Method for producing crystal structure electrodes for oriented pzt capacitors

一种电容器、晶体结构的技术,应用在电容器、电固体器件、半导体/固态器件制造等方向,能够解决不能够防止氧扩散、无法进行等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

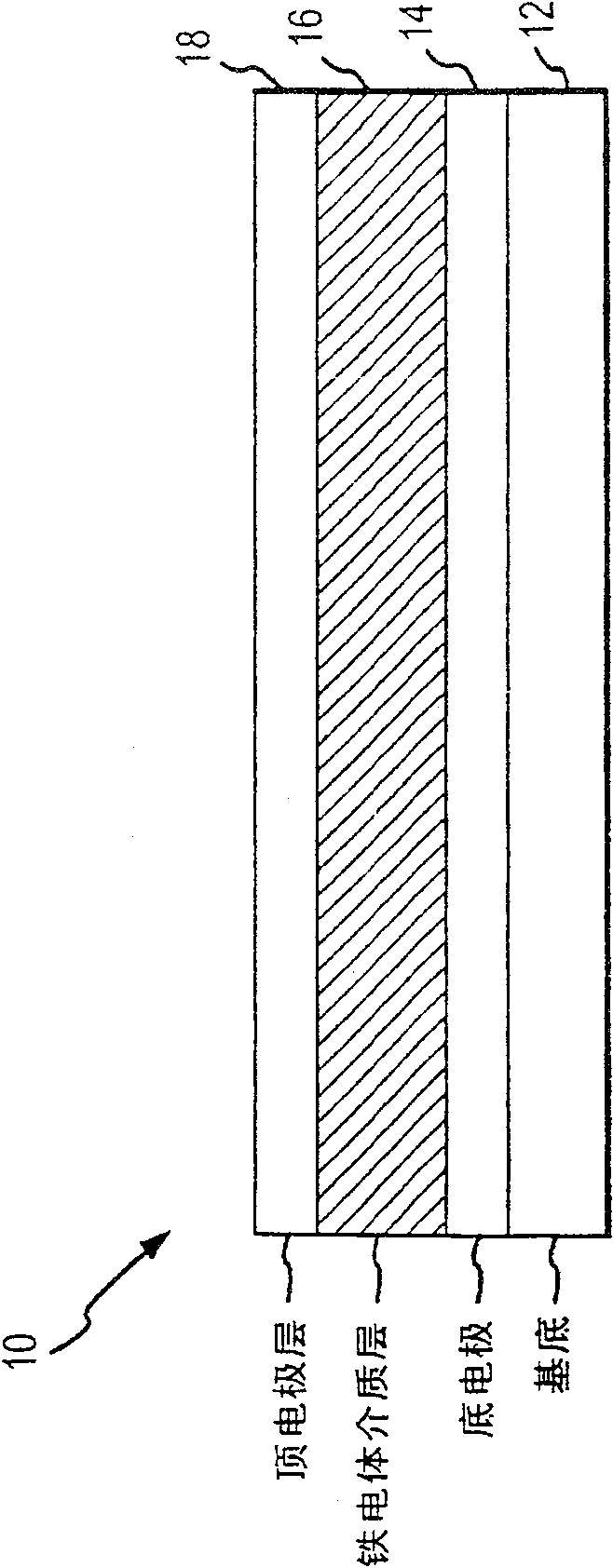

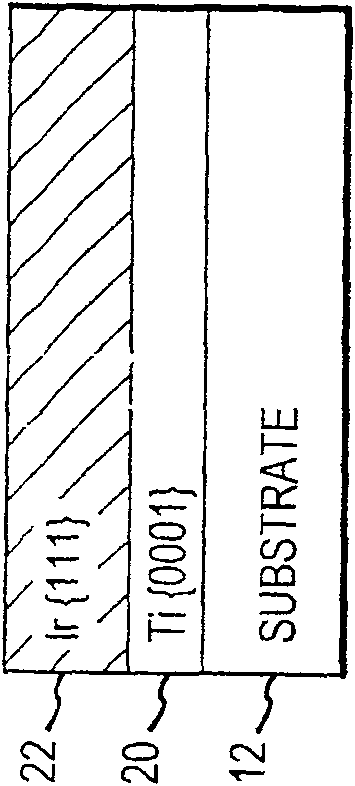

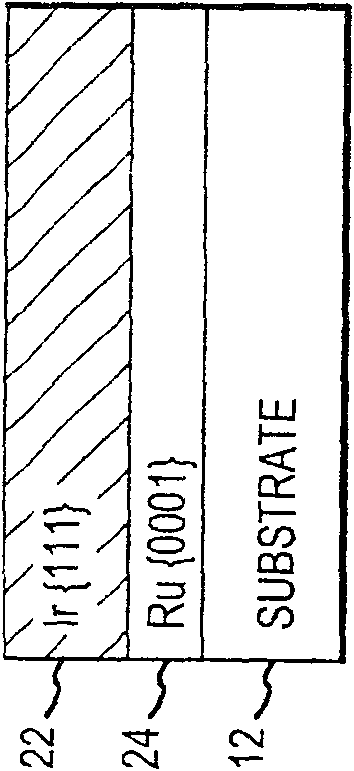

[0034] see now Figure 2-10 and 18, the bottom electrode structure for a ferroelectric capacitor includes a close-packed hexagonal crystal seed layer and an iridium bottom electrode layer 22. A seed layer is deposited on substrate 12, forming a layer about 200 angstroms thick. An iridium bottom electrode layer 22 is deposited on the surface of the seed layer to form a layer about 500-1000 angstroms thick. The seed layer can be composed of a variety of different substances, as will be further described below. The ideal seed layer has a rocking curve with a width at half maximum ("FWHM") of less than five degrees (002 for a hexagonal crystal or 200 for a tetragonal seed layer). A "rocking curve" refers to a measurement of the diffraction intensity as a function of sample rotation and maintains the Bragg conditions of diffractive crystal planes when using X-ray and electron diffraction techniques in order to determine the orientation of the deposited film. Width at half maximum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deposition rate | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com