Method for extracting fulvic acid from straw pulp black liquor

A technology of straw pulp black liquor and fulvic acid, which is applied in the field of straw pulp black liquor treatment, can solve problems such as difficult to handle, difficult to decolorize, consume dissolved oxygen, etc., achieve the effect of high price, omit the fermentation process, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

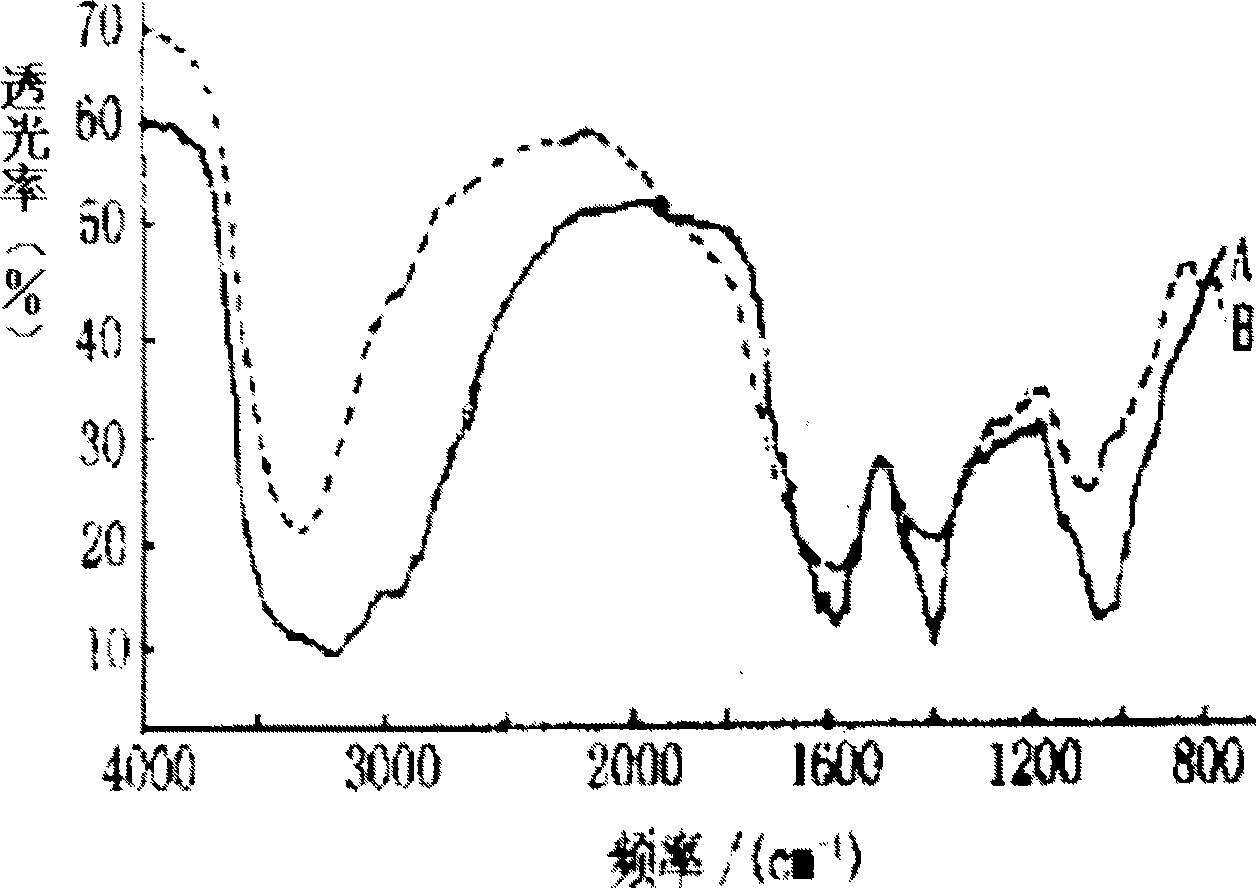

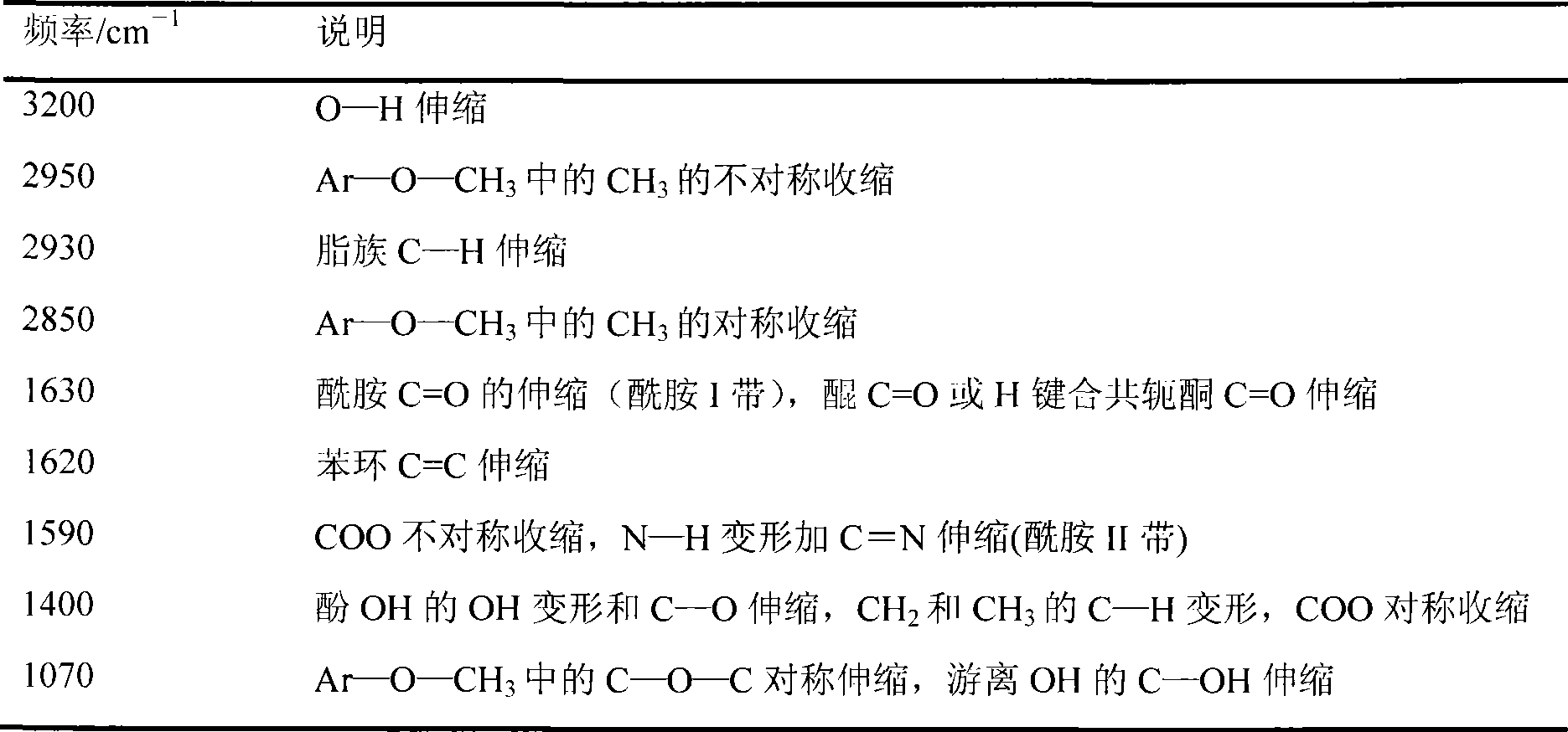

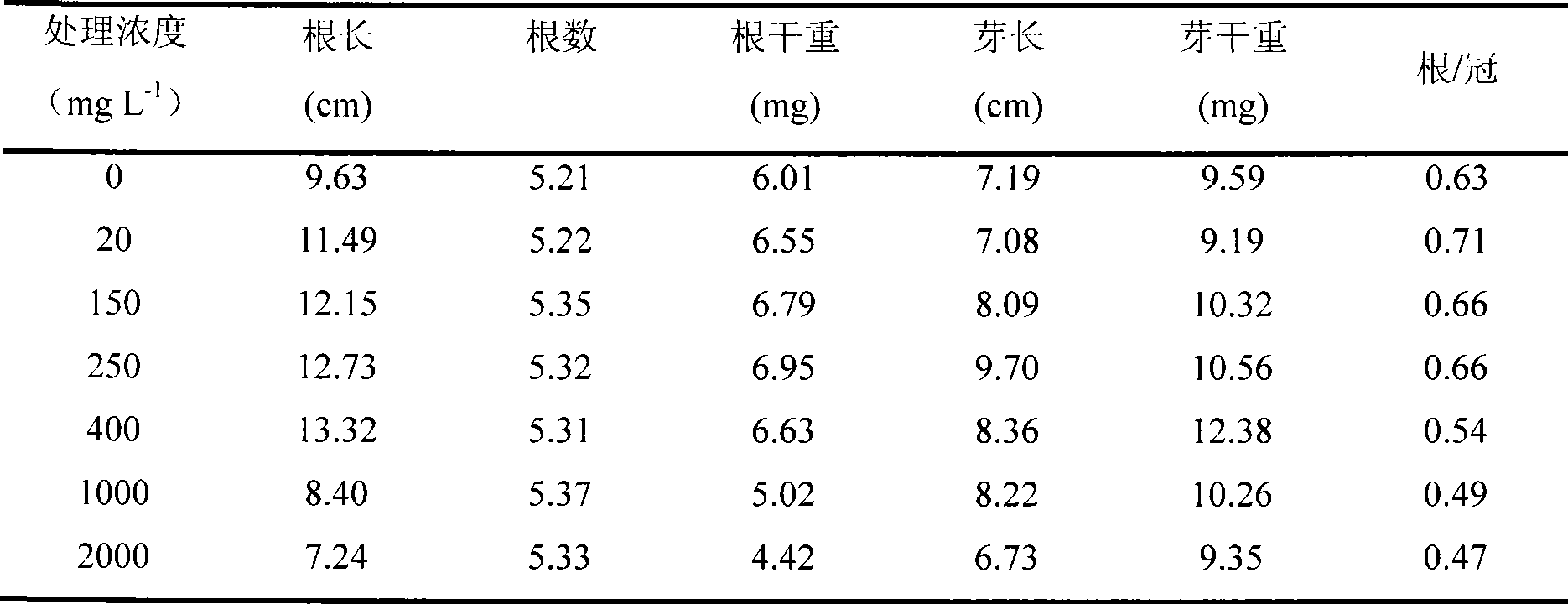

Image

Examples

Embodiment 1

[0038] Mix the black liquor of ammonium method grass pulp and the black liquor of alkali method straw pulp at a volume ratio of 1:100 to obtain mixed straw pulp black liquor; 7; Alkaline straw pulp black liquor has a Baume degree of 2, solid content=4%, pH=9; the mixed straw pulp black liquor is evaporated and concentrated to a solid content of 15.1%, and the Baume degree is 9; promptly obtains the alkaline method and the