Method of and apparatus for producing formable products

A product and material forming technology, applied in the field of producing formable products and machinable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0214] Other implementations include:

[0215] 1) One or more mobile transmitters / one or more antennas - physically moving relative to the workload which, when coupled to the moving cavity, can create a moving standing wave across the material to be heated;

[0216] 2) One or more directional emitters / antennas designed to produce a predictable and desired heating pattern in the far field, and more preferably in the near field, to direct energy towards the workload and achieve targeted heating;

[0217] 3) A system comprising a microwave transparent mold located in a microwave reflective cavity;

[0218] 4) A system based on one or more of the above, but using absorbing walls and / or sloped or serrated walls to dampen or destroy harmonics of the resonant cavity and to simplify or control the field distribution within the cavity;

[0219] 5) A system incorporating one or more of the above features.

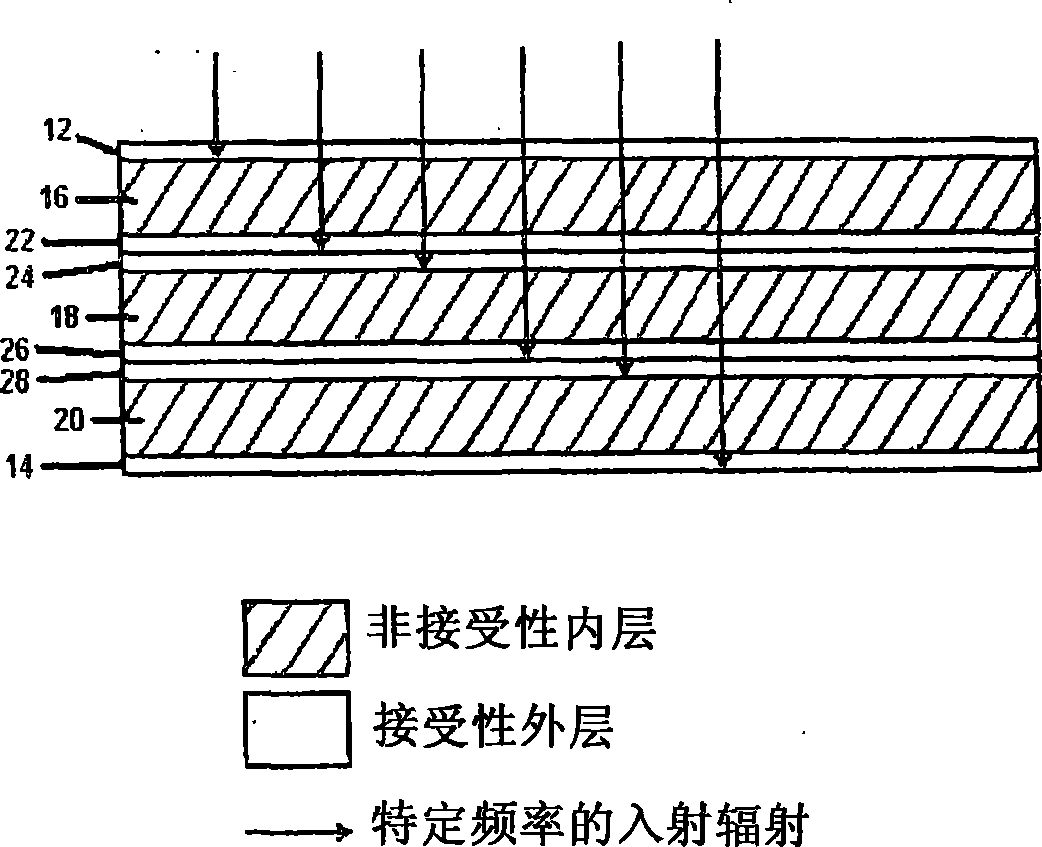

[0220] targeted heating

[0221] Solid-state transmitters are now sufficientl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com