Modified diene rubber and rubber composition containing the same

A diene-based rubber and modification technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve the problems of reduced reaction efficiency, reduced import rate, high load, and improved dispersion. , Excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

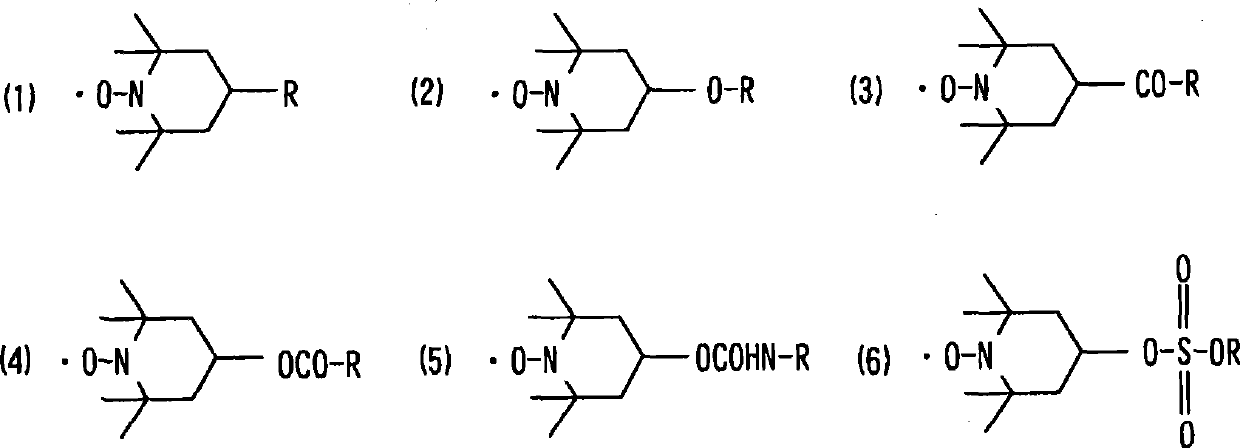

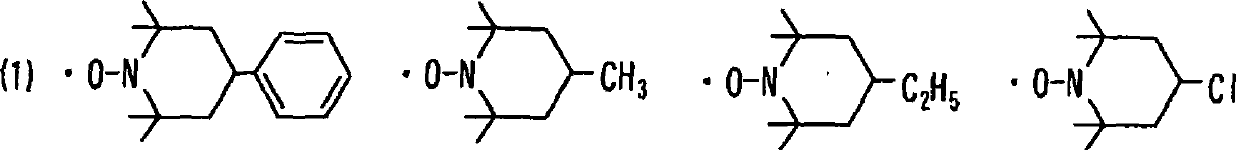

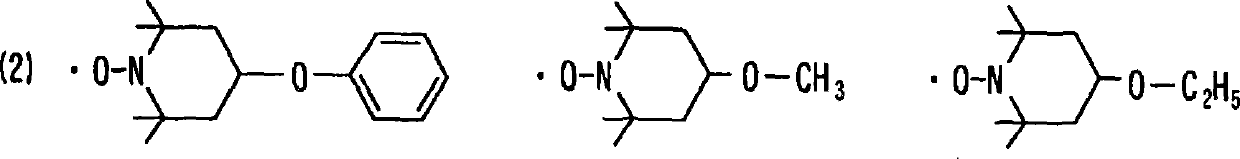

Method used

Image

Examples

manufacture example 1

[0097] Manufacturing Example 1: Manufacturing of DHK-2F

[0098] 350 g (5.14 moles) of synthetic polyisoprene rubber (NipolIR2200 manufactured by Nippon Zeon Co., Ltd.), 8.86 g (0.0514 moles) of hydroxyl TEMPO (OH-TEMPO) (manufactured by NOF Corporation) and 0.378 g (produced by decomposition) The molecular conversion of free radicals is 5.16×10 -3 mole, the mole number and mole % of the following free radical initiators are all expressed in this way) di-tert-butyl peroxide (manufactured by NOF Co., Ltd.) パブブル D, in a 600cc airtight container with a temperature set at 60°C Mix and disperse in a type mixer for 5 minutes (pre-mix). This premixed rubber was kneaded for 10 minutes under a nitrogen atmosphere in an internal kneader set at a temperature of 100° C. and discharged. The temperature at the end of mixing was 185°C. A part of the sample was taken from the rubber, and the sample was dissolved in toluene in order to remove hydroxyl TEMPO not bonded to rubber molecules a...

manufacture example 2

[0100] Manufacturing Example 2: Manufacturing of DHK-3F

[0101] Make 350g (5.14 moles) of the above-mentioned synthetic polyisoprene rubber, 8.86g (0.0514 moles) of the above-mentioned hydroxyl TEMPO and 0.184g (2.517×10 -3 mol) the above-mentioned di-tert-butyl peroxide was mixed and dispersed for 5 minutes in a 600 cc closed mixer set at a temperature of 60° C. (pre-mixing). This premixed rubber was kneaded for 10 minutes under a nitrogen atmosphere in an internal kneader set at a temperature of 100° C. and discharged. The temperature at the end of mixing was 185°C. A part of the sample was taken from the rubber, and the sample was dissolved in toluene in order to remove hydroxyl TEMPO not bonded to rubber molecules and peroxide residues, and then dropped into methanol to solidify and recover. This operation was performed 3 times, and then 1H-NMR measurement was performed to calculate the grafted hydroxyl group TEMPO amount. The introduction rate of hydroxyl TEMPO was ...

manufacture example 3

[0103] Manufacturing Example 3: Manufacturing of DHK-4F

[0104] Make 350g (5.14 moles) of the above-mentioned synthetic polyisoprene rubber, 8.86g (0.0514 moles) of the above-mentioned hydroxyl TEMPO and 0.213g (2.517×10 -3 mol) bis(2-tert-butylperoxyisopropyl) benzene (Parbull P manufactured by NOF Co., Ltd.), was mixed and dispersed for 5 minutes in a 600cc closed mixer with a temperature setting of 60°C ( premixed). This premixed rubber was kneaded for 10 minutes under a nitrogen atmosphere in an internal kneader set at a temperature of 100° C. and discharged. The temperature at the end of mixing was 185°C. A part of the sample was taken from the rubber, and the sample was dissolved in toluene in order to remove hydroxyl TEMPO not bonded to rubber molecules and peroxide residues, and then dropped into methanol to solidify and recover. This operation was performed 3 times, and then 1H-NMR measurement was performed to calculate the grafted hydroxyl group TEMPO amount. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com