Methods and apparatus for beam density measurement in two dimensions

A beam density and measurement technology, applied in the field of two-dimensional beam density measurement, can solve the problem of not being large enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

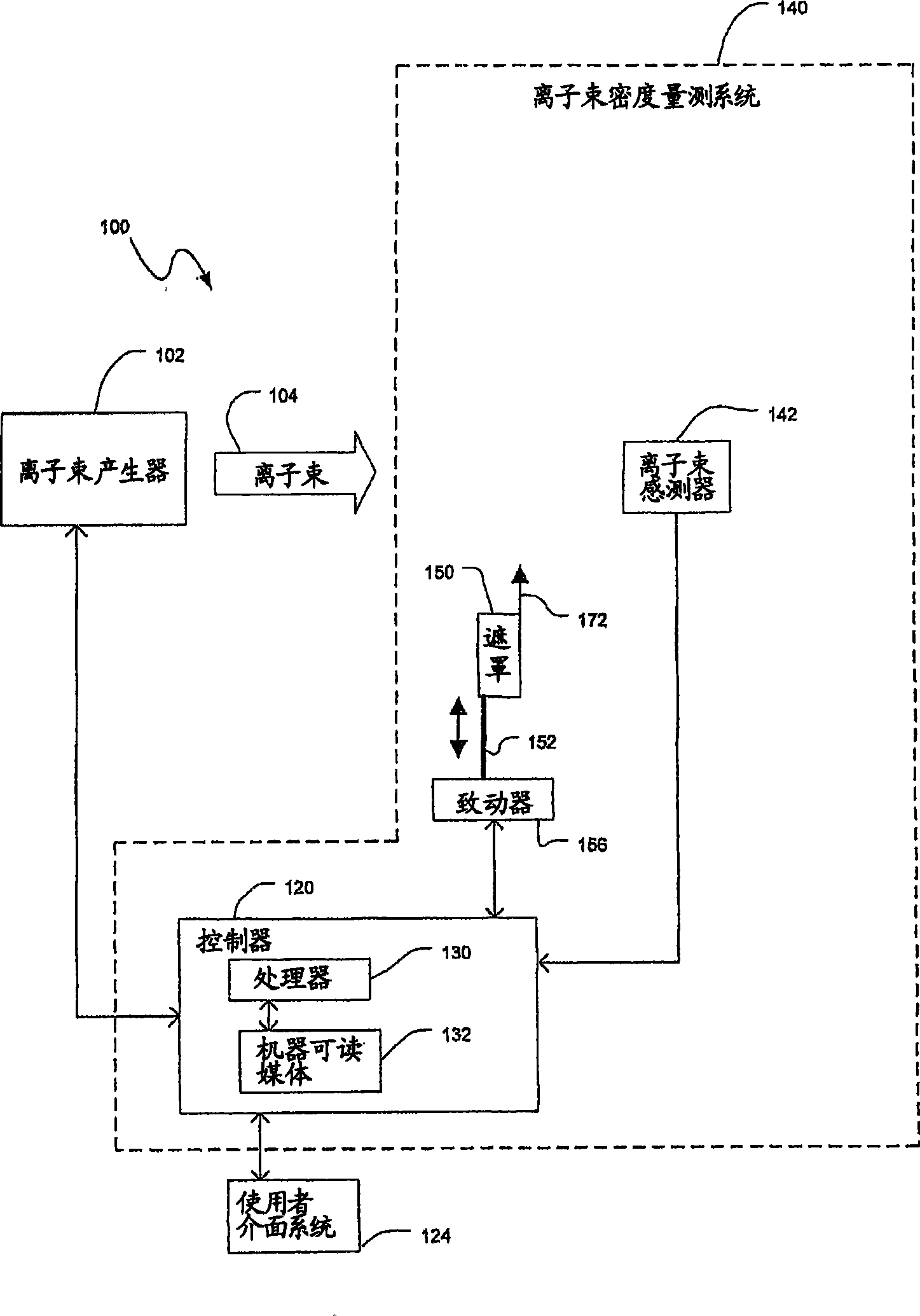

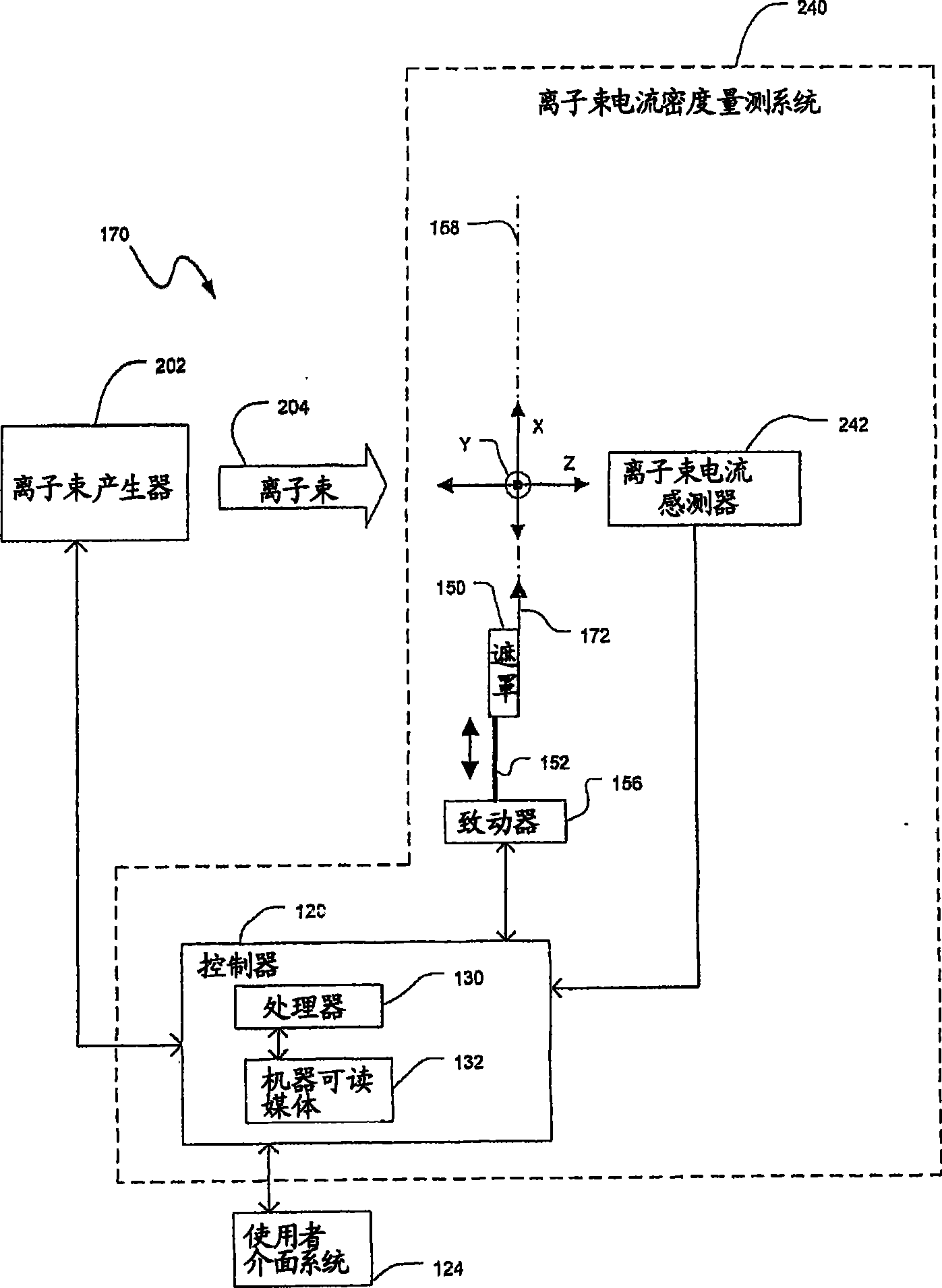

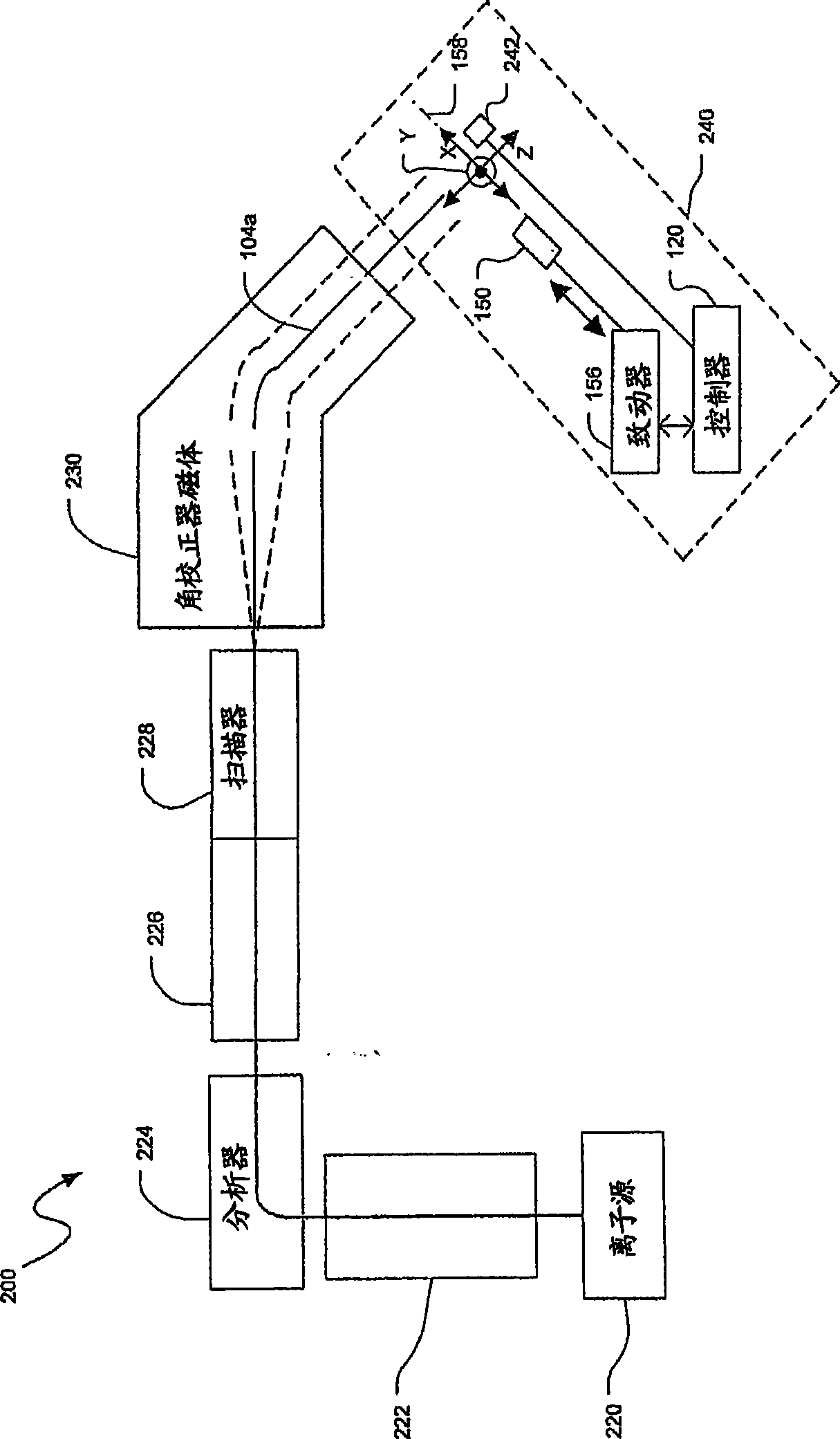

[0090] Figure 1A A block diagram of an apparatus 100 including an ion beam generator 102 and an ion beam density measurement system 140 consistent with an embodiment of the invention is illustrated. The ion beam generator 102 may include various types of components and systems to generate a beam 104 . Beams may include, but are not limited to, ion beams, light beams, electron beams, and neutral particle beams.

[0091] The ion beam density measurement system 140 may include a shield 150 , an actuator 156 , an ion beam sensor 142 and a controller 120 . The mask 150 can be fabricated from a variety of materials to selectively block the beam 104 . Actuator 156 may include one or more motors, drive mechanisms, mechanical linkages, and any other components as known in the art. Actuator 156 may translate mask 150 relative to ion beam sensor 142 by translating mask 150, ion beam sensor 142, or some combination of the two. In an embodiment, the actuator 156 may translate the mask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com