System and method for polishing surface of tape-like metal base material

一种金属基材、带状的技术,应用在研磨装置、研磨机床、金属加工设备等方向,能够解决氧化物超传导体临界电流密度低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

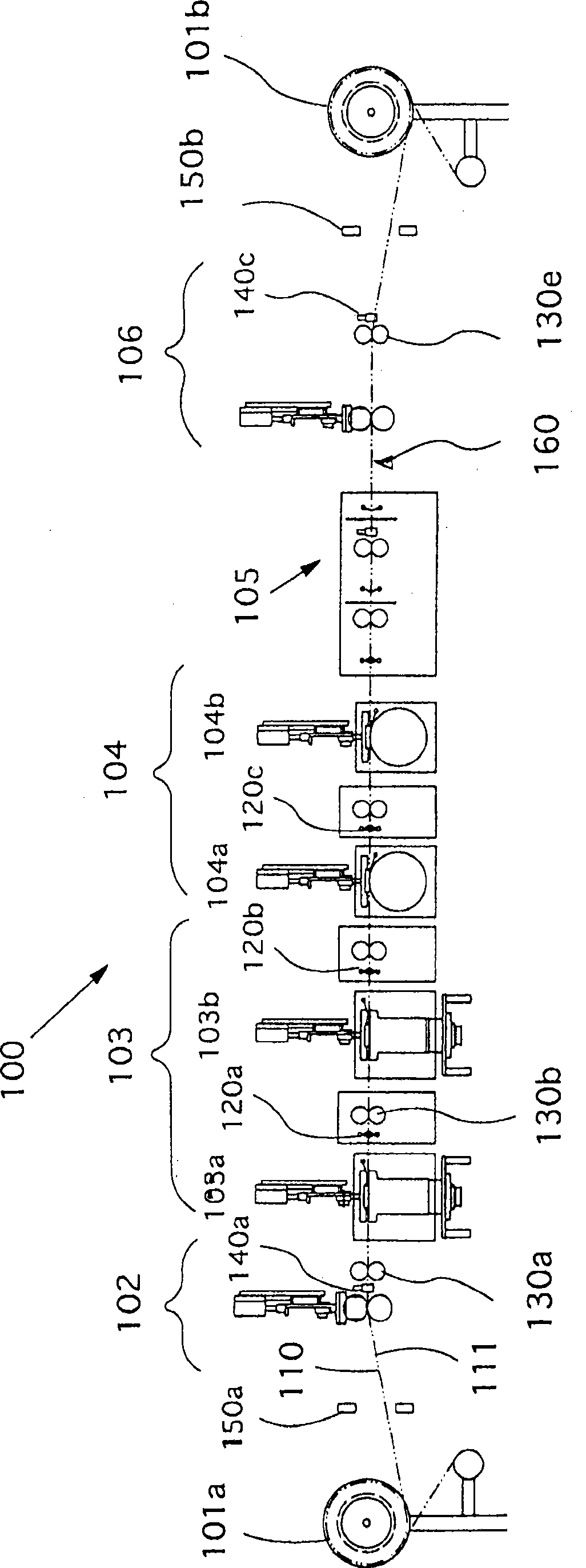

[0110] Instructions for use figure 1 With the grinding system of the present invention shown, experiments were performed to grind a strip-shaped metal substrate.

[0111] 1. Experimental conditions

[0112] (1) Strip metal substrate: nickel alloy (Ni: 58.0wt%, Cr: 15.5wt%, Fe: 5.0wt%, W: 4.0wt%, also contains Co, etc.) width 10mm, length 100m, thickness 0.1mm

[0113] (2) The first polishing step: a tape body with a width of 150 mm and a thickness of 500 μm formed by foaming polyurethane on a PET film was used as the polishing tape

[0114] Rotational speed of the grinding head (rpm): 30~80 for the first stage, 30~80 for the second stage

[0115] Direction of rotation: 1st stage clockwise, 2nd stage counterclockwise

[0116] Pressure (g / cm 2 ): Level 1 100~500, Level 2 100~500

[0117] Slurry flow rate (ml / min): 5~30 for the first stage, 5~30 for the second stage

[0118] (3) The second grinding process: use non-woven fabric made of polyester fiber as the liner used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com