Filtration Technology Co., Ltd. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com