Melamine-formaldehyde impregnating resin and preparing method thereof

A technology of melamine and impregnated resin, which is applied in the field of resin and its manufacture, can solve the problems of high production cost and high price of melamine-formaldehyde impregnated resin, and achieve the effects of saving resources and energy consumption, improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 3500kg of purified water, 7500kg of formaldehyde, 600kg of diethylene glycol and 720kg of modifier into the reaction kettle in sequence, stir and add 7L of sodium hydroxide solution to adjust the pH value to 9.23, then add 6800kg of melamine and stir for 10 minutes , the temperature was raised to 90.1°C within 30 minutes, and the control system reacted for 30 minutes at a temperature of 90.1°C and a pH value of 9.23. When it drops below 30°C, adjust the pH value to 8.92, then take samples and discharge.

[0020] Various test results

[0021] Test items Quality Index Test results Exterior colorless transparent liquid colorless transparent liquid pH value 8.5-9.6 9.0

[0022] Viscosity (s / 20℃) coated with 4# cup 15-25 18 Solid content (wt%) 45-60 56 Water soluble ratio (25℃) 1.5-2.5 1.9 Free formaldehyde (wt%) ≤0.3 0.3

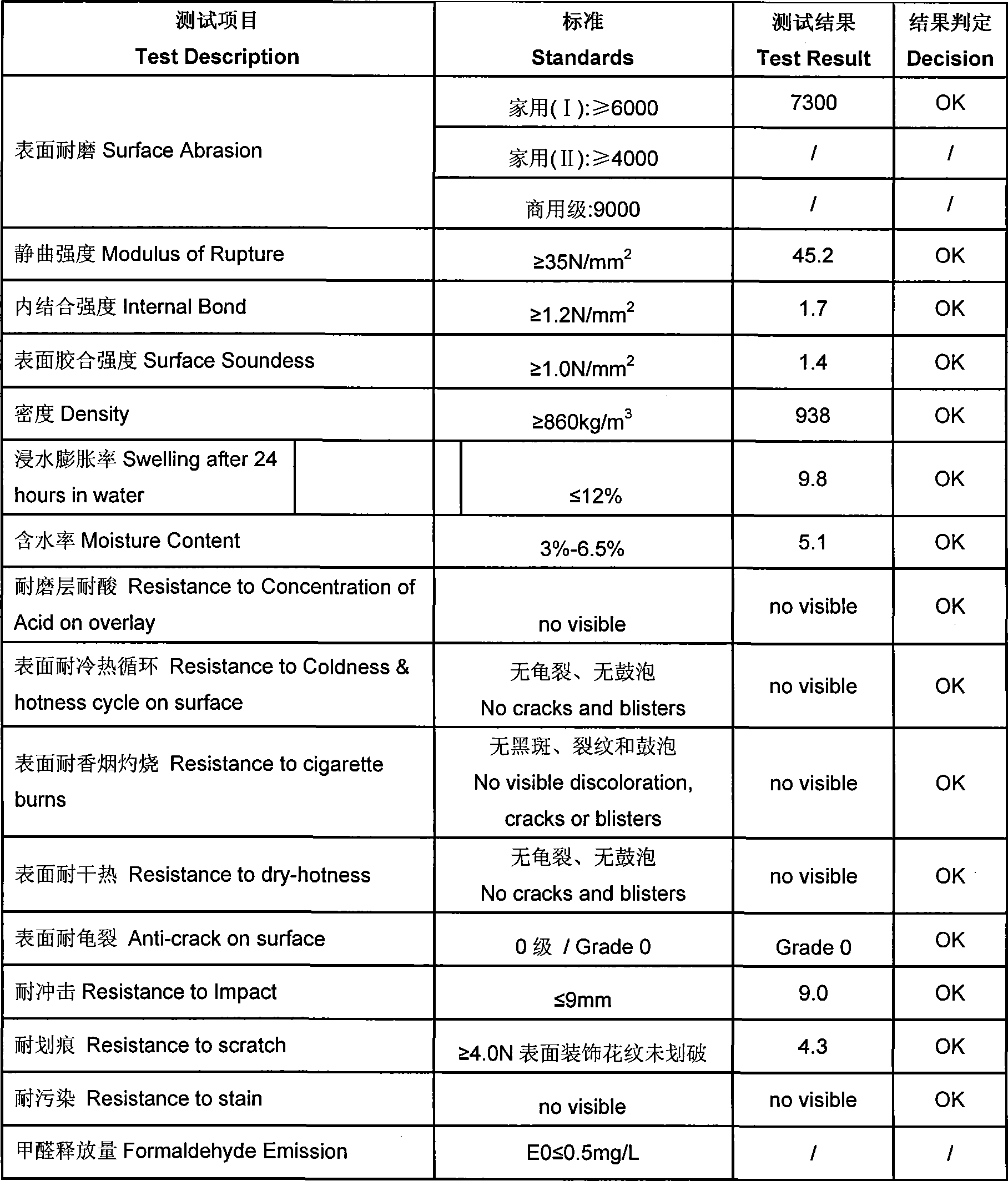

[0023] Floor inspection indicators:

[0024]

[0025]

Embodiment 2

[0027] Add 3274kg of purified water, 6100kg of formaldehyde, 400kg of diethylene glycol and 600kg of modifier into the reactor in sequence, stir and add 8L of sodium hydroxide solution to adjust the pH value to 9.5, then add 5426kg of melamine and stir for 10 minutes , the temperature was raised to 85°C within 40 minutes, and the control system reacted for 30 minutes at a temperature of 85°C and a pH value of 9.5, and then a sample was taken to detect the water solubility of the reaction solution. When it drops below 30°C, adjust the pH value to 9.6, then take samples and discharge.

[0028] Various test results

[0029] Test items Quality Index Test results Exterior colorless transparent liquid colorless transparent liquid pH value 8.5-9.6 9.5 Viscosity (s / 20℃) coated with 4# cup 15-25 17 Solid content (wt%) 45-60 53.9 Water soluble ratio (25℃) 1.5-2.5 1.6 Free formaldehyde (wt%) ≤0.3 0.2

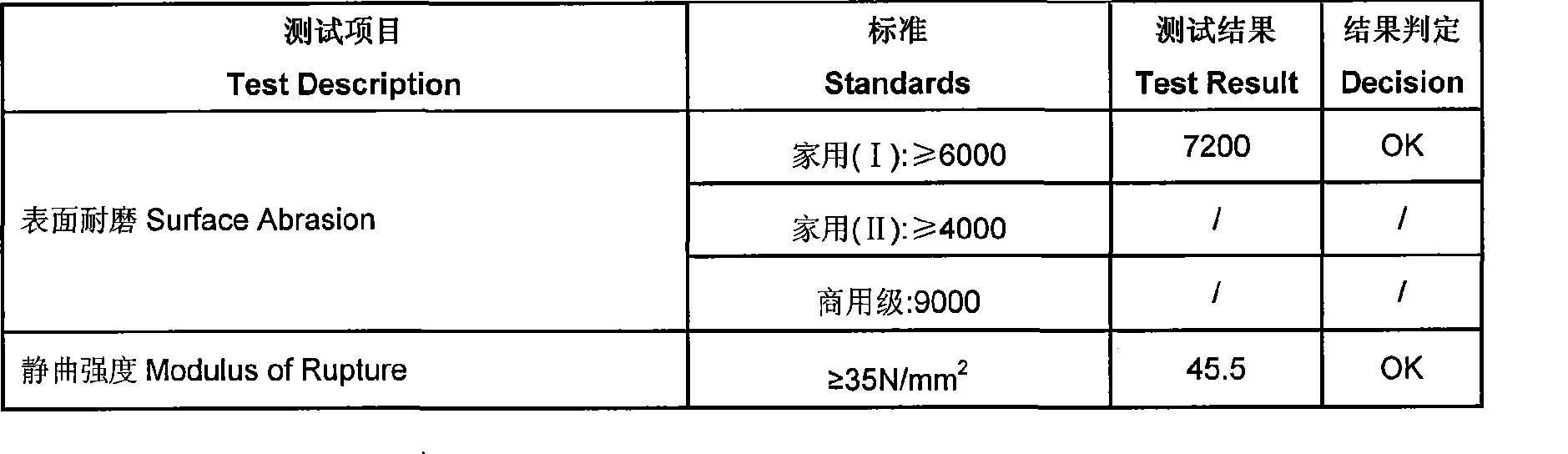

[0030] Floor inspection ...

Embodiment 3

[0034] Add 1990kg of purified water, 7290kg of formaldehyde, 324kg of diethylene glycol and 162kg of modifiers into the reaction kettle in sequence, stir and add 7L of sodium hydroxide solution to adjust the pH value to 9.26, then add 6434kg of melamine and stir for 10 minutes , the temperature was raised to 90.1°C within 30 minutes, and the control system was reacted at a temperature of 90.1°C and a pH value of 9.26 for 30 minutes, and then samples were taken to detect the water solubility of the reaction solution. When it drops below 30°C, adjust the pH value to 8.97, then take samples and discharge.

[0035] Various test results

[0036] Test items Quality Index Test results Exterior colorless transparent liquid colorless transparent liquid pH value 8.5-9.6 9.0 Viscosity (s / 20℃) coated with 4# cup 15-25 18 Solid content (wt%) 45-60 59 Water soluble ratio (25℃) 1.5-2.5 1.9 Free formaldehyde (wt%) ≤0.3 0.3

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com