sub- Ammonium method mixed and concentrated straw pulp black liquor; its pH is 7; the pH of alkali method and ammonium method mixed and concentrated straw pulp black liquor is adjusted to 5 with formic acid, separates out lignin, adds the polyferric sulfate of black liquor weight 2ppm, static Set, and then filter the black liquor, the filtrate is the fulvic acid solution.

Embodiment 2

[0040] Mix the black liquor of ammonium method grass pulp and the black liquor of alkali method straw pulp at a volume ratio of 100:1 to obtain mixed straw pulp black liquor; 10; Alkaline straw pulp black liquor has a Baume degree of 9, solid content=15%, pH=13; the mixed straw pulp black liquor is evaporated and concentrated to a solid content of 65%, and the Baume degree is 40; Mix and concentrate straw pulp black liquor by ammonium method; its pH=11, adjust the pH of the concentrated black liquor to 2 with acetic acid, precipitate lignin, add basic aluminum chloride with a black liquor weight of 50ppm, let stand, and then filter the black liquor , the filtrate is the fulvic acid solution. The fulvic acid solution is dried to obtain fulvic acid.

Embodiment 3

[0042] Mix the black liquor of ammonium method straw pulp and the black liquor of alkali method straw pulp at a volume ratio of 1:10 to obtain mixed straw pulp black liquor; 8; Alkaline straw pulp black liquor has a Baume degree of 5, solid content=7%, pH=10; the mixed straw pulp black liquor is evaporated and concentrated to a solid content of 30%, and the Baume degree is 17; Mix and concentrate straw pulp black liquor by ammonium method; pH=9, adjust the pH of the thick black liquor to 4 with propionic acid, precipitate lignin, add ammonium polyacrylate with a black liquor weight of 5ppm, let it stand, then filter the black liquor, and the filtrate That is, fulvic acid solution. Extract the fulvic acid solution with ion exchange resin to obtain high-purity fulvic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